基金项目:国家科技重大专项(J2019-III-0021-0065)

作者简介:张业雷(1995—),男,硕士,研究领域为强化换热以及换热器设计。

通信作者:王秋旺(1969—),男,博士,教授,研究领域为传热传质与强化。

(1.西安交通大学热流科学与工程教育部重点实验室,陕西西安710049;2.西安航天动力研究所,陕西西安710100)

(1.MOE Key Laboratory of Thermo-Fluid Science and Engineering, Xi'an Jiaotong University,Xi'an 710049, China; 2.Xi'an Aerospace Propulsion Institute, Xi'an 710100, China)

printed circuit heat exchanger; helium heater; thermal design; flow and heat transfer characteristics

0 引言

印刷电路板换热器(printed circuit heat exchanger,PCHE)是一种在金属薄板上通过化学刻蚀方法加工流体通道,并通过扩散焊技术黏合而成的新型微通道换热器[1],具有紧凑度高、换热效率高、耐高温高压、易于模块化等优势[2-3],在核电、太阳能发电、氢能和制冷等领域展现出广阔的应用前景[4-6]。印刷电路板换热器常见的通道结构有直通道、之字型通道、S型通道和翼型通道[7-10],并带有不同形状的通道截面,如半圆形、矩形、梯形和三角形等[10-12]。

国内外对印刷电路板换热器进行了实验和数值模拟的相关研究,其研究背景主要是核反应堆中间换热器[13],超临界二氧化碳布雷顿循环冷却器和回热器[14],以及浮式液化天然气装置中的换热器[15]等,主要探究结构参数对印刷电路板换热器流动传热性能的影响[16-19]以及不同操作条件下工质在印刷电路板换热器中的流动传热特性等[20-22]。此外,也提出了针对不同结构印刷电路板换热器的传热和阻力关联式,这对印刷电路板换热器的研究具有一定的指导意义[23-24]。

印刷电路板换热器在有限空间内可以提供良好的换热能力,对火箭发动机中的换热器是一种很好的选择,但目前公开文献中却鲜有报道。综上所述,本文对印刷电路板换热器用于火箭发动机中的氦加热器进行了研究,采用分段热力设计方法设计出半圆形直通道印刷电路板式氦加热器,并采用流体计算软件FLUENT进行了数值模拟,验证了设计结果的可靠性,对其流动传热特性进行了分析。

氦加热器的设计工况如表1所示,氦加热器的热侧工质为燃气,流量为15 kg/s,入口温度670 K,入口压力为23.6 MPa,流阻要求不大于4 MPa。冷侧工质为氦气,流量为0.5 kg/s,入口温度为110 K,入口压力为3.2 MPa,冷侧出口温度要求为542.6 K,流阻要求不大于2.55 MPa。

相较于传统的换热器设计方法,分段热力设计方法可以减小工质物性变化对温度和传热系数沿程分布的影响,从而减小物性变化在换热器计算过程中引入的误差。根据氦加热器的设计工况,采用分段热力设计方法对印刷电路板式氦加热器进行设计,选用半圆形直通道结构,采用逆流布置的方式,分段热力设计方法的示意图如图1所示。在规定冷侧出口温度的前提下,根据热平衡关系可以求得热侧燃气的出口温度,按照冷侧进出口温度,将氦加热器均分为N段,则得到N+1个节点,求得每一个冷侧节点的温度Tc,i,每一小段存在热平衡关系,可以求得热侧每一个节点的温度Th,i。其中下标h代表热侧,下标c代表冷侧,下标i代表分段序号。

对于每一小段来说,其每一段的换热量Qi满足热平衡关系为

Qi=mh(Hh,i+1-Hh,i)=KiAiΔTm,i(1)

式中:Q为换热量; m为质量流量; H为比焓值; K为传热系数; A为换热面积; ΔTm为对数平均温差。

要选择合适的关联式求每一段的传热系数Ki以及每一段的压降,在计算过程中,以冷热流体进出口平均温度作为定性温度进行物性的计算,物性来源于NIST数据库,通过MATLAB程序进行调用。冷热流体的雷诺数Re计算式为

