作者简介:杜永清(1975—),男,高级工程师,研究领域为液体火箭发动机试验

备注

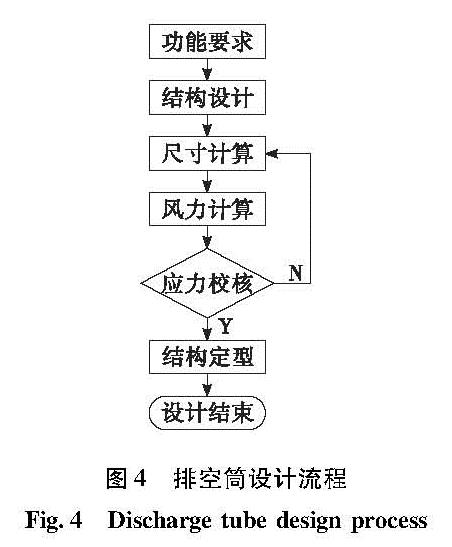

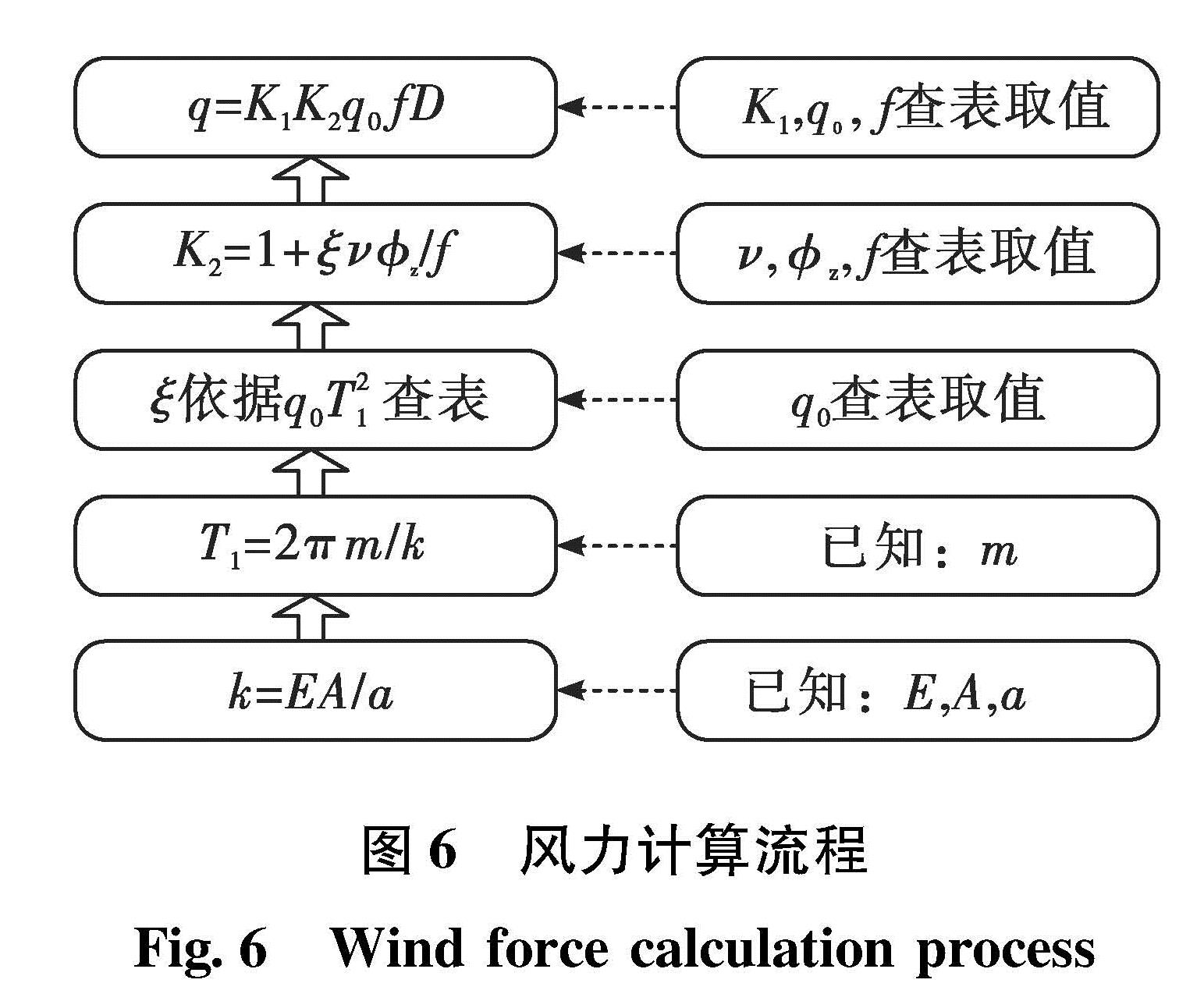

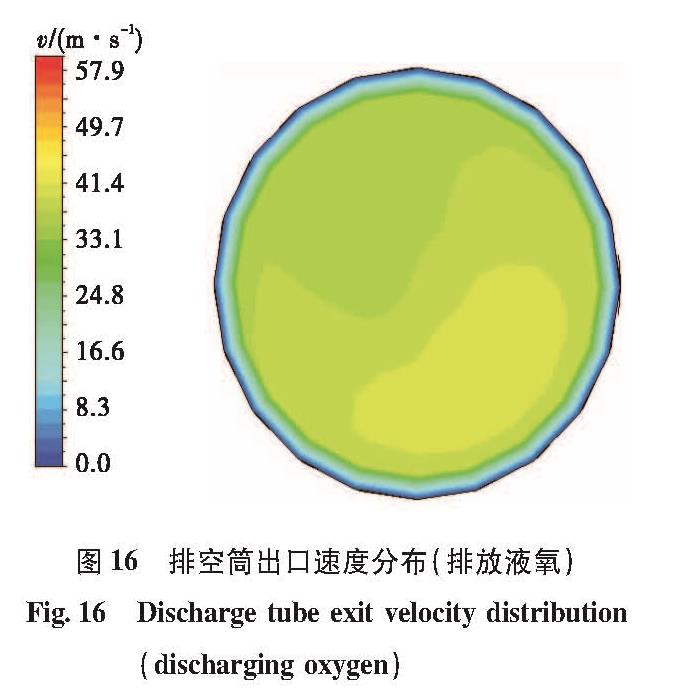

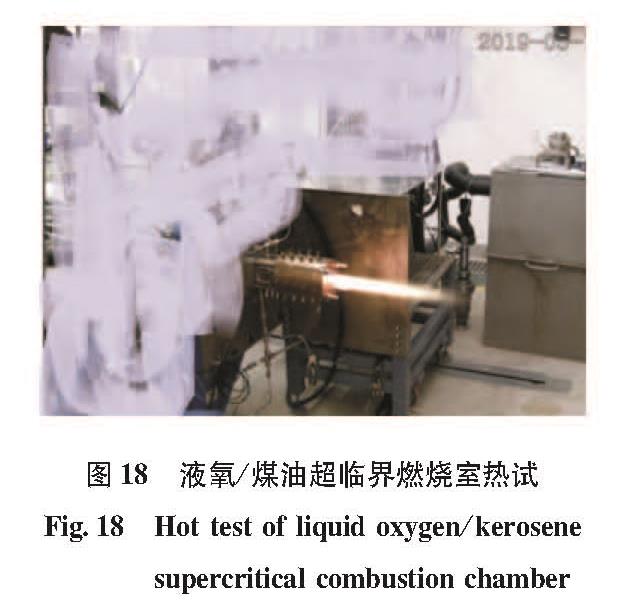

针对液氧/甲烷、液氧/煤油等火箭发动机地面试验中氧/甲烷排放易出现重气云、易燃易爆危险性高等问题,设计一种安全排空装置,总体结构为下部是收集箱,上部是排空筒。采用功能驱动设计、应力校核尺寸的方法,对排空装置的收集箱、排空筒、固定支架几个关键部件进行了结构设计。设计结果为:收集箱是内部焊接有角钢骨架的钢板结构,钢板截面应力为0.4 MPa,远低于允许应力,人孔通过低温橡胶密封; 排空筒下部是花管结构,插入收集箱与其联通,中部焊接排放接嘴,所受平均风力为111.2 N/m,引起的最大弯曲正应力为1.45 MPa,切应力为0.01 MPa,安全系数均很高; 固定支架螺栓所受应力幅为2.1 MPa,低于许用值9.7 MPa。利用数值分析工具,仿真了排空装置工作过程,分析结果为:收集箱内最大压力为0.107 MPa,排放接口处最大冲击载荷为0.72 MPa、出口平均流速为45 m/s,均符合强度要求和安全排放要求。加工的排空装置多次成功应用于相关试验,结果表明:该排空装置设计方法可行,结构可靠,实现了预期功能,保证了氧/甲烷等易燃易爆介质的安全排放。

In view of the problems of heavy gas cloud and high risk of inflammability and explosion in oxygen/methane emission in the ground test of liquid oxygen/methane, liquid oxygen/kerosene and other rocket engines, a safe emission device was designed.The lower part of the general structure is collection box, and the upper part is evacuation tube.Using the method of function drived design and stress checking size, the structure design of several key parts of the emission device, such as collecting box, emptying tube and fixing bracket, were carried out.The design results were as follows: the collection box was a steel plate structure with angle steel frame welded inside.The section stress of the steel plate was 0.4 MPa, much lower than the allowable stress.The manhole was sealed by low-temperature rubber.The lower part of the evacuation tube was a flowered tube structure, which was inserted into the collection box and connected with it, and the middle part was welded to discharge nozzle.The average wind force in the suburbs of Xi'an was 111.2 N/m, and the maximum bending normal stress caused by it was 1.45 MPa, and the shear stress was 0.01 MPa, both of which had high safety factors.The stress amplitude of the bolt with fixed support was 2.1 MPa, lower than the allowable value of 9.7 MPa.The working process of the emission device was simulated by the numerical analysis tool.The analysis results were as follows: the maximum pressure in the collection box was 0.107 MPa, the maximum impact load at the discharge interface was 0.72 MPa, and the average outlet flow rate was 45 m/s, all of which met the requirements of strength and safe discharge.The emission device had been made and applied in relevant tests successfully for many times.The test results showed that the design method was feasible and the structure was reliable, realizing the expected function, which ensured the safe discharge of flammable and explosive media, such as oxygen and methane.