作者简介:程宏川(1984—),男,工程师,研究领域为结构仿真及应用

备注

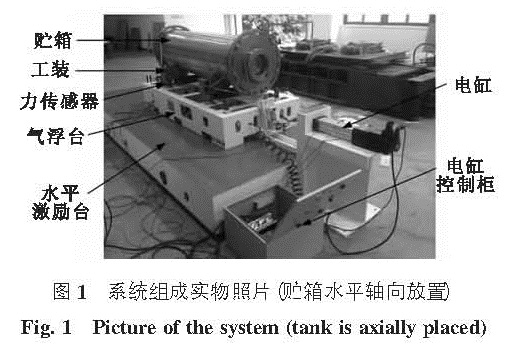

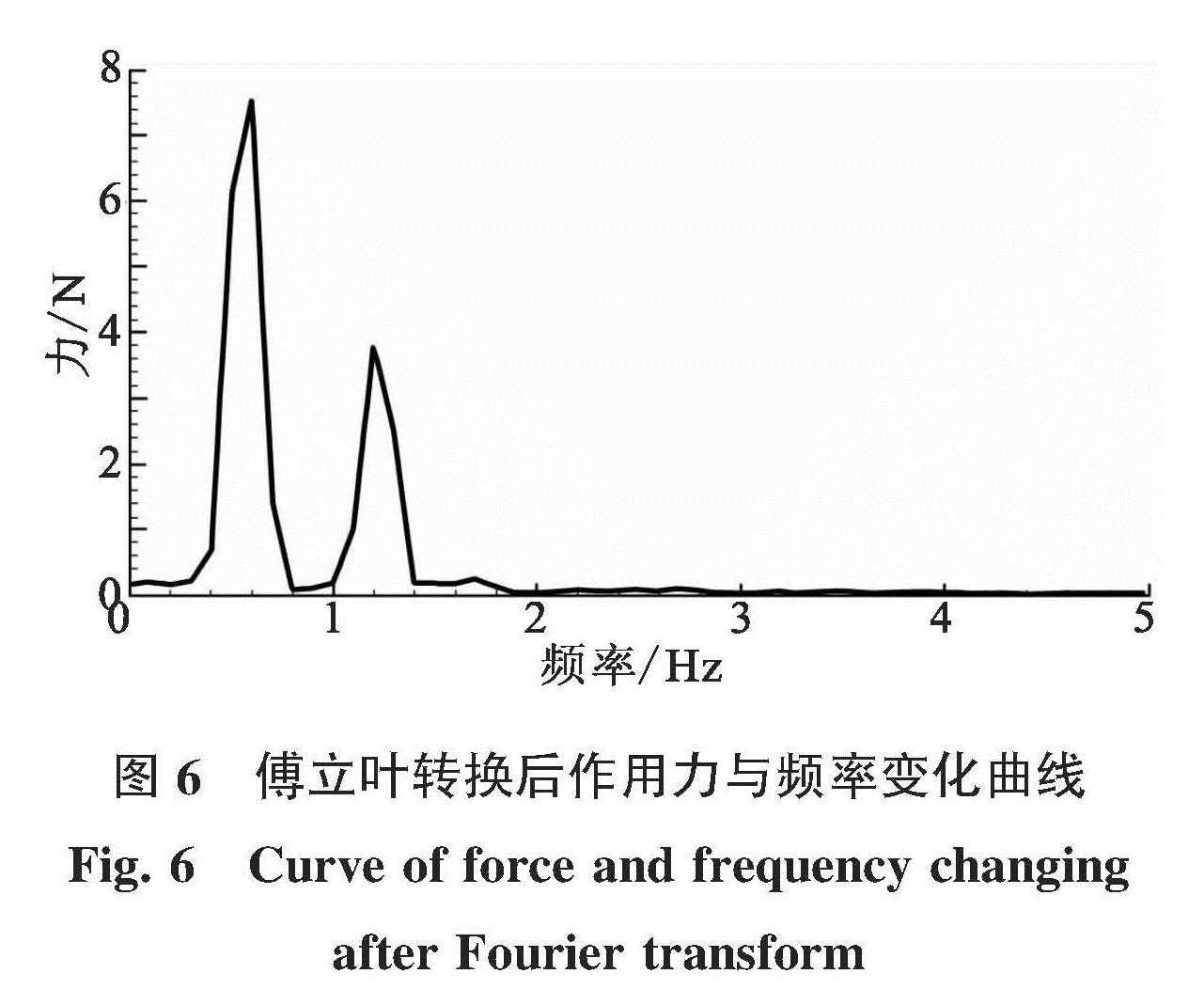

针对某型号大容积贮箱,其晃动特性直接影响到整个系统的动力学特性及轨道控制系统。为了获得该贮箱不同工况下的一阶自由晃动频率,首次提出利用气垫悬浮技术进行贮箱晃动试验的新方法,利用该方法设计出一整套试验系统,该系统包含试验件、激励系统、气浮控制系统、数据采集系统及加注排放系统等。使用试验系统开展不同工况条件下的液体晃动试验,并用CFD软件对该贮箱进行时域分析,结合傅立叶变换最终获得仿真结果。分析比较晃动试验结果、理论计算结果及CFD仿真计算结果,结果显示3种结果一致吻合,测试系统的可靠性和理论CFD仿真结果的正确性均得到验证。

The sloshing characteristics of a type of large volume tank affect the whole system dynamic characteristics and orbit control system directly. In order to get the free sloshing frequency of the tank under different working conditions, a new method of tank liquid sloshing test based on air cushion flotation technology is proposed. A set of experiment system, including tank, excitation system, air flotation control system, data acquisition system and filling & draining system, is designed by this method to solve the liquid sloshing problem under different working conditions. The final simulation results were achieved by Fourier transform and time domain simulation analysis results obtained by CFD software. The results indicate that the test result, theory result and the CFD simulation result are consistent, and prove that the test system is reliable and the simulation results of CFD are correct. The test results provide an important reference and supporting data for tank design optimization and launch vehicle attitude & orbit control system design optimization.