Re=(ρuDh)/μ=(mDh)/(μAc)(2)

式中:ρ为流体密度; u为流体流速; Dh为通道的水力直径; μ为动力黏度; m为质量流量; Ac为通道的横截面积。

当流体的雷诺数Re<2 300时,流动状态为层流,采用文献[25]提出的关联式计算努塞尔数Nu和达西摩擦系数fd,即

Nu=4.089(3)

fd=4×15.767/Re(4)

当流体的雷诺数Re≥2 300时,流动状态为湍流,采用Gnielinski[26]和Filonenko[27]提出的关联式计算努塞尔数Nu和达西摩擦系数fd,即

Nu=((fd/8)(Re-1 000)Pr)/(1+12.7(fd/8)1/2(Pr2/3-1))(5)

fd=(1.82lg Re-1.64)-2(6)

式中Pr为普朗特数。

通道的阻力损失Δp计算式为

Δp=fdl/(Dh)(u2ρ)/2(7)

式中l为通道长度。

在氦加热器设计过程中,分段数N的不同会导致每一段冷热侧流体的进出口温度不同,其采用定性温度计算的物性也会不同,从而导致采用关联式计算得到的传热系数存在差异,直接对换热器的传热面积以及换热器长度产生显著影响。分段数N越大,每一段冷热流体进出口温差越小,其采用进出口平均温度作为定性温度计算的物性对设计过程引入的误差越小,但分段数的增加同时会带来计算资源的增加。为了确定分段数N,需要进行分段无关性验证,在保证计算准确性的前提下,选择合适的分段数N,减少计算资源的浪费。本文以氦加热器长度l作为判断标准进行分段无关性验证,氦加热器长度l与分段数N的关系如图2所示,可以看出,当分段数N取50以后,换热器长度随分段数增加保持不变,因此分段数N取50以后,换热器长度随分段数增加保持不变,因此分段数50段。

氦加热器的设计结果如表2所示。氦加热器选用半圆形直通道结构,固体材料选择316L不锈钢,采用逆流布置的方式,冷热流体通道单排排列且一一对应。采用分段热力设计方法计算得到的氦加热器芯体总长268.2 mm,体积为0.002 7 m3,质量为12.62 kg。热侧的出口温度为602.3 K,压力损失为1.46 MPa,冷侧的出口温度为546.2 K,压力损失为0.099 MPa,均符合设计要求。

采用FLUENT软件对氦加热器进行数值模拟,由于印刷电路板换热器流道具有周期性分布特点,因此对模型进行简化,选择一组冷热通道作为一个计算单元进行模拟。计算单元的几何模型如图3所示,主体部分长度为268.2 mm,在冷热通道进出口分别设置30 mm的延长段来保证入口的均匀以及防止出口的回流,冷热流体的进出口均设为质量流量入口和压力出口。计算单元的横截面如图4所示,计算单元的宽度为2.8 mm,高度为3.6 mm,上下左右壁面分别为两对周期性边界,前后壁面均为绝热壁面。

采用ICEM对计算单元进行网格划分,整体网格采用结构性网格,对冷热通道近壁面区域的网格进行加密处理,为保证近壁面处的计算精度,将y+值控制在小于1的范围内。

将氦加热器计算单元内冷热流体的流动视为三维不可压缩的稳态流动,其连续性方程、动量方程、能量方程如下。

连续性方程为

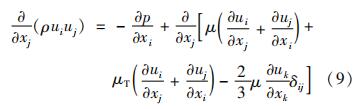

动量方程为

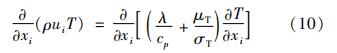

能量方程为

选择SIMPLE算法进行求解,选择SST k-ω湍流模型进行模拟。冷热流体的物性来源于NIST数据库,通过多项式拟合的方式在FLUENT中实现。固体的密度和比热容设置为常数,热导率设置为随温度变化的函数,所有方程均采用二阶迎风格式进行离散,以每个变量的残差小于10-8作为判断收敛的标准。

