基金项目:中国航天科技集团有限公司自主研发项目; 国家重点实验室基金项目(HTKJ2021KL011003)

作者简介:姜薇(1987—),女,博士,研究领域为发动机结构强度及寿命。

National Key Laboratory of Aerospace Liquid Propulsion, Xi'an 710100, China

liquid rocket engine; metallic seal; reusability; compression springback property

DOI: 10.3969/j.issn.1672-9374.2024.01.010

金属密封结构广泛用于液体火箭发动机低温推进剂供应系统及高温燃气通道,通常采用硬质合金作为基体,表面镀覆铜、银等软金属层,具有结构简易、质量轻、位移补偿性能好及工作载荷下自紧等优点,能够适应高(低)温、高压及强腐蚀等恶劣环境[1-5]。发动机常见的金属密封环结构形式包括U-E环、自定位K形环、横向K形环、V形环等,其中U-E密封作为自紧式双道密封,主要用于大通径高温高压燃气通道,工作环境严苛,泄漏失效最为频繁。针对U-E密封的研究较少,马莹等利用有限元模型对U-E密封进行了建模分析,研究了主副密封唇的压缩量与密封环等效应力、塑性应变及接触压力之间的关系[6]。王晨威等将法兰服役条件下的变形量引入U-E密封环的设计,开展正交试验对主副密封高度进行了匹配优化设计[7]。核电反应堆压力容器中常采用金属O形密封环或C形密封环[8-10]。姜露等对金属C形密封环建立精细化分析模型,对密封环的压缩回弹特性曲线进行精确模拟,并通过实验验证了数值分析方法的正确性[8]。张文昌等分析了金属O形密封环的压缩回弹性能、接触性能和镀层的影响,发现压缩率决定密封的回弹补偿性能,镀层增加了接触面积、均匀化了接触压力分布,对回弹特性影响可以忽略[11]。Shen等分析了金属O形密封环几何参数和压缩率对密封性能的影响,发现压缩率对密封环接触应力的分布和大小有重要的影响[12]。Sarawate等通过高温试验台开展了多种W型金属密封环的密封特性试验,得到了W型金属密封环在不同压缩量下的密封性能[13] 。

液体火箭发动机金属U-E密封在重复使用过程中,主副密封悬臂根部经历循环塑性应变的作用,由于工作载荷具有非对称性,局部会在平均应力方向出现塑性应变循环累积,产生棘轮效应。基体合金的循环应力-应变行为和棘轮应变累积会显著影响密封环的压缩回弹性能,棘轮损伤累积也会缩短密封环的疲劳寿命。金属密封结构的密封性能主要取决于自身的压缩回弹特性和接触特性,其中压缩回弹性能决定了密封环的补偿能力,只有密封环的补偿量大于法兰接头在工作载荷作用下产生的变形分离,密封环才能通过接触作用提供一定的密封比压,从而达到密封介质的作用。已有的密封压缩回弹研究主要针对密封圈线弹性范围服役情形,没有考虑重复使用过程中局部进入塑性变形对压缩回弹性能的影响,忽略了高温密封在反复压缩回弹过程中的棘轮和疲劳的交互作用。

金属U-E密封结构通常采用镍基高温合金,工作在高温环境下其塑性力学行为与常温情况下不同,具有明显的黏性特征,加载速率、环境温度、载荷保持时间等因素会显著影响材料的变形情况,进而影响密封环在重复使用过程中的压缩回弹行为。金属密封结构在重复使用过程中存在局部严重塑性变形区域且承受非对称循环载荷,材料的循环应力-应变关系表现为复杂的硬化、软化和棘轮现象,需要建立具有混合(等向-随动)应变强化模型的循环黏塑性本构对其力学行为进行描述[14-15]。自20世纪80年代以来,学者们针对棘轮塑性本构模型开展了大量的试验及理论研究,基于试验获得的棘轮应变演化规律建立了多种宏观唯象的循环塑性本构模型[16-22]。本文基于镍基高温合金的循环力学行为试验,确定了Chaboche循环黏塑性本构模型参数,对金属U-E密封结构在循环使用载荷作用下的力学行为进行了仿真分析,研究了金属密封结构重复使用性能演化规律。

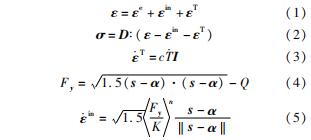

本构关系是材料在特定温度和载荷环境中的应力-应变关系,是对材料力学响应的直观数学描述。黏塑性本构是一种与时间相关的本构,反映了塑性和黏性的共同作用。在统一黏塑性理论中将塑性变形和黏性变形统一处理为非弹性变形,用流动法则来反映与时间相关的塑性变形的演化过程[23]。建立循环黏塑性本构通常包含以下基本要素:应变分解、屈服函数、流动法则和硬化模型。在小变形加分解、初始各向同性弹性及关联性流动法则条件下,循环黏塑性本构模型的主控方程为

