作者简介: 赵 剑(1986—),男,博士,研究领域为液氧/煤油发动机总体设计与优化

备注

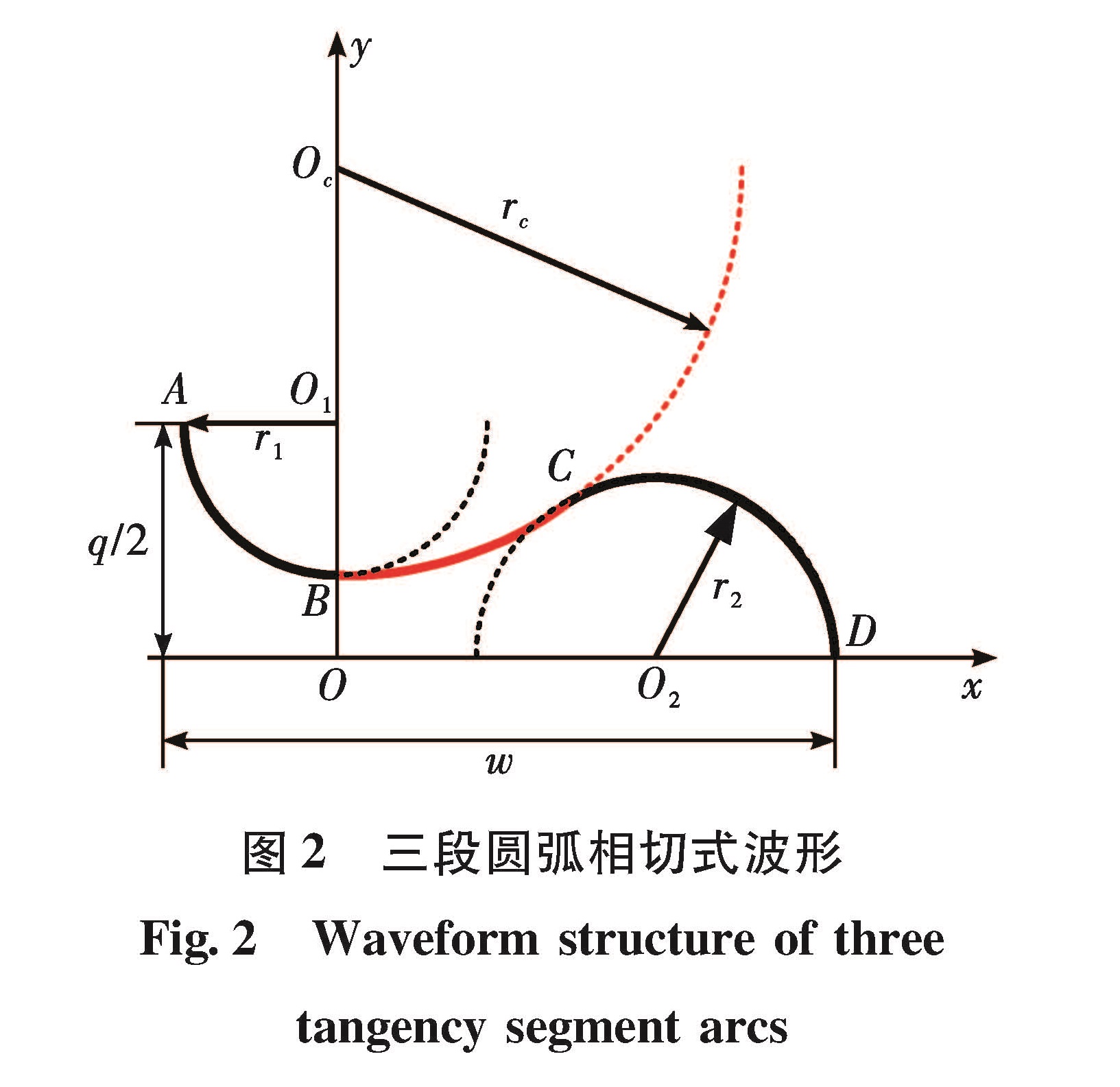

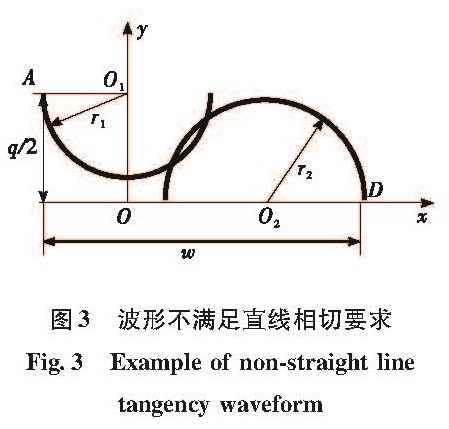

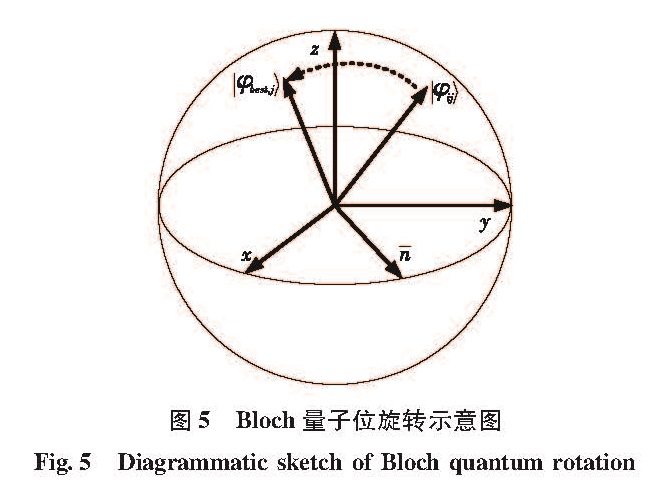

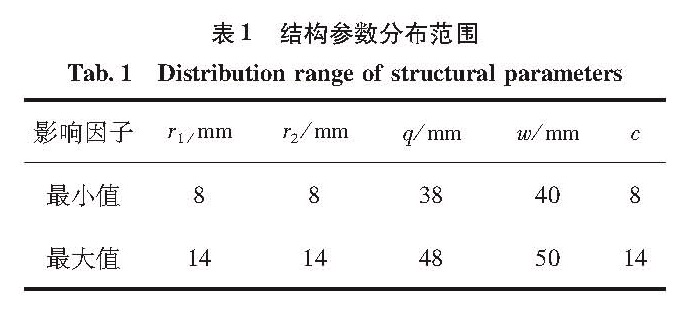

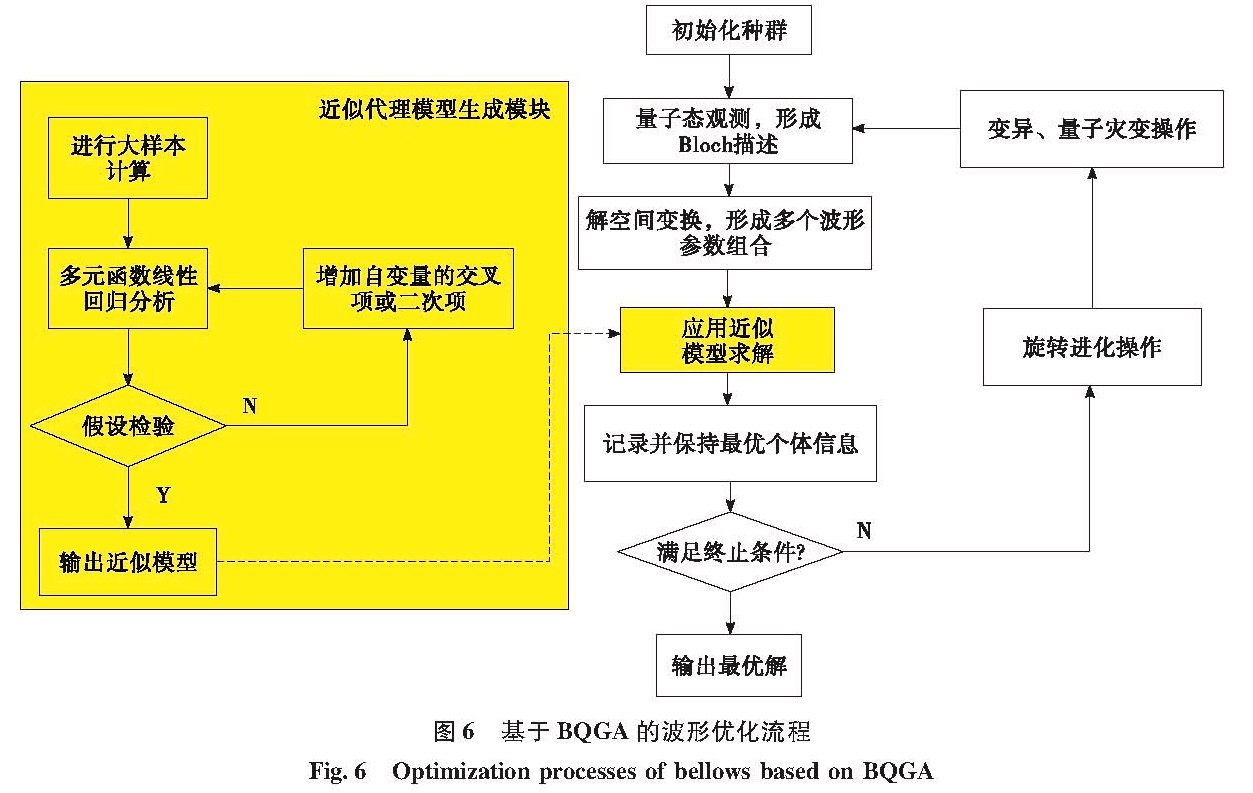

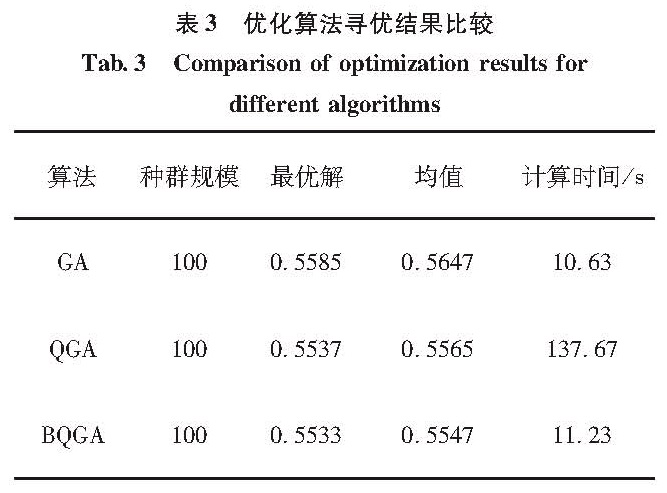

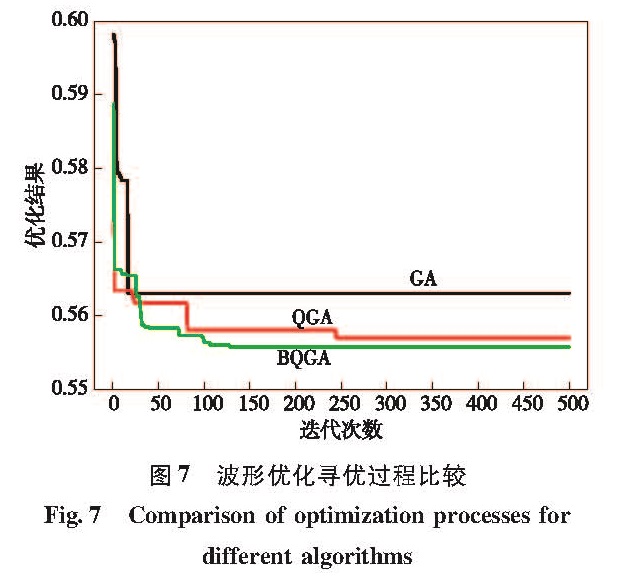

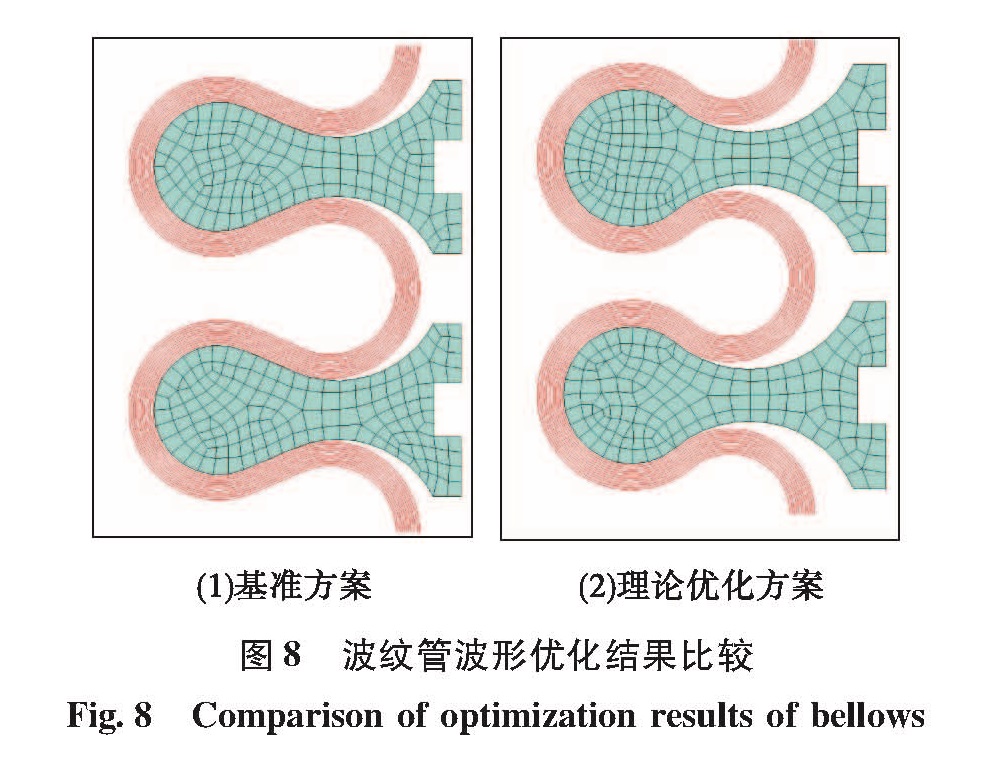

适用于高温、高压、富氧燃气的柔性摇摆组件是我国重型液氧/煤油发动机“泵后摇摆”总体布局的核心组件,也是首先需要攻克的关键技术之一。