作者简介:胡海峰(1986—),男,博士,高级工程师,研究领域为液体火箭发动机数字化设计技术

备注

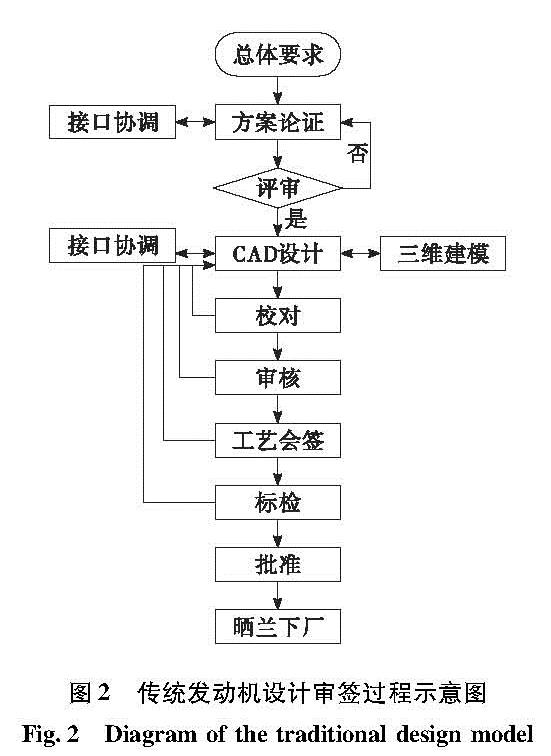

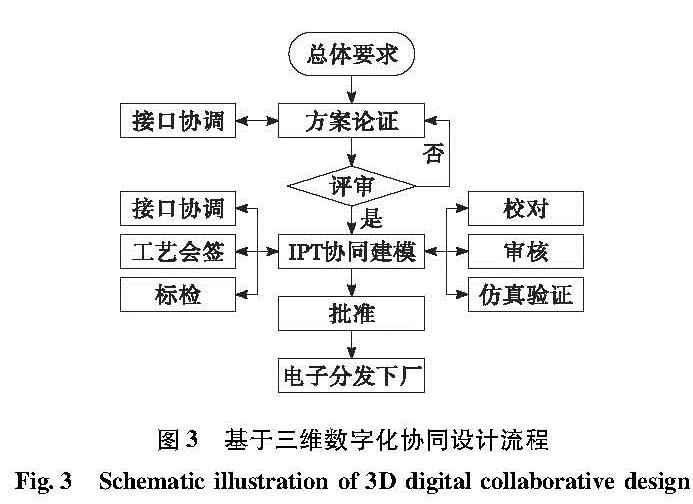

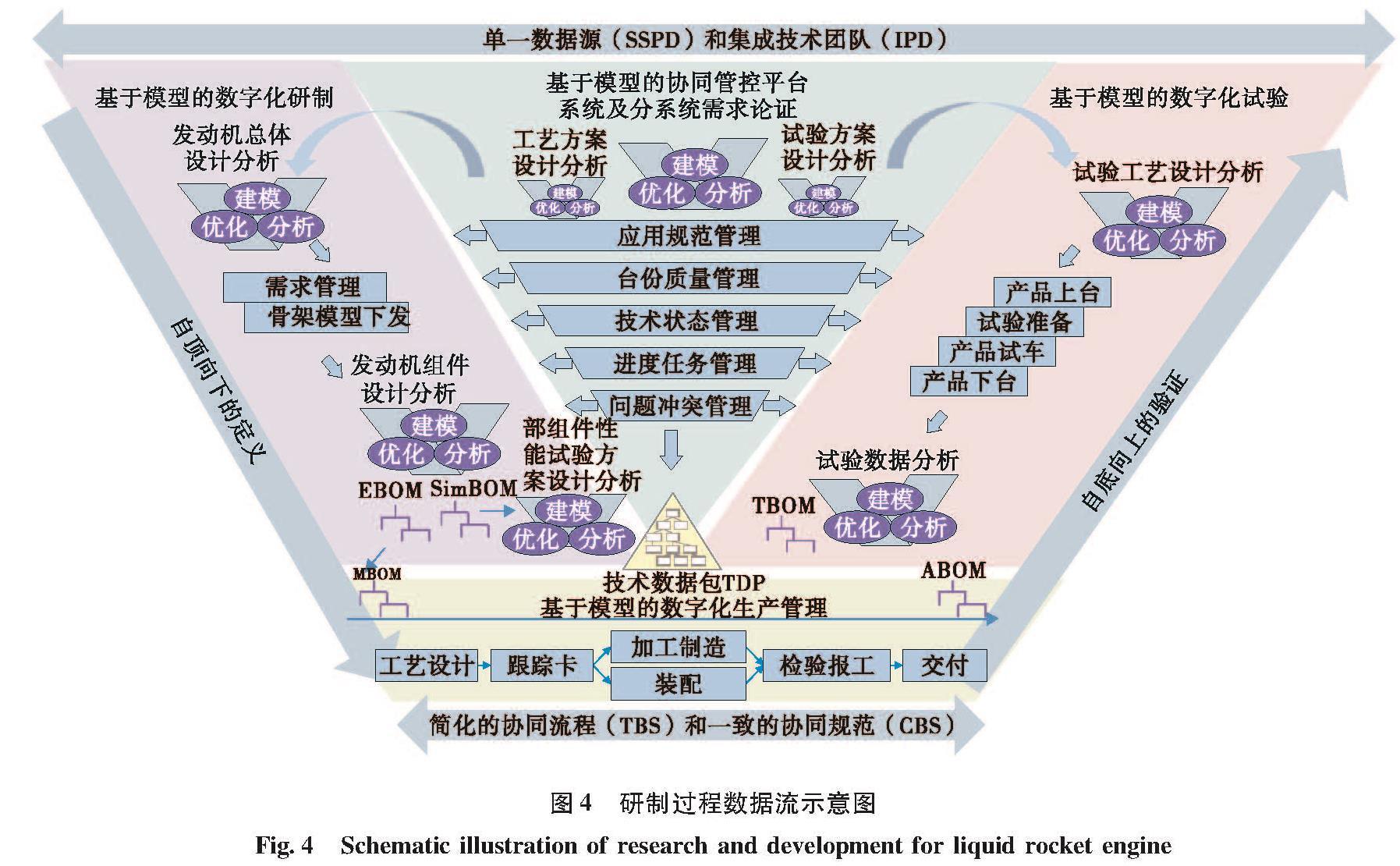

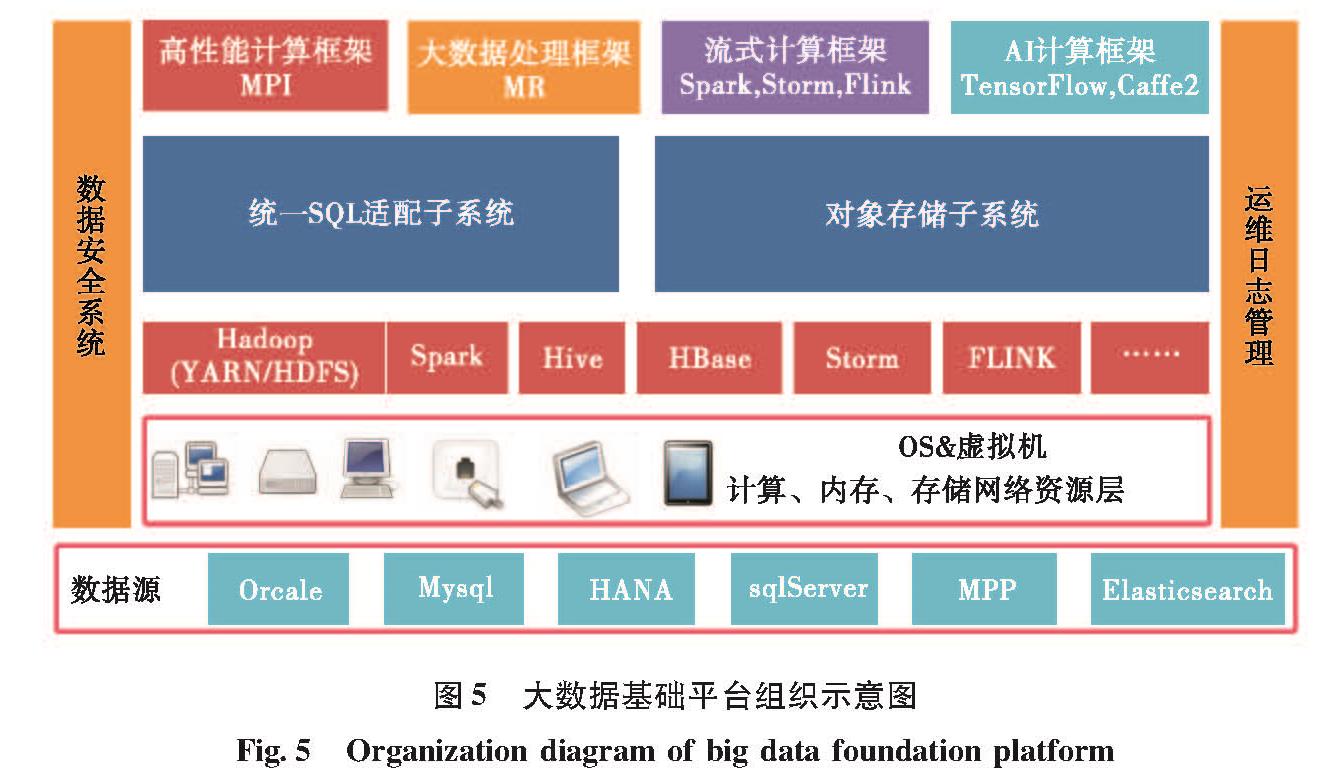

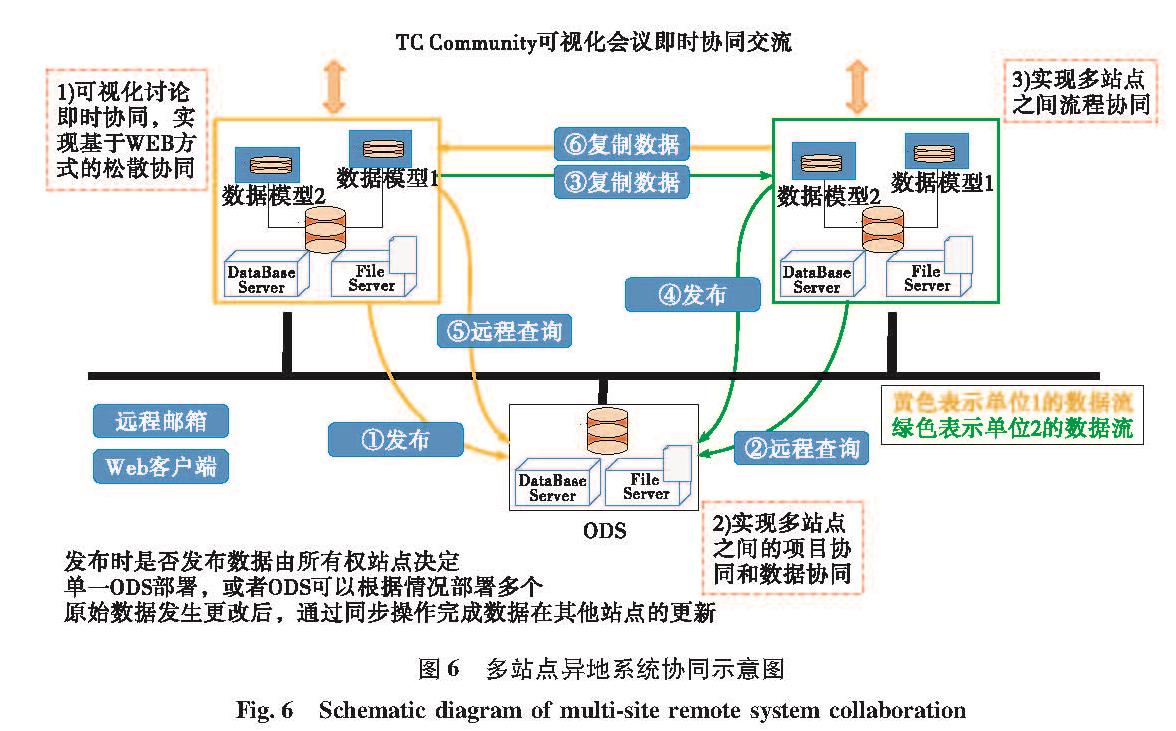

针对液体火箭发动机协同设计工程实际需求,围绕研制数据高效流转与协同,面向产品全生命周期跨地域、跨专业特点,提出了协同设计平台框架。针对协同平台中的5项关键技术,给出了相应解决途径。基于PLM系统构建协同环境,建立统一编码,整合研制过程中的标准件、原材料等共性基础数据; 通过基于MBD的三维结构设计,采用MBSE理念,以模型为载体升级发动机设计流程; 采用线上IPT模式提升产品设计效率,同时实现全过程数据记录知识累积。采用BOM结构组织和展示不同设计阶段形成的数据; 基于Hadoop平台分布式数据存储模式,实现结构化和非结构化数据综合管理。通过工程实践验证表明,构建的协同平台实现了基于数字化模型的设计工艺定制化协同,科研生产全过程的信息整合和多维度监控,促进了业务流程持续优化和研制效率不断提升,支撑发动机研制模式的转型升级。

According to the requirement of liquid rocket engine development, the framework of collaborative design platform is proposed.The platform is focused on the efficient transfer and collaboration of research data, and the cross-region and cross-professional characteristics of the product's full life cycle.Five key technologies in the collaborative platform are analyzed and the corresponding solutions are proposed.Based on the PLM system, collaborative environment is built, unified coding is established, and common basic data such as standard parts and raw materials are integrated in the development process.Through the MBD-based three-dimensional structure design, the MBSE concept is adopted to upgrade the engine design process with the model as the medium.The online IPT mode is adopted to improve the efficiency of product design, and the data recording in the whole process is also realized.BOM is used to organize and display data formed at different design stages.Based on the distributed data storage mode of Hadoop platform, comprehensive management of structured and unstructured data is achieved.The verification through engineering practice shows that the constructed collaborative platform realizes customized collaboration of design process based on digital model.The information integration and multi-dimensional monitoring of the whole process of scientific research and production promotes the continuous optimization of business process and the continuous improvement of development efficiency, and supports the transformation and the upgrade of development model for liquid rocket engine.