式中:ε、εe、εin、εT分别为总应变张量、弹性应变张量、黏塑性应变张量及温度应变张量; σ为应力张量; D为四阶弹性张量; “:”表示二阶张量间的内积; ε·in和ε·T分别为黏塑性应变率张量和热应变率张量; c为线膨胀系数; T·为温度变化率; I为二阶单位矩阵; s和α分别为偏应力和背应力张量; K和n均为反映率相关性的材料常数; Q为各向同性变形抗力; “  ”为McCauley运算符,其含义为当x≤0时,〈x〉=0,当x>0时,〈x〉=x; Fy为J2屈服函数,在统一黏塑性本构理论中,只有当其值大于0时才会有新的黏塑性变形产生。

”为McCauley运算符,其含义为当x≤0时,〈x〉=0,当x>0时,〈x〉=x; Fy为J2屈服函数,在统一黏塑性本构理论中,只有当其值大于0时才会有新的黏塑性变形产生。

为了准确描述材料在循环载荷作用下的软硬化、平均应力松弛和棘轮等循环特性,本构模型的发展主要集中在提出更好的随动硬化和各向同性硬化律上。线性随动硬化模型不能合理地描述材料的棘轮行为,因此在循环棘轮本构模型中通常采用非线性随动硬化模型。非线性随动硬化模型大多是基于Armstrong-Frederick(A-F)[24-25]动态恢复模型改进发展的,A-F模型包含一个线性强化项和一个动态恢复项,由于动态恢复项的存在会引起随动硬化准则的非线性,导致一个不闭合的滞回环,从而可以模拟材料的棘轮行为。Chaboche模型在A-F模型的基础上将背应力分解为若干项,并且令每一项服从A-F随动硬化模型,每一项背应力分量反映材料在不同塑性变形阶段的非线性行为,即

式中:Ci和γi为材料常数;  为累积塑性应变率。

为累积塑性应变率。

一般来说,一个稳定的应力应变滞回曲线可以分为3个重要阶段:刚开始屈服时的高塑性模量阶段、恒定的塑性模量阶段(应变范围较大时)和拐角处的瞬时非线性阶段。Chaboche模型分别用3个背应力分量来描述这3个阶段,能够较好地模拟滞回曲线。

建立循环黏塑性本构时,通常同时考虑随动硬化和各向同性硬化作用来描述材料的循环软化/硬化行为及其对棘轮损伤的影响。各向同性硬化表示在应力空间中屈服面向各个方向等量扩大,应力在塑性流动中逐渐变化。本文采用了如下非线性形式的各向同性硬化模型。

Q·=b(Qsa-Q)p· (8)

对式(8)积分可得

Q=Qsa(1-e-bp) (9)

式中:Q为各向同性变形抗力,反映了屈服面半径在变形过程中的变化情况; Qsa为饱和各向同性变形抗力; b为材料参数,描述Q的演化速率。

棘轮变形是叠加在材料基本循环应力-应变响应上的二次变形,随循环周次的增加逐渐累积,超过材料的断裂应变后,最终导致材料“延性耗尽”进而断裂失效。为了更好地揭示非对称应力循环载荷下棘轮效应,本文使用如下的棘轮应变定义分析循环变形过程中棘轮应变值随循环周次的变化。

εr=(εmax+εmin)/2 (10)

式中εmax和εmin分别为每个循环中的最大应变值和最小应变值。

U-E密封由变厚度的两对主、副密封唇,限位台等组成,结构如图1所示。主密封唇构成第一道密封,副密封唇构成第二道密封,两道密封之间设置限位台,避免主、副密封唇受到过量压缩。装配时,上、下法兰通过螺栓预紧力作用压紧主副密封唇,产生初始比压; 工作中,法兰受到压力和温度的作用,上下法兰产生变形分离,同时高温介质填充至主密封上下悬臂内侧,主密封张开回弹产生自紧,比压增大; 当第一道密封发生泄漏时,第二道密封前腔体压力上升,副密封产生自紧,比压增大,最终实现双道自紧密封。

密封环的压缩回弹分析中需要对密封环和法兰的变形情况进行表征,主要涉及密封环自身的压缩量、回弹量及法兰的分离量。压缩量是密封环在装配过程中一对主(或一对副)密封唇沿轴向相对运动的位移,为密封环的重要设计变量; 由上、下法兰之间的初始装配间隙控制,通常预紧力小部分先由密封环直接承受(使U-E密封环压缩至设计压缩量),后续大部分预紧力由法兰承受。回弹量是密封环自身性能,由密封环的结构形式和材料性能决定; 密封环被加载至一定压缩量过程中主副密封悬臂根部会产生一定量的塑性变形,使密封环卸载后不能回弹至初始位置,而回弹量定义为压缩量与卸载后密封环剩余压缩量之差。法兰分离量是其在工作载荷下的变形状态,一般会在法兰外边沿、主密封唇和副密封唇所在径向位置进行测量,法兰受到高温及介质压力的作用后,相对于初始装配压紧状态会相互分离,主、副密封唇位置的分离量分别小于各自的回弹量是可靠密封的前提。