为了从多波形参数匹配的细观角度揭示波形参数之间的敏感度关系,以及波形参数对结构特性的影响机理,将波形优化问题提炼为多变量、多目标的最优化问题,基于参数化非线性有限元仿真程序和量子位Bloch球面坐标的量子遗传算法(BQGA)进行协同优化。同时,在优化流程中,采用多项式响应面模型代替直接有限元求解,提高了优化效率。研究结果给出了最优波形方案,相对于基准波形,优化波形的承压能力提高了8.6%,而变形补偿刚度减少了41.32%。

China's heavy LOX/kerosene engine will adopt a new overall layout which is named as “swing behind the pump”, in which the flexible swaying assembly must bear high temperature, high pressure and oxygen enriched gas, and is one of the key technologies needing to be overcome first. The multi-layer bellows is a flexible joint which is used to compensate the deformation when the engine sways. In order to uncover the sensitivity relationship between waveform parameters of bellows from the microscopic view, as well as the their effects on the structural characteristics, the waveform optimization of the flexible bellows is regarded as a multivariable and multi-objective optimal problem, and the collaborative optimization are conducted base on parametric nonlinear finite element program and Bloch quantum genetic algorithm(BQGA). In addition, the polynomial response surface model is also used in the optimize process instead of direct finite element solution, which is great helpful for improving the optimization efficiency. The optimal waveform of bellows was obtained. The results indicate that, compared to reference bellows, the pressure-bearing capacity of optimal bellows is increased by 8.6%, while the deformation compensation stiffness is reduced by 41.32%.