作者简介: 张连万(1985—),男,工程师,研究领域为增压输送系统阀门设计

备注

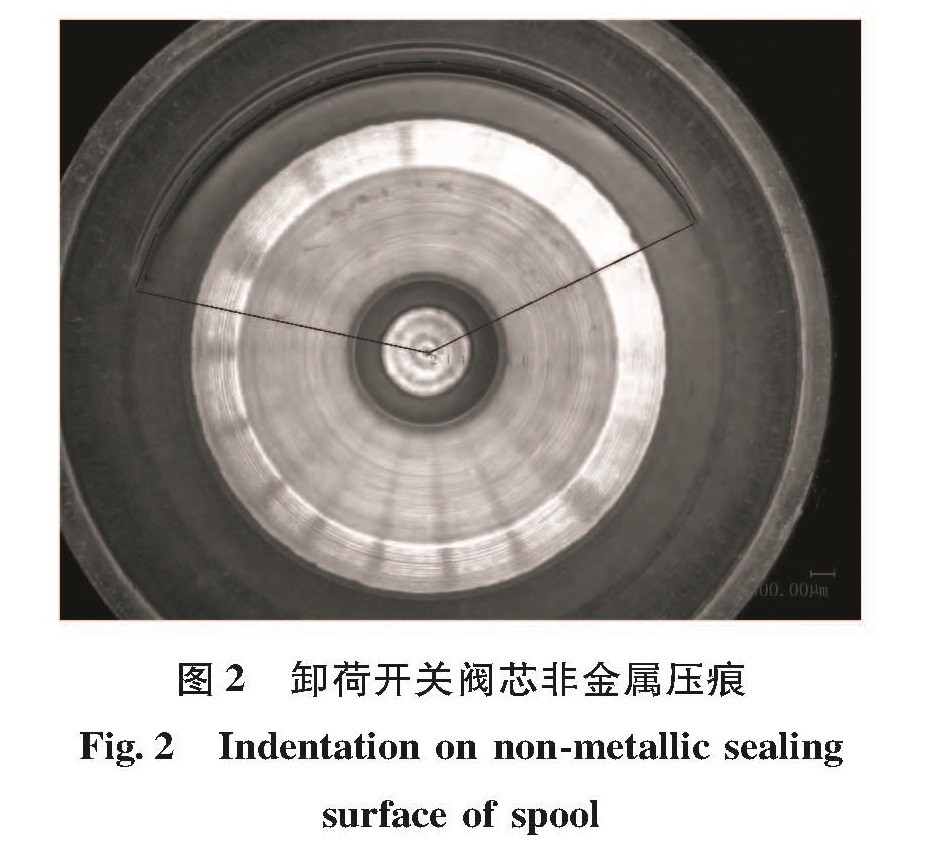

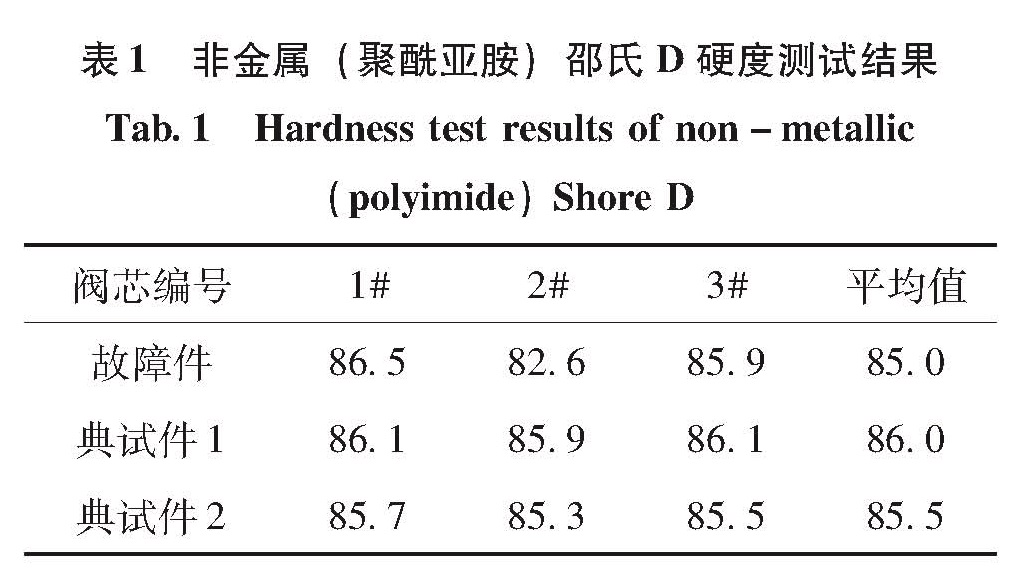

某发射场进行火箭发动机气瓶充气时出现充气卸荷开关关闭后泄漏故障,分解卸荷开关后发现卸荷开关阀芯导向部位存在异常磨损,且阀芯非金属密封面周向密封压痕深度不均匀,结合故障形貌,采用有限元仿真计算压痕深度,对泄漏故障的根本原因进行深入剖析。分析结果表明:卸荷开关阀芯导向部位存在微小原始缺陷,多次动作后在阀芯与壳体导向部位产生粘着磨损,阀芯在壳体导向孔中回位发生偏斜,造成阀芯非金属密封面出现不均匀压痕,最终导致卸荷开关在测试时漏率超标。

When inflating gas to a gas vessel of rocket engine at a launching site,a leakage phenomenon occurred after the unloading valve was closed.Abnormal wear of the spool's guiding part and an uneven indentation on non-metallic sealing surface were found by integrating the macro observation and micro morphology after breaking the valve.The finite element method is used to establish the model of spool and valve seat.It has verified that the calculated indentation depth is close to the measured depth.The analysis results indicate that there exists some tiny original defects in the spool's guiding part of unloading valve,and adhesive wear appears due to the repeated motion between the spool's guiding part and the guiding hole,which caused the return deflection of the spool in the guide hole and uneven indentation in non-metallic sealing surface,eventually led to leakage of unloading valve during the test.