作者简介:杜宗罡(1971—),男,研究员,研究领域为液体推进剂。

备注

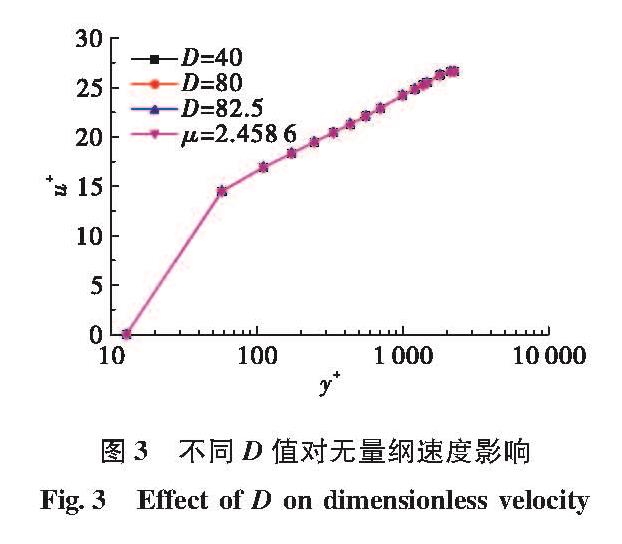

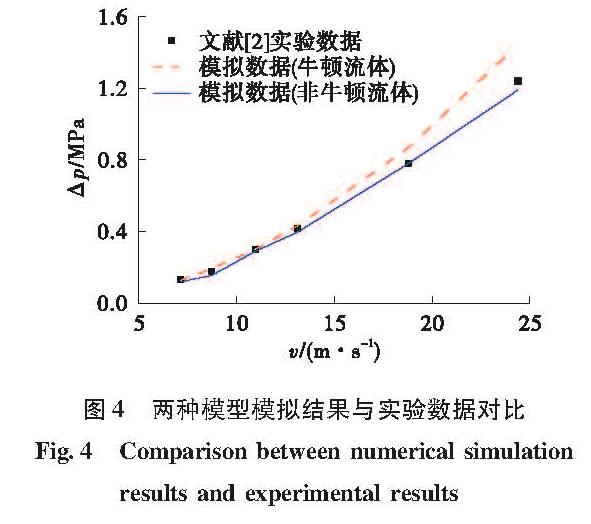

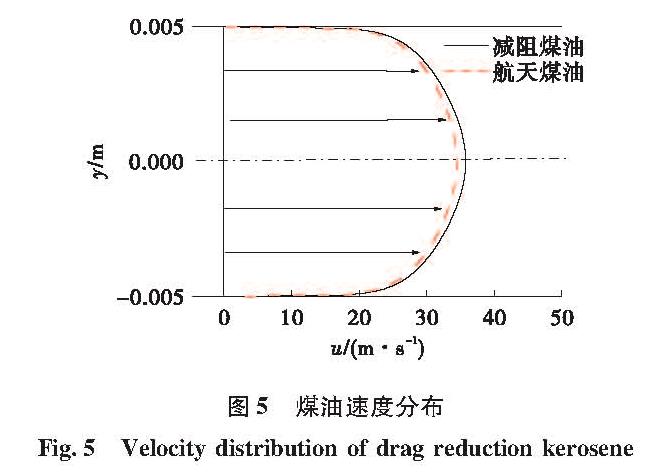

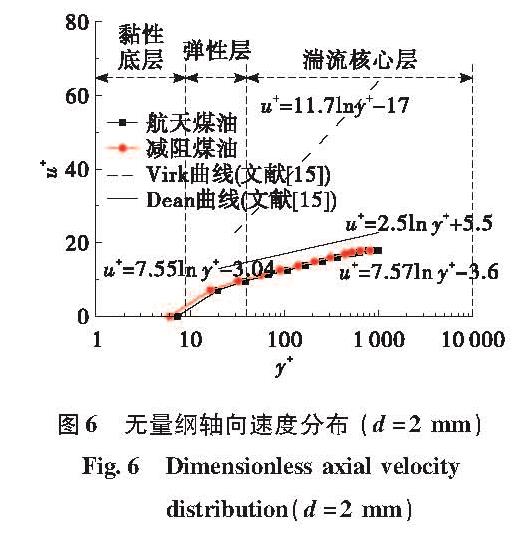

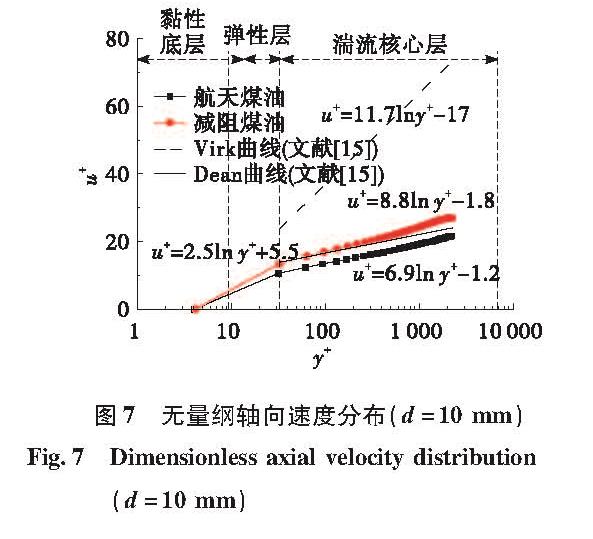

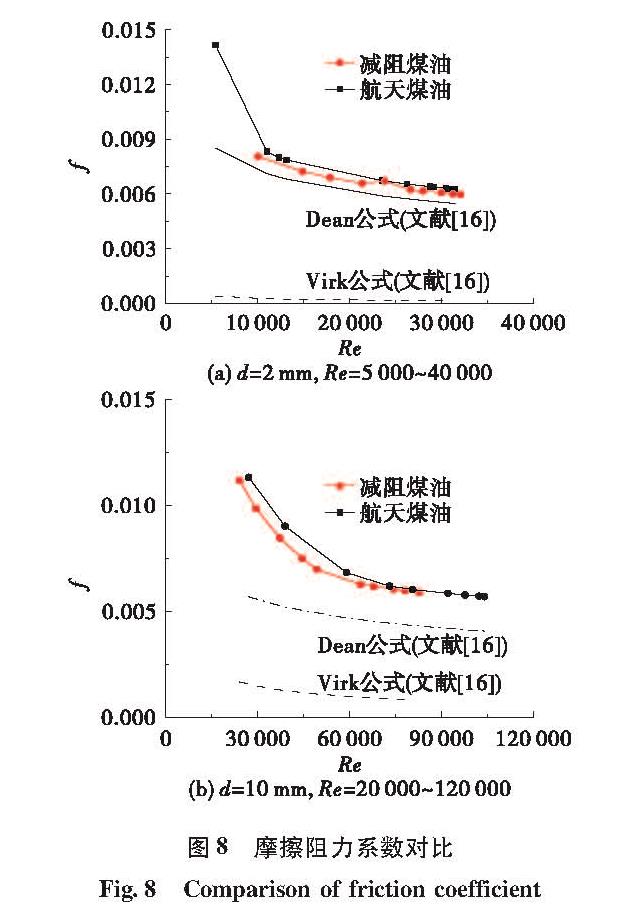

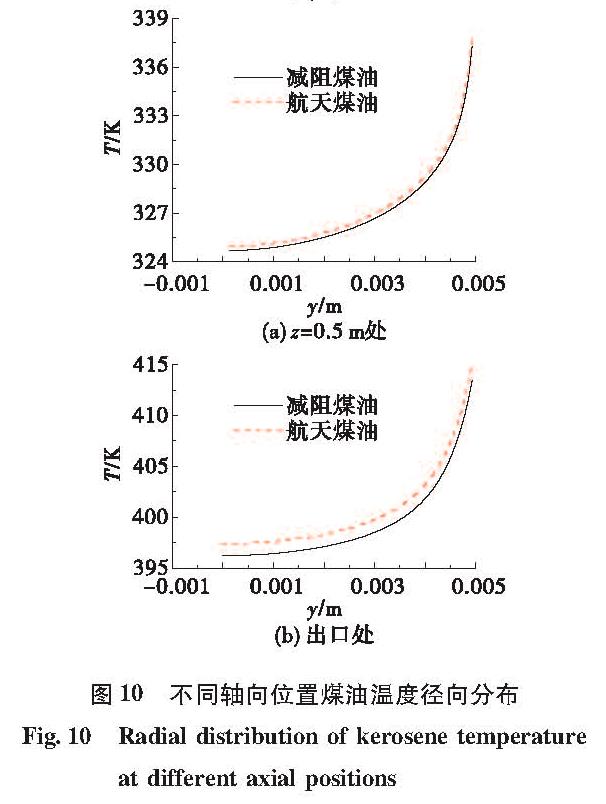

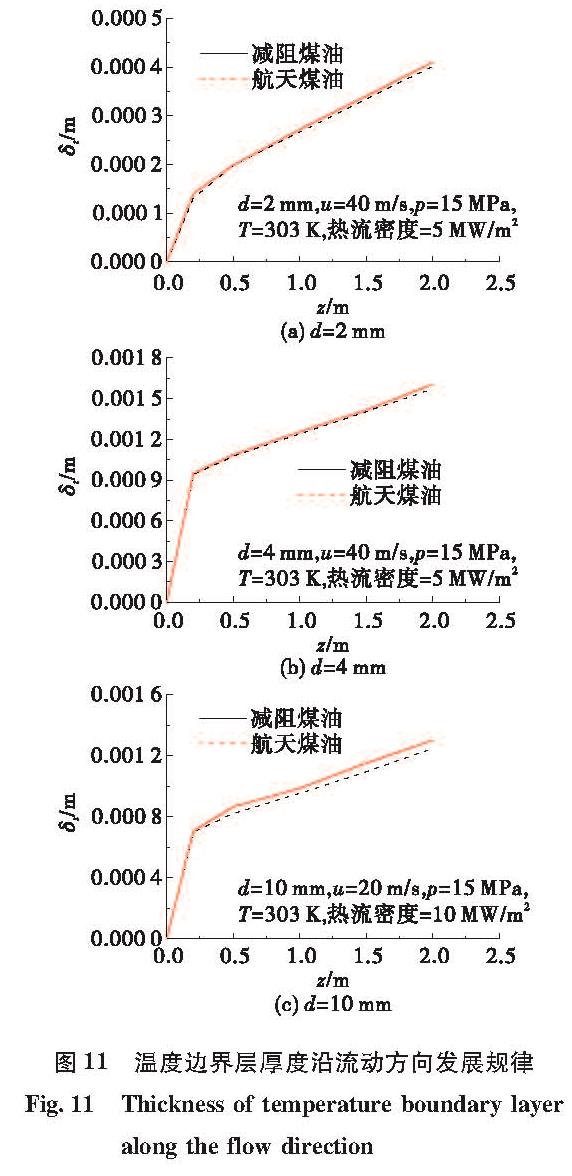

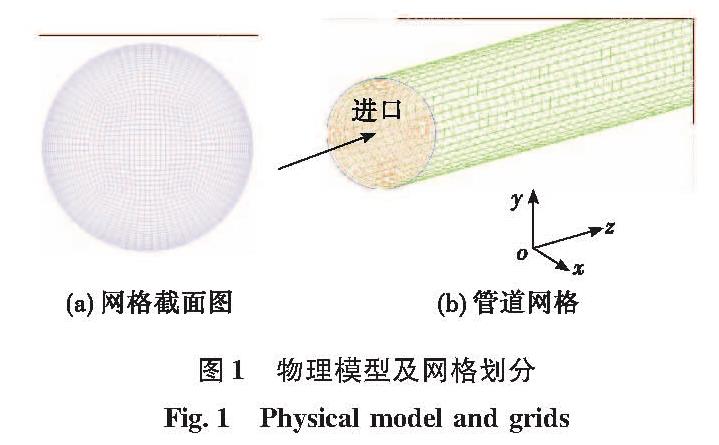

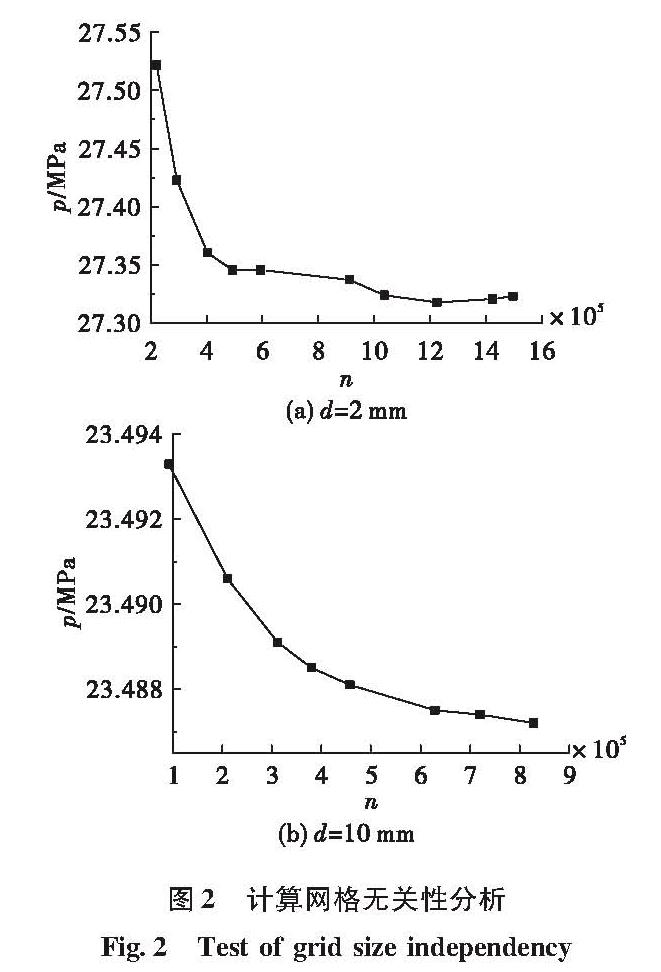

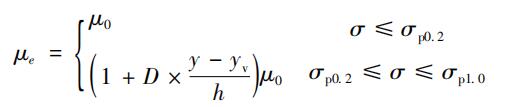

在火箭煤油中添加高聚物进行有效减阻已有大量实验研究,但对于煤油流动与传热过程中流场与温度场的分布及机理分析较少,采用CFD方法对火箭煤油减阻机理与传热规律进行三维数值模拟分析,并与普通煤油进行对比。等效黏度模型采用UDF进行编译,其黏性项分别采用非牛顿流体与牛顿流体模型进行处理。