作者简介: 沈文金(1984—),男,工程师,研究领域为液体火箭发动机涡轮泵设计

备注

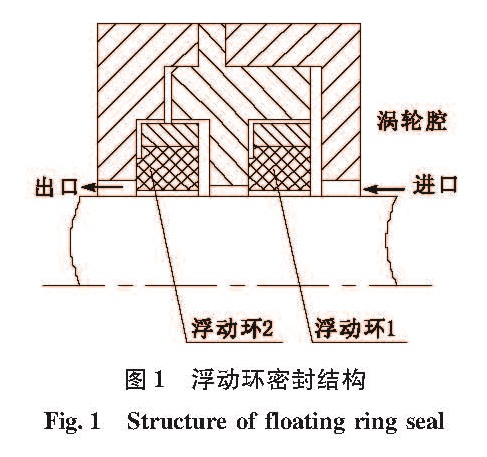

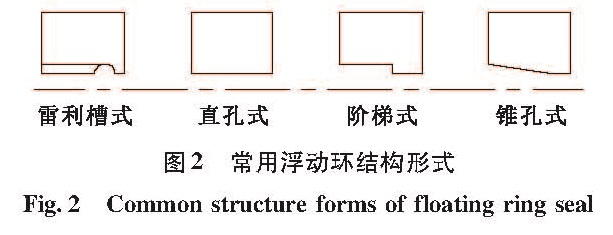

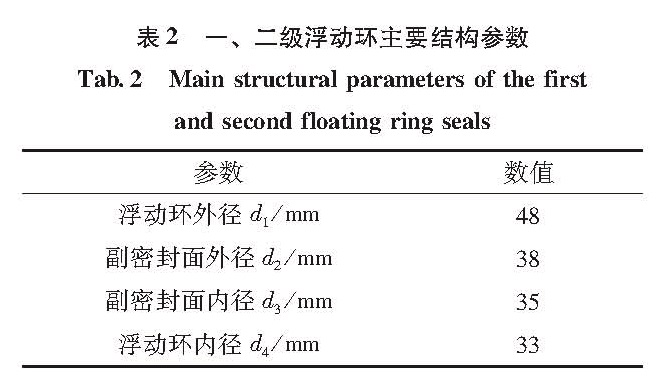

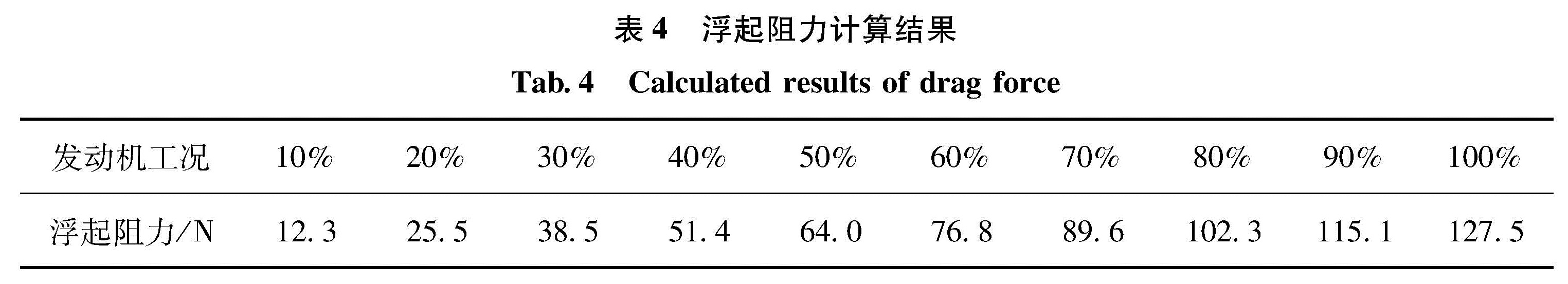

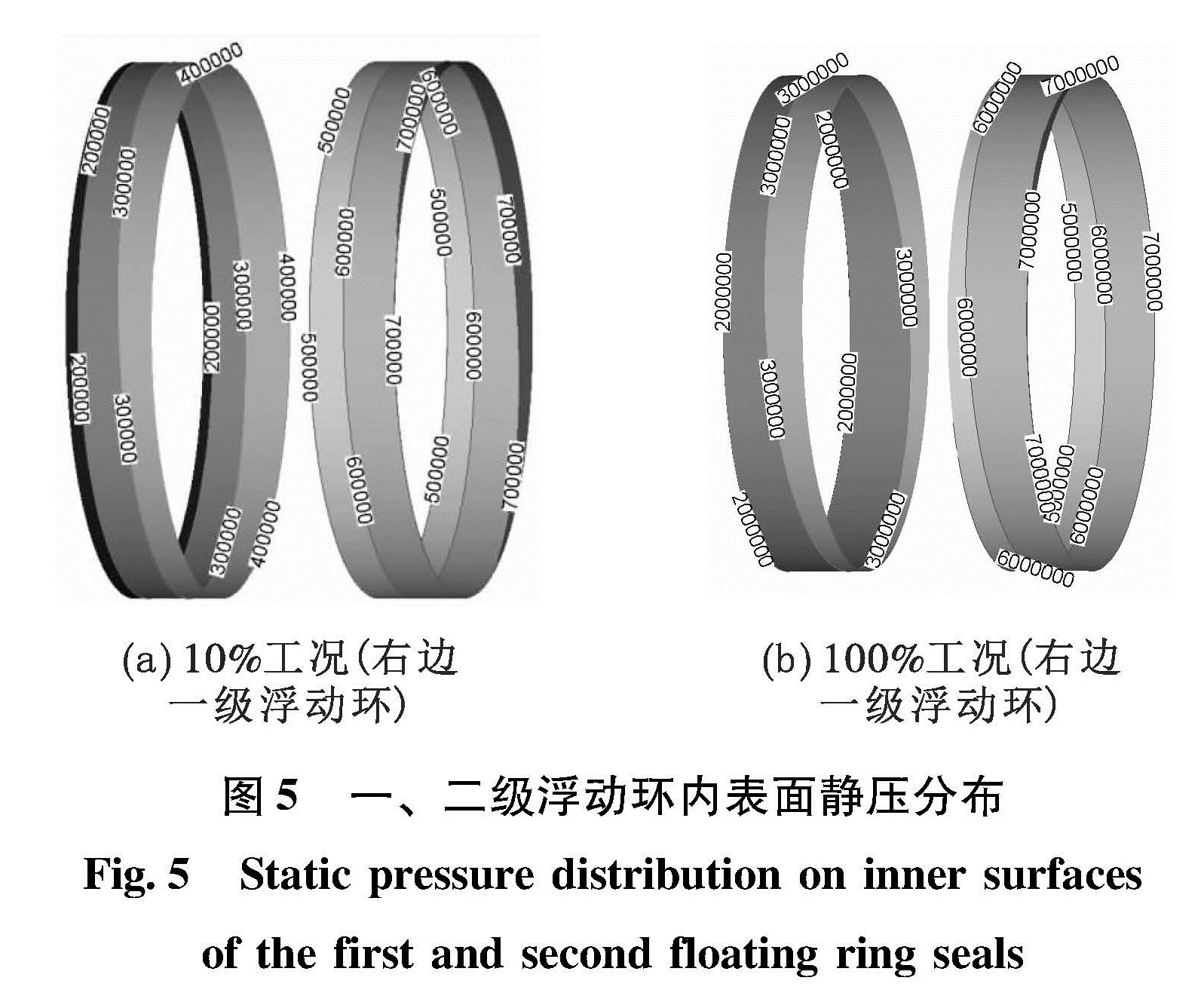

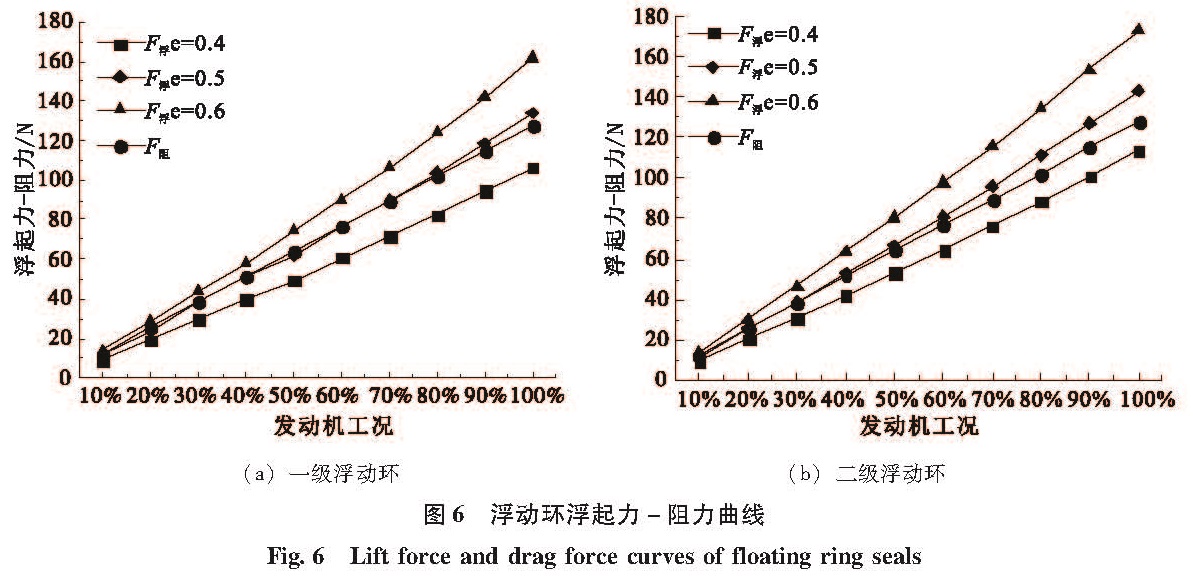

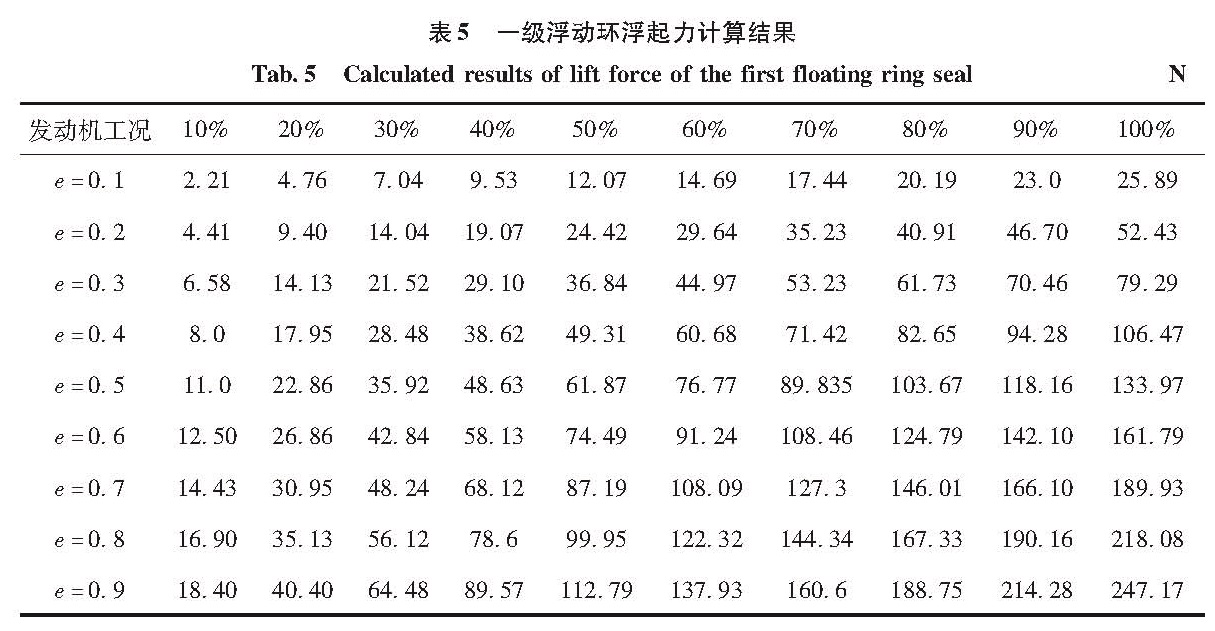

按照我国载人航天登月需求,正在开展多次起动、10%~100%深度变推力80 kN液氧/甲烷发动机关键技术研究。氧涡轮泵作为发动机的核心组件,采用的浮动环密封变工况工作适应性将直接影响到涡轮泵工作的安全性和可靠性。依据发动机系统变推力要求,采用数值计算方法对浮动环密封进行不同推力工况、不同偏心率条件下的浮起力计算,并与一维方法计算的浮起阻力结果进行对比分析,确定全工况范围内一、二级浮动环工作时偏心率介于0.4~0.6之间,浮动环泄漏量约为2.58~39.4 g/s。浮动环在此偏心率范围内工作可靠性高,可以有效地避免浮动环碰磨、崩边,具备大范围变工况工作能力,满足涡轮泵安全性工作和发动机深度变推力工作要求,可以为涡轮泵方案论证及设计提供理论依据。

According to the demands of the manned space program,the project of the LOX/CH4 engine key techniques needs to be studied for the multi-startup and 10%~100% deep throttling capability,whose thrust is 80 kN.The variable thrust adaptability of the floating ring seals in the engine would affect safety and reliability of the oxygen turbopump assembly as one of the core components in rocket engines.In this paper,according to variable thrust requirements of the engine system,the floating force of the floating ring seals under the conditions of different thrust and eccentricity ratio is calculated with the numerical method,which is compared with drag force calculated with one-dimensional formula.Based on the above measures,the eccentricity ratio(0.4~0.6)of the first and second floating ring seals working at full work conditions,and the leakage rate of 2.58~39.4 g/s are determined.Working within the range of this eccentricity ratio,the floating ring seals has high reliability and capability of working in changing conditions with a wide range,the rubbing or breaking of its edge can be avoided,which can satisfy safety requirements of the turbopump and deep throttling requirements of the engine.The results could provide a theoretical foundation for turbopump project approach and design.