2.1 基本物性的分析

对于低温推进剂的热力学评估,基础热物理性质极其重要。火箭有效载荷、低温推进剂流动、换热等特性均与推进剂密度息息相关。低温推进剂饱和温度与饱和压力等物性直接影响其贮存特性。动力黏度、比热容和导热率是评价低温推进剂流动、贮存和换热等热物理过程的重要指标。动力黏度同运动黏度一起,反映了低温推进剂流动阻力特性; 比热容是物质蓄热能力的评价指标,高比热容对低温推进剂长久贮存具有重要意义,然而在强化换热方面却起到消极作用; 导热率反映流体的换热效果。表2列出了几种典型低温推进剂基础热物理性质[29]。

表2 3种典型低温推进剂的常规热物性数据(标准沸点状态)

Tab.2 Conventional thermal properties data of three typical cryogenic propellants(at normal boiling point states)

由表2数据可以得到一些初步结论:首先,液氧具有高密度、高贮存温度等优点,但是其黏度较大,比热容较低; 液甲烷贮存温度较高,导热系数较大,密度、黏度和比热都比较适中; 而对于液氢来说,它的优缺点鲜明,贮存温度最低,黏度最小,比热最大,导热率最低,但是其密度最低,不到液氧的十分之一。对于低温推进剂的热力学评估,热物性的评价是它的出发点,更多深入评估需要结合具体结构、流动换热形式等进行综合评价。

2.2 动力特性

低温推进剂与常温液体推进剂、固体推进剂等相比较,比冲更高,能量密度更大,推力性能表现优异,能够为深空探测提供足够动力保障。表3为3种典型低温推进剂推力特性参数。由表可见,液氢理论比冲最高,达到了457 s,其密度比冲反而最小,主要是由于液氢密度较小导致。图3为不同型号火箭的比冲与密度分布情况,液氢密度较低,液氢火箭比冲在420~450 s左右,肼类推进剂密度最高,其比冲多为280 s以下。相比而言,液甲烷和煤油推进剂的密度和比冲较为适中。如今深空探测已经成为越来越多国家和组织的追求目标,液氢推进剂的高比冲特性使其在月球探测、火星探测等航天项目中发挥着不可替代的作用。

表3 推进剂推力特性参数

Tab.3 Thrust characteristic parameters for different propellants

图3 不同型号火箭的比冲与密度分布情况

Fig.3 Specific impulse and density distribution of different types of rockets

2.3 传输特性

低温推进剂的传输特性对于火箭发动机的供液、冷却等需求具有重要意义。低温推进剂在管道内流动,受到自身黏性作用以及管路结构等影响,会产生流动阻力。同时受外界漏热影响,低温推进剂在输运过程中温度升高。流动阻力以及流动温升是评价低温推进剂的基本指标。

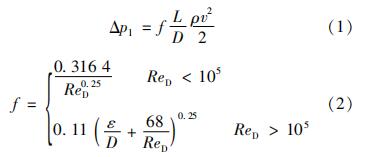

如果低温推进剂具有足够的过冷度,则流动过程中不发生相态变化。这里选定入口状态为常沸点的3种典型低温推进剂进行流动计算,不考虑相变,沿程阻力可按照式(1)进行计算,其中达西阻力系数f需要根据流动雷诺数进行确定,如式(2)所示[30]。

式中:Δpl为液体流动阻力压降,Pa; f为摩擦阻力系数; L为流动距离,m; D为管道内径,m; ρ为液体密度,kg/m3; v为管内平均流动速度,m/s。

取管长为10 m、管道内径为0.1 m、管内壁粗糙度为1 μm的管道作为研究对象。3种典型低温推进剂的流动压降随流速变化规律如图4所示,随着流速的增大,流动压降逐渐增大。而对于3种典型低温推进剂的横向对比可以发现,液氧的流动压降远大于液氢,液甲烷居中。液氢的低黏度和低密度特性是其流动阻力较小的主要原因。

图4 低温推进剂的流动压降随流速的变化曲线

Fig.4 Flow pressure drop curve of cryogenic propellant varies with flow velocity

按此相同条件对低温推进剂在管道内流动温升特性进行研究,基于相同管道参数进行计算。管道内强制对流换系数可按照Dittus-Boelter公式进行确定,如式(3)所示; 出口温度由式(4)确定。

Nu=0.023Re0.8Pr0.4(3)

Tout=Tin+(ShΔT)/(ρvcp)(4)

式中:Nu为努塞尔数; Re为雷诺数; Pr为普朗特数; Tout、Tin为管道进出口液体温度,K; S为换热面积,m2; h为对流换热系数,h=Nuλ/l,W/(m2·K); ΔT为换热温差,K; cp为液体比热容,J/(kg·K)。