数值模拟研究表明,减阻剂的添加使得减阻煤油流动边界层内的过渡层呈现增厚的趋势,导致弹性底层速度梯度降低和湍流核心区的流速上升,实现了煤油流动的减阻增输,进而达到了减阻效果。减阻煤油的摩擦阻力系数小于普通煤油,黏弹性添加剂在减阻效应中起到了正向作用,是导致减阻煤油具有湍流减阻效应的主要因素。此外,普通煤油传热管内的温升高于减阻煤油,减阻煤油的温度边界层厚度大于普通煤油的温度边界层,增加了减阻煤油管内的传热热阻,进而降低了减阻煤油的传热速率。

There have been a lot of experimental studies on adding polymers to rocket kerosene for effective drag reduction,but there is less analysis of the distribution and mechanism of the flow field and temperature field in the process of kerosene flow and heat transfer. The Computational Fluid Dynamics(CFD)method was used to reduce the resistance of rocket kerosene. The heat transfer law was analyzed by three-dimensional numerical simulation and compared with ordinary kerosene. The equivalent viscosity model was compiled by Universal Disc Format(UDF),and the viscosity term was treated by non-Newtonian fluid model and Newtonian fluid model respectively. The numerical simulation results show that the addition of drag reducer makes the transition layer in the boundary layer of the drag reducing kerosene flow thicken,resulting in the decrease of the velocity gradient in the elastic bottom layer and the increase of the velocity in the turbulent core region,which realizes the drag reducing and transportation increasing of the kerosene flow and achieves the drag reducing effect. The friction coefficient of drag reduction kerosene is less than that of conventional kerosene. Viscoelastic additive plays a positive role in drag reduction effect,which is the main factor leading to turbulent drag reduction effect of kerosene. In addition,the temperature rise of conventional kerosene is higher than that of drag reducing kerosene,and the thickness of temperature boundary layer of drag reducing kerosene is thicker than that of conventional kerosene,which increases the heat transfer resistance of drag reducing kerosene and reduces the heat transfer rate of drag reducing kerosene.

(1)

(1)

(2)

(2)