作者简介: 王海韵(1992—),男,硕士,研究领域为航空宇航推进与工程

备注

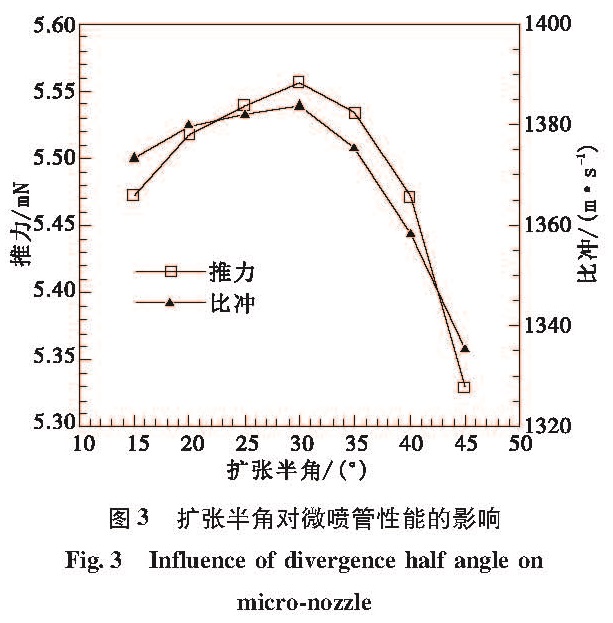

微喷管设计加工方法不同于常规尺寸喷管,具有小尺寸、大面积-体积比的特点,内部流动雷诺数低,粘性力影响显著。为研究结构参数设计对蒸发液体微推力器喷管性能的影响,利用三维数值模拟方法研究不同扩张半角、面积比以及刻蚀深度对微喷管推力、比冲的影响。结果 显示,增加微喷管扩张半角有利于降低粘性损失,最优扩张半角为30°,其数值大于常规尺寸喷管。增加面积比可以提高气体膨胀程度,但与之同时增加的壁面面积会增加粘性损失,推力、比冲先随面积比增加而增加,面积比为14时达到峰值,随后下降。增加刻蚀深度有利于减小扩张段壁面面积,提高微喷管性能。

The micro-nozzle is remarkably different from traditional macro-nozzle owing to its tiny size,large area-to-volume ratio,low Reynolds number,notable viscous influence and special fabrication.The effects of different divergence half angles,area ratios and etching depths on thrust and specific impulse of the micro-nozzle were studied with the numerical simulation method to investigate the influence of structure parameters on micro-nozzle performance of vaporizing liquid micro-thruster.The results indicate that the larger divergence half angle of the micro-nozzle is in favour of reduction of viscous loss; the best divergence half angle of the micro-nozzle is 30°,which exceeds that of the traditional macro-nozzle; larger area ratio can improve gas expansion coefficient,but it increases viscous loss due to the addition of divergence wall area; both the thrust and specific impulse increase at first with the growth of area ratio until a peak value at 14,where the micro-nozzle perform best and then they decrease; increase of etching depth is beneficial to promote the performance of micro-nozzle.