作者简介: 李晓鹏(1989—),男,硕士,研究领域为特种橡胶密封制品开发

备注

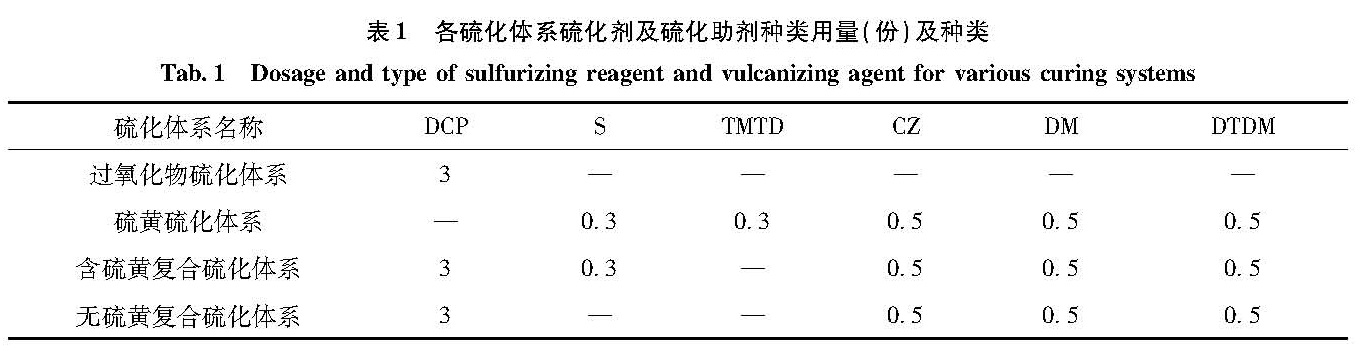

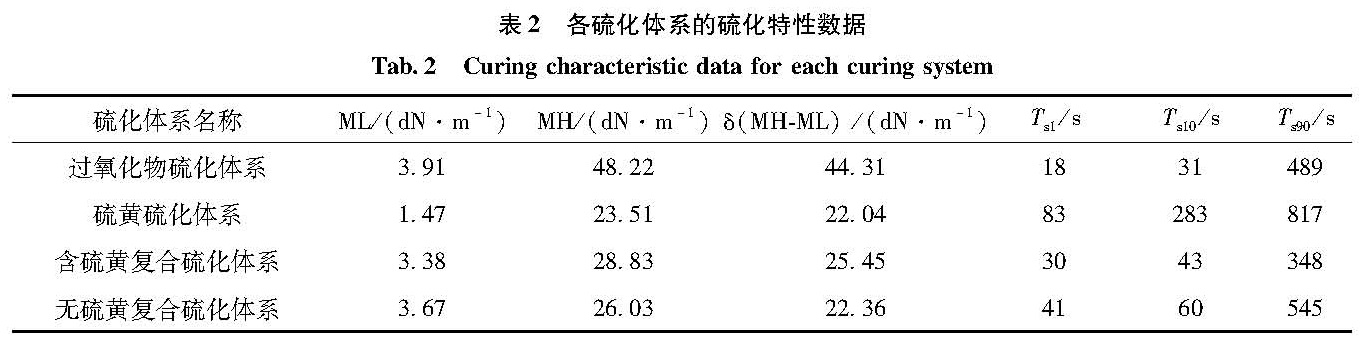

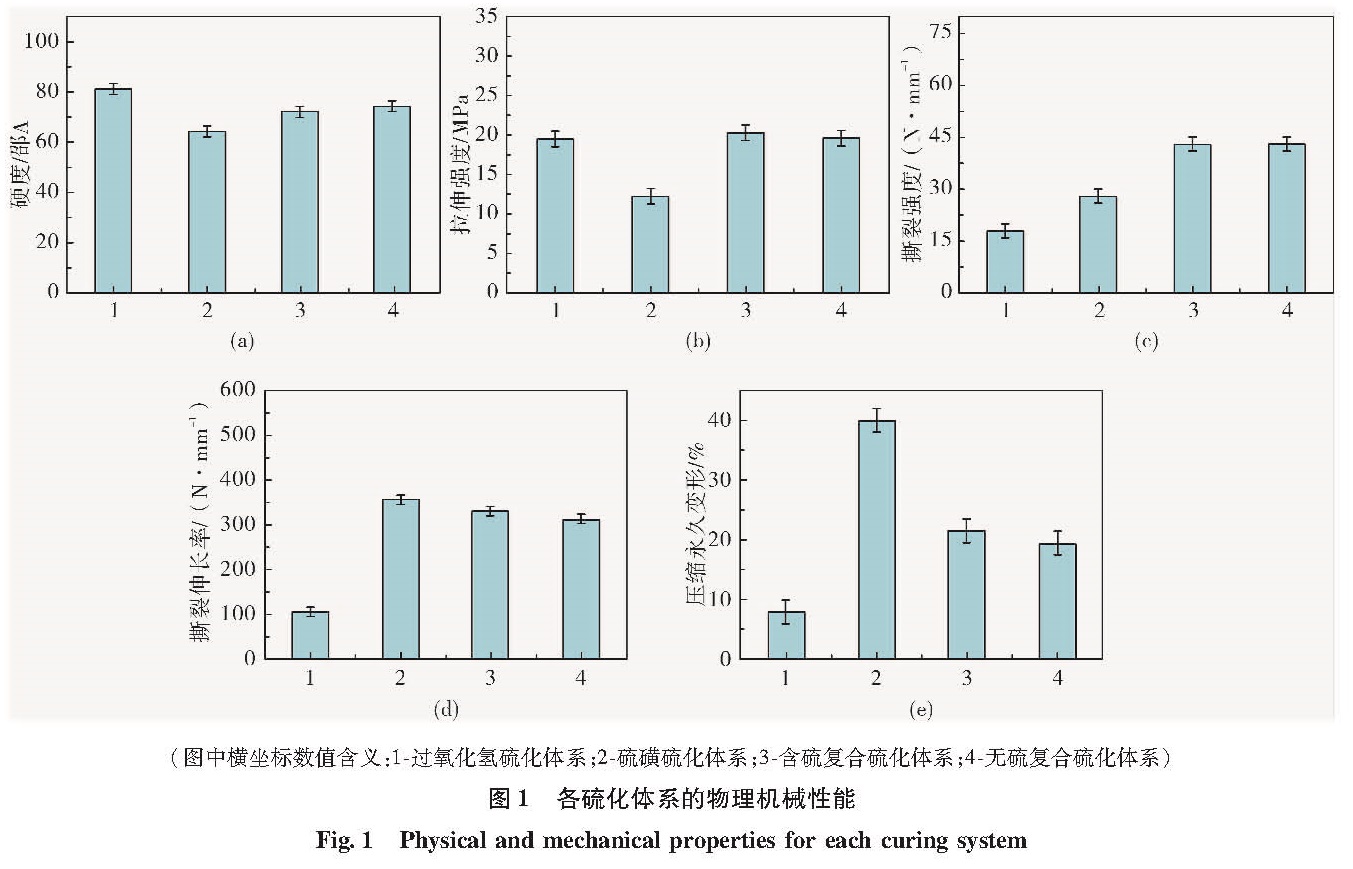

研究了过氧化物硫化体系、硫黄硫化体系、含硫黄复合硫化体系以及不含硫黄复合硫化体系对三元乙丙橡胶复合材料力学性能以及工艺性的影响。研究结果表明:采用过氧化物硫化体系制备的复合材料交联密度要远高于其它三种硫化体系,而促进剂会影响过氧化物的交联效率; 采用过氧化物硫化体系制备的硫化胶,其拉伸强度以及耐压缩永久变形性能最佳,而含硫黄硫化体系具有优异的抗撕裂性能; 过氧化物硫化体系容易造成产品分模线撕裂,而含硫复合硫化体系可以显著改善这一状况; 硫黄以及促进剂容易造成三元乙丙橡胶的喷霜。最后,不含硫的复合硫化体系具有最佳的力学性能以及工艺性能,可以广泛地应用于三元乙丙橡胶的配方设计。

The influence of the hyperoxide curing system,sulfur curing system,compound curing system with sulfur,compound curing system without sulfur on the mechanical properties and process properties of ethylene propylene diene monomer(EPDM)composite material is studied. The results show that the crosslinking density of EPDM composite material prepared by hyperoxide curing system are higher than that of other three composite materials,nevertheless the accelerant agent would affect the crosslinking efficiency of hyperoxide; the tensile strength and compress permanent deformation of EPDM composite material are the best,and the tear strength of EPDM composite material prepared by curing system with sulfur is better than that of EPDM composite material prepared by hyperoxide curing system. Besides,the hyperoxide curing system is easy to cause the product parting line tear,but the compound curing system with sulfur can improve the product surface tear obviously; the sulfur and accelerant agent may easily cause the blooming of EPDM. The compound curing system without sulfur have the best mechanical properties and process properties, and can be widely applied to the formula design of EPDM.