金属密封法兰结构工作过程中受到螺栓预紧力、介质压力及高温的循环作用,如图2所示。图2所示的高温燃气通道密封法兰连接结构中,螺栓规格为M22,装配预紧力为180 kN,额定工作内压为28 MPa,最高工作温度为500 ℃。

目前金属密封法兰结构典型的循环使用过程为一次装配、多次热试车之后拆卸,在每一次热试车过程中密封环会经历加压/升温和泄压/降温过程,考虑到升压和卸压过程是瞬间完成的,而升温和降温过程相对要缓慢得多,因此本文分析的典型循环使用过程为:常温预紧→(加压→升温→卸压→降温)×8→拆卸。

为了分析螺栓预紧力及介质压力对金属密封循环使用力学行为的影响,计算中考虑了3组载荷工况。①工况1:预紧力180 kN,介质压力28 MPa。②工况2:预紧力130 kN,介质压力28 MPa。③工况3:预紧力180 kN,介质压力33.6 MPa。

密封环的基质材料为镍基高温合金,表面镀覆纯铜,镀层的名义厚度仅几十微米,不影响密封环的承载能力,对密封环进行循环压缩回弹分析时,可以不考虑铜镀层的影响。法兰在循环使用过程中整体处于纯弹性,局部会发生微量屈服,可采用具有双线性等向强化法则的弹塑性本构模拟法兰。

弹塑性分析中材料的应力-应变关系通常需要借助于真应力σT和真应变εT来描述,而真应力和真应变是基于试样当前构形计算得到的,在达到颈缩之前与工程应力σN和工程应变εN具有如下关系。

σT=σN(1+εN) (11)

εT=ln(1+εN) (12)

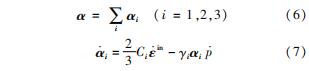

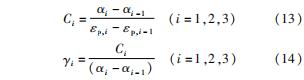

材料的杨氏模量E、泊松比ν、初始屈服强度Q0及塑性模量Ep可以通过单轴拉伸试验获得的应力-应变曲线直接确定。采用统一黏塑性循环本构模型对金属密封在重复使用过程中的力学行为进行模拟时,还需要用到黏性常数、随动硬化参数和各向同性硬化参数,可以通过单轴拉伸及循环加载试验结果进行确定,具体方法如下。

1)黏性常数K和n由不同应变率下单调加载的单轴拉伸应力-应变曲线确定。

2)由于Chaboche模型采用3个背应力分量来反映材料不同塑性变形阶段的非线性行为,可以根据单轴拉伸曲线绘制背应力随塑性变化曲线,然后计算背应力参数Ci和γi,计算式为

3)各向同性硬化准则中与后继屈服应力演化规律相关的参数Qsa和b,需结合应变循环下的应力幅值随塑性应变变化曲线获得。

表1列出了依据试验结果确定的密封环材料的Chaboche模型参数,表2列出了计算中使用的法兰材料性能参数。

采用Chaboche循环黏塑性本构和2.3节所确定的模型参数对U-E密封环在循环力热载荷作用下的力学行为进行了数值分析。图3和图4分别为3种载荷工况下副密封和主密封唇轴向接触合力随循环使用历程的变化情况,实线均为上密封唇轴向接触合力,虚线均为下密封唇轴向接触合力。图5和图6分别为3种载荷工况下副密封和主密封悬臂根部径向应力-应变迟滞回线。图7和图8分别为3种载荷工况下副密封和主密封悬臂根部局部塑性应变随循环使用历程的累积情况。图3~图8中横坐标均为有限元分析中的分析步,每一个分析步用于实现一组载荷的施加,反映了法兰密封结构的加载历程,分析步1用于模拟法兰的装配预紧过程,分析步2~5分别用于模拟第一次工作循环过程的加压、升温、泄压和降温过程,分析步6~9用于模拟第二次工作循环过程,依次类推。

由图7和图8可以看出:初始装配过程中,相同压缩量下副密封悬臂根部产生了更高的塑性应变,达到了3.2%,而主密封悬臂根部塑性应变仅达到0.5%,其主要原因为副密封唇沿径向更接近螺栓分布圆(见图2),相较于主密封传递了更高的轴向压缩载荷(见图3和图4,副密封唇轴向接触合力为85 kN,主密封唇轴向接触合力为76 kN),同时副密封的悬臂刚度亦显著低于主密封。