在数值模拟中,网格的数量和质量对模拟结果的准确性影响巨大,因此在展开数值计算之前需进行网格独立性验证。在计算之前,首先采用了5套不同网格数量的网格进行独立性验证,网格数量分别为79万、155万、233万、269万、317万。模拟工况均采用设计工况,假设冷热流体在所有流道均匀分布,并以热侧温降和压降作为判断标准。网格无关性验证的结果如图5所示,当采用233万网格时,其热侧温降与压降随着网格数的增加,变化不超过0.5,因此选择网格数量233万的网格作为计算网格。

将氦加热器的模拟结果与热力设计结果进行对比,验证本文采用分段热力设计方法的可靠性,氦加热器模拟值与计算值对比如表4所示。从表中可以看出,冷热侧温降的模拟值与计算值之间的相对误差分别为1.33和1.08,冷热侧压降的模拟值与计算值之间的相对误差分别为18.51和7.11,模拟值与计算值整体误差较小,这说明本文采用分段热力设计方法计算得到的印刷电路板式氦加热器是准确可靠的。

以热侧入口作为起点,对氦加热器的传热特性进行分析,冷热流体的沿程温度分布以及沿程温差分布如图6所示。从图中可以看出,冷热流体的温度变化趋势一致,但冷流体的温度变化更为剧烈,这就导致温差随沿程的增大而增大,最大温差出现在氦加热器的冷端,这与逆流换热器的特性是一致的。

图7为氦加热器冷热侧热流密度q的沿程分布。热流密度从氦加热器的热端到冷端呈现增大趋势,这与氦加热器的温差分布相对应。由于换热能力与温差分布紧密相关,温差是进行热交换的驱动力,一般来说,温差越大,热流密度越大,换热能力越强。

图8和图9分别为氦加热器冷热流体努塞尔数Nu和换热系数h的沿程分布。从图中可以看出,冷热侧努塞尔数和换热系数沿程变化不大,但热侧的努塞尔数和换热系数要远大于冷侧。这说明热侧的换热能力要远大于冷侧,与每个通道内热侧的流量远大于冷侧有关,热流体的流速远大于冷流体,其流动更加剧烈导致换热能力更强。

同样以热侧入口作为起点,对氦加热器的流动特性进行分析。图 10为氦加热器冷热流体的雷诺数沿程分布,可以看出,冷热流体的雷诺数变化趋势一致,但冷侧雷诺数变化更为剧烈。这主要是由冷侧氦气物性变化剧烈引起的,热侧的雷诺数远大于冷侧,也是由于每个通道内热侧的流量远大于冷侧引起。

图 11为氦加热器冷热侧范宁摩擦因数f的沿程分布。可以看出,冷侧的沿程范宁摩擦系数大于热侧,且变化更为明显。这与冷热侧雷诺数变化趋势相对应,且主要与冷热侧的物性变化有关。

氦加热器冷热侧压降沿程分布如图 12所示。从氦加热器的热端到冷端,冷热侧压降呈现变小趋势。这主要是由于工质物性变化以及流体速度改变引起,热侧压降远大于冷侧压降,是因为每个通道内热侧的流量远大于冷侧,从而导致了更大压降。

本文针对火箭发动机氦加热器,采用分段热力设计的方法设计了半圆形直通道印刷电路换热器,并采用FLUENT软件对印刷电路板式氦加热器进行了数值模拟,研究了氦加热器的流动换热特性,获得如下结论:

1)通过分段热力设计方法得到的印刷电路板式氦加热器芯体的质量仅为12.26 kg,体积仅为0.002 7 m3。冷热侧温降的模拟值与计算值之间的相对误差分别为1.33和1.08,冷热侧压降的模拟值与计算值之间的相对误差分别为18.51和7.11,模拟值与计算值整体误差较小,说明本文所开发的分段热力设计方法是准确可靠的。

2)对印刷电路板式氦加热器来说,冷端温差最大,换热能力也最强,对冷热流体来说,热侧的换热能力远大于冷侧。

3)氦加热器冷热流体的流动特性与其物性变化紧密相关,冷侧的物性变化更剧烈,所以雷诺数和范宁摩擦系数变化更为明显,但热侧具有更大的流量,也具有更大的雷诺数和压降。