传热计算中涉及换热温差的确定,换热温差与推进剂温度和绝热技术有关。换热温差定为2 K。仿真结果如图5所示,随着流动速度的增大,管内换热增强,低温推进剂流动温升也随之增大。此外,对比3种典型低温推进剂的流动温升变化特性,液氢流动温升最大,液氧最小,液甲烷居中。

图5 低温推进剂管道流动温升随流速的变化曲线

Fig.5 Curve of flow temperature rise with flow velocity in cryogenic propellant pipeline

整体看来,液氢流动压降最小,液甲烷次之,液氧最大; 液氧流动温升最小,液甲烷次之,液氢最大。导致这一结果的根本原因在于三者热物性的差异,尤其是密度、黏度、导热系数、比热容等物性。以上仅为简单对比计算就可以发现不同热物理性质对流动特性的影响,实际上,对于低温推进剂流阻特性的综合评价需要更为细致和深入,计算更为复杂。如在预冷过程中,存在低温流体伴随着剧烈沸腾的流动,且随着时间的推进,管路预冷逐步完成,流体沸腾减弱,其两相流动型式由弹状流逐渐转向弥散流、分层流; 不同流体管路的绝热条件不同,漏热对流动的影响会存在明显不同,管壁的边界层效应使得流型发生变化。两相流的出现对流体流动和管路结构强度都会造成重大影响。

2.4 贮存特性

对于推进剂来说,无论是在地面储罐贮存还是空间在轨微重力条件下贮存,都面临环境漏热影响,继而导致低温推进剂的气化损失。在工程实际使用中,针对不同温区低温介质通常采用不同绝热方式,以求在漏热量和成本之间取得相对平衡。现有绝热手段较为丰富,常规聚氨酯发泡材料包裹绝热,珠光砂填充绝热等方式,足以应对100 K左右温区的绝热,高真空多层绝热技术以及低温冷屏技术也可以保证20 K温区液氢的长久贮存。

在假定外界热流密度50 W/m2的前提下,以高5 m、直径3 m的圆柱形贮箱为研究对象,对3种低温推进剂地面停放时温升特性和增压特性进行仿真计算,结果如图6和图7所示。在6 h内,液氧、液甲烷和液氢3种低温推进剂温度分别上升1.93 K、2.54 K和4.83 K,相对增加2.14、2.28和23.72。漏热导致低温推进剂持续蒸发,贮箱压力持续上升,工程实际操作中,一般设定压力到达0.3 MPa时进行泄压操作。当液位为2.5 m时,3种低温推进剂由0.1 MPa增压至0.3 MPa所耗时间分别为36.5 h、 35.3 h和5.5 h。综合看来,液氧在地面停放过程温升最小,增压速率最慢,液甲烷稍弱,液氢温升较大,增压较快,需要注意额外的绝热防护。

图6 贮箱内低温推进剂温度随时间变化(热流密度50 W/m2,贮箱高5 m,直径3 m)

Fig.6 Temperature of low-temperature propellant in the tank varies with time(heat flux of 50 W/m2, height of 5 m, diameter of 3 m)

图7 贮箱内压力随时间变化规律(热流密度50 W/m2,贮箱高5 m,直径3 m)

Fig.7 Pressure in storage box varies with time(heat flux of 50 W/m2, height of 5 m, diameter of 3 m)

受壁面漏热影响,贮箱内部会发生热分层现象。一般采用修正的无量纲瑞利数Ra*来描述箱体热分层强度[12,31]。其表达式如式(5)所示,二者关系如表4所示。

Ra*=((gβqwl4)/(λυ2))((cp,lμ)/λ)(5)

式中:g为重力加速度,9.8 m/s2; β为热扩散系数; qw为外界漏热热流; l为特征尺寸,m; λ为导热系数,W/(m·K); υ为运动黏度,m2/s; μ为动力黏度,Pa·s。

表4 修正瑞利数与热分层的关系

Tab.4 Relationship between the revised Rayleigh number and thermal stratification

可以看出,热扩散系数β、比热容cp和动力黏度μ对热分层的形成起到促进作用,导热系数λ和运动黏度υ则起到抑制作用。另外,贮箱特征尺寸l、外界漏热热流qw都对贮箱内低温推进剂热分层产生促进作用。对特定工况下3种典型低温推进剂的修正Ra随着外界漏热热流的变化规律进行仿真,结果如图8所示。在相同热流条件下,液氢的瑞利数最高,液氧次之,液甲烷最低; 随着热流密度的增大,3种低温推进剂先后由层流进入湍流,其中转变时液氢对应的热流密度约为5 W/m2,液氧约为7 W/m2,液甲烷约14 W/m2。总体来说液甲烷热分层程度最低。

图8 低温推进剂的瑞利数随热流变化曲线(特征尺寸为2.5 m,标准沸点状态)