循环使用过程中,介质压力会作用至主密封悬臂内侧产生自紧作用,从而使主密封和副密封的循环力学行为表现出完全不同的特点。加压过程中,主密封唇轴向接触合力由于自紧作用继续上升; 而对于副密封,介质压力使上下法兰发生分离,抵消一部分压紧作用,从而使副密封唇轴向接触合力相对于装配状态有所下降。升温过程中,由于螺栓受热伸长,作用于上下法兰的压紧力下降,同时高温导致法兰和螺栓材料性能下降,法兰进一步变形分离,使主副密封唇传递的轴向合力均出现下降。泄压后,主密封悬臂内侧压力卸除,自紧作用消失,使主密封唇轴向接触合力显著下降; 而对于副密封,由于介质压力产生的法兰分离消失,副密封唇轴向接触合力回升。降温后,螺栓热膨胀恢复,由于螺栓伸长引起的法兰分离消失,主副密封唇传递的轴向合力均出现上升。经历第一次加压→升温→卸压→降温循环载荷后,主副密封轴向接触合力均恢复到接近预紧状态水平,但在经历了多次循环使用后,副密封唇的轴向接触合力明显发生了下降,而主密封唇的几乎未发生明显衰减。其原因可以依据图5~图8给出的主副密封悬臂根部循环应力应变行为进行分析。

图5 副密封悬臂根部危险部位径向应力-应变滞回曲线

Fig.5 Radial stress-strain hysteresis curve at the critical site in cantilever root of secondary seal

图6 主密封悬臂根部危险部位径向应力-应变滞回曲线

Fig.6 Radial stress-strain hysteresis curve at the critical site in cantilever root of main seal

图7 副密封悬臂根部局部塑性应变随循环加载历程的累积

Fig.7 Local plastic strain of the critical site in the secondary seal during cyclic loading procedure

图8 主密封悬臂根部局部塑性应变随循环加载历程的累积

Fig.8 Local plastic strain of the critical site in the main seal during cyclic loading procedure

图5和图6中,主副密封悬臂根部局部屈服部位在非对称循环载荷作用下均出现了非闭合应力-应变迟滞环,随着循环使用次数增加副密封迟滞环向前移动得更加明显,即附加了更大的棘轮应变。相应地,在图7和图8中,副密封悬臂根部等效塑性应变在棘轮效应的影响下,累积速度明显快于主密封。循环使用8次并卸除螺栓预紧力后,3种载荷工况作用下副密封悬臂根部残余的等效塑性应变分别达到了4.6%、4.9%和5.0%,而主密封悬臂根部残余的等效塑性应变仅为0.5%、0.6%和0.7%,较高的残余塑性应变水平使副密封回弹能力下降,表现为副密封唇轴向接触合力下降。另一方面,累积塑性应变水平(PEEQ)一定程度上反映了密封环所经历的损伤量,经过8次循环使用后,3种载荷工况作用下副密封悬臂根部的累积塑性应变分别达到了6.2%、7.2%和7.6%,主密封悬臂根部的累积塑性应变分别为0.9%、1.4%和2.7%,从而可以推断相较于主密封,副密封更易发生疲劳破坏。对比3种载荷工况下密封环的循环应力-应变行为,较高的介质压力和预紧力不足均会导致塑性应变的加速累积,进而影响密封环的循环压缩回弹性能和疲劳寿命。

基于统一黏塑性理论,采用Chaboche 非线性随动硬化和饱和型各向同性硬化模型共同描述密封环基体材料循环力学行为,分析了密封环经历8次循环使用过程中主副密封唇宏观接触合力的演化规律和局部塑性应变累积部位的损伤进程,得到了以下结论。

1)工作中介质压力会作用至主密封悬臂内侧并产生自紧作用,使主密封和副密封在循环使用过程中轴向接触合力表现出完全不同的循环特征,主密封在施加介质压力后接触合力达到峰值,而密封在压紧状态中即达到峰值,主密封受到轴向接触合力水平明显高于副密封。

2)副密封由于刚度低于主密封,其悬臂根部受到了更高的塑性应变,循环使用过程中表现出明显的棘轮效应。经历8次循环使用载荷作用后,副密封悬臂根部残余了更高的塑性应变,导致其回弹能力明显下降,累积塑性应变远高于主密封,预示着更低的疲劳寿命。因而,副密封会先于主密封失效,在重复使用过程不能发挥冗余设计作用。

3)提高的介质压力和预紧力不足均会导致塑性应变的加速累积,进而影响密封环的循环压缩回弹性能和疲劳寿命,应在装配过程中注意控制预紧力。