Fig.8 Rayleigh number curve with heat flow of cryogenic propellant at normal boiling point states with characteristic size of 2.5 m

贮箱内低温流体自然对流时的温度场和速度场分布,以及流体焓值变化是贮存过程中的主要热力学性能表现。但是在实际工程中还需要考虑其他方面,如燃料加注进入贮箱冲击时和贮箱内燃料自然对流与壁面摩擦时所产生的静电积聚现象,低温推进剂与贮箱壁面材料相容性问题,液氢正、仲转化问题等。

2.5 致密化特性

通过增大推进剂密度,使得在现有贮存容积内推进剂装载量增加,火箭干质比提升的技术称为低温推进剂的致密化。目前常用的致密化手段是通过改变现有低温推进剂贮存状态,由标准沸点状态进行降温过冷,从而实现低温推进剂密度的提升; 更有研究尝试制备固、液混合相推进剂,即浆态低温推进剂。

采用过冷实现低温推进剂致密化,有着鲜明优点。流体温度降低,密度随之升高,其饱和压力也随之降低,这有利于降低对火箭贮箱及管路结构的强度要求。但是流体黏度随之增大、比热容减小,这对于低温推进剂的流动和蓄热是不利的。将3种低温推进剂在标准沸点状态和三相点状态的热物性进行对比,如表5所示[29]。分析可知,过冷液氧密度提升潜力最大,为14.15,液甲烷最小,为6.89; 3种低温推进剂在三相点处饱和压力较标准沸点处都有极大降低,液氧下降比例最大,为-99.86; 过冷操作会使得液氧动力黏度增大3倍左右,对流动极其不利,而液甲烷和液氢推进剂的动力黏度增幅也达到了65和89。此外,液氧和液甲烷比热容稍有下降,在5以内,对其蓄热表现影响较小,然而液氢的降幅达到28,在实际操作中不可忽略。同时过冷致密化使得低温推进剂的热物理性质发生改变,从而使得低温推进剂的动力特性、传输特性和贮存特性都发生改变。

表5 过冷低温推进剂热物理性质

Tab.5 Thermophysical properties of subcooled cryogenic propellants

过冷致密化技术本身并不能改变推进剂的燃烧特性,其对推进剂动力特性的影响主要体现在密度提升。过冷后低温推进剂组合的混合密度相对提升反映了火箭载荷的相对提升,载荷相对提升量随燃料过冷温度的变化规律如图9中黑色曲线所示,当液氢和液甲烷从标准沸点过冷至三相点,其载荷相对增加8.66和6.89。需要指出的是,在推进剂组合混合比以及火箭贮箱结构确定的情况下,火箭燃料与氧化剂的密度在过冷过程中需要保持一个定值,以避免其中一者有剩余。因此液氢与液甲烷从标准沸点过冷至三相点的过程对应了确定的液氧过冷过程,如图9中红色曲线所示。当液氢、液甲烷过冷至三相点时,液氧需要分别过冷到69.33 K和73.73 K。这表明火箭载荷能力仍有提升空间,可以通过改变贮箱结构,在满足最佳混合比的前提下,使液氧和燃料同时达到最合适的过冷状态。此时,液氢/液氧推进剂组合和液甲烷/液氧推进剂组合相对载荷提升至8.75和7.75。

图9 低温推进剂组合密度比冲随温度变化曲线[当量温度T*=(T-TTP)/(TNBP-TTP)]

Fig.9 Density specific impulse curve with temperature for low-temperature propellant combination [equivalent temperature T*=(T- T TP)/( T NBP- T TP)]

过冷致密化对推进剂传输特性影响如图 10所示。3种推进剂流阻压降均有所提升,液氧增幅最大,液甲烷次之,液氢最小; 三者在流速为10 m/s时的相对增幅分别为41.36、15.42和18.64。可见过冷对液氧的传输特性影响最大,加之液氧在标准沸点状态下传输特性在三者当中表现最差,因此在对液氧进行过冷输运时需要注意调整输送压力。

图 10 过冷致密化对推进剂传输特性的影响

Fig.10 Effect of subcooling densification on propellant transport characteristics

过冷致密化能够为低温推进剂提供额外的显冷量,有效增加其贮存周期。图 11反映了过冷低温推进剂从地面停放阶段到贮箱泄压阶段的贮存周期时长对比。低温推进剂由过冷状态达到标准沸点状态的过程称为过冷升温阶段; 从标准沸点状态达到贮箱泄压的过程称为气化增压阶段。由图可知,液氧、液甲烷和液氢的过冷升温阶段分别为117 h、125.2 h和36.5 h。整个贮存周期相对提升322.82、354.67和285.45,可见过冷对提升低温推进剂的贮存特性极为有利。

图 11 过冷液氧贮存温度和压力随时间变化规律

Fig.11 Variation of storage temperature and pressure of supercooled liquid oxygen with time