基金项目:集团科技创新自主研发项目

作者简介:梁文栋(1994—),男,博士,工程师,研究领域为低温介质空化流体动力特性与机理、液体火箭发动机设计仿真。

Beijing Aerospace Propulsion Institute, Beijing 100076, China

regulating valve; liquid oxygen; cavitation model; thermodynamic effect

DOI: 10.3969/j.issn.1672-9374.2024.02.010

阀门作为液体火箭发动机的重要控制组件,其功能是供给或切断推进剂组元流量、维持其出口给定的压力、按要求改变推进剂的流量[1-3]。调节型阀门在调节流量过程中,空泡常在阀芯周围的近壁面溃灭,造成阀芯的剥蚀和振动,严重时会导致阀门调节失效[4-6]。在过去几十年,人们对阀门空化现象的研究通常采用常温水作为研究对象[7-8]。随着航天发射领域的需求不断增加,流体机械的工质已不再局限于常温水[9-10]。液氢、液氧和甲烷等低温介质作为液体火箭发动机的工质在航天领域得到了越来越广泛的应用[11-12]。由于低温介质独特的物质属性,其空化的形态和特征与常温水空化存在很大差异,并伴随强烈的热力学效应[13-14]。

早在1961年,Sarosdy等[15]就在实验中观察到了不同流体介质空穴形态的差异,发现与汽液边界清晰呈透明状的常温水空穴相比,氟利昂的空穴更加模糊并且呈现泡沫状。2019年,北京理工大学Chen等[16]搭建了可进行大范围温度和压力调控的低温介质非定常空化流动测试平台,实现了低温介质空化流动的观测和空穴内部的压力测量。在数值计算方面,空化模型对空化流动的数值仿真有着至关重要的作用。1917年,Rayleigh[17]提出了在不可压缩流体中球形空泡溃灭的控制方程。Plesset[18]提出了著名的Rayleigh-Plesset方程,形成了空泡动力学理论基础。Kubota等[19]根据Rayleigh-Plesset方程最早提出了计算相间传质率的空化模型。由于热力学效应的显著影响,基于常温水建立的传统空化模型已不再能准确预测低温介质空化相变中的相间传质过程。2023年,北京理工大学Chen等[20]提出了一种考虑汽液相间对流换热的热力学修正模型,指出该模型仿真结果与试验结果吻合较好。

随着CFD仿真技术的不断发展,调节阀内部空化流动特性的研究在最近20年得到了越来越多学者的关注。2007年,北京理工大学的李哲等[21]对压力调节阀内部流场进行了动态模拟计算,用动网格模拟阀芯运动,获得了阀门动态特性的影响因素和流场周期性演化规律。台湾科技大学的Chern等[22]针对调节阀开展了可视化试验研究,发现对于调节阀而言,开度越小,流场结构越复杂,越容易发生空化现象。随着低温介质在航天领域的广泛应用,最近几年针对超低温阀门内低温介质空化流动特性的研究正在逐步增加。2021年,Lin等[23]数值研究了球阀开闭过程中液化天然气的空化流动特性,研究表明阀门开度低于20°时,液化天然气空化区域压降最大,随着开度增加,空化区域压降显著降低。2022年,Zhou等[24]采用数值方法模拟了二维截止阀内部的液氮空化流动,发现液氮空穴主要分布在阀腔和阀门下游底部; 在相同工况下,随着截止阀开度的增加,空穴体积分数显著下降,空穴位置从阀腔向侧挡板移动。2023年,李永喜[25]等采用Zwart空化模型对LNG超低温球阀内部的液化天然气(100 K)空化流动进行了数值仿真研究,发现空化现象主要位于结构发生突变的地方,比如焊接法兰位置、阀座附近和球体附近等。

综上所述,目前阀门低温空化流动研究将常温水更换为低温介质后,在数值模型和分析方法上没有反映出热力学效应特征,尤其是热力学效应强度会随低温介质的温度变化而变化。并且对于液体火箭相关领域的阀门低温空化流动研究更少。某型火箭发动机调节阀在液流试验中常常观察到显著的空化现象,空化的产生、发展和溃灭均会对阀芯产生作用力,造成液动力矩和流量特性测量不准确。为了获得调节球阀空化流动的临界工况,分析调节球阀实际运行时的低温流场分布特征,本文采用数值仿真的方法对某型调节球阀常温水和液氧的空化流动及流场分布特性进行了研究。

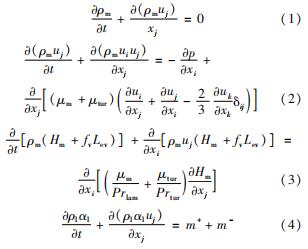

本文研究的球型调节阀在发动机运行时流过液氧介质[9],在液流试验中流过常温水,因此本文分别模拟了发动机运行工况压差下液氧和液流试验工况下常温水的三维不可压两相稳态流动。常温水模拟结果用来和液流试验数据对比。笛卡尔坐标系下的连续方程、动量方程、焓和质量输运方程分别为

式中:u、p、 f、 α、 Lev和H分别为速度、压力、质量分数、体积分数、潜热和焓; ρm为混合物密度; μm和μtur分别为混合物的层流黏性系数和湍流黏性系数; δij为克罗内克函数; Prtur和Prlam分别为湍流普朗特数和层流普朗特数; 下标i、j、k代表笛卡尔坐标系的方向; 源项m+和m-表示凝结率和蒸发率。

本文选取标准k-ε湍流模型,该模型应用多,计算量适中,有较多数据积累和比较高的精度。

相变过程中考虑传热对空泡生长过程影响的修正空化模型为[20]

式中: Fvap和Fcond分别为蒸发和凝结项常数; αnuc为成核点位的体积分数; Hb表征汽液间的对流换热系数; RB为空泡直径; T∞为来流温度; pv(T)为对应来流温度下的饱和蒸汽压; p为液体压强。

本文研究的球型调节阀计算域如图1所示,进出口分别延长5倍管道直径以确保流动充分发展。中间为阀芯区域,右侧为阀芯沿着x轴逆时针旋转80°的位置,为额定工况下的实际开度。计算域表面为无滑移壁面边界条件,进出口面的压差和流量与试验工况及实际发动机运行工况保持一致。

采用ICEM CFD对图1所示的三维流域进行网格划分,进出口圆柱流道采用六面体网格,几何结构比较复杂的中间阀芯区域采用四面体网格,网格特征尺寸为0.8 mm,总网格数为400万。本文首先计算单相定常流动过程,并将单相结果作为初值计算两相定常空化流动过程,设置RMS残差为10-4。

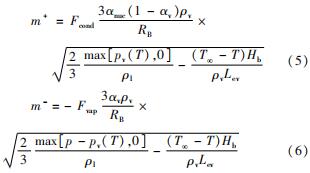

工况参数如表1所示,本文针对不同压差下常温水和液氧的空化流动特性开展数值仿真研究。95 K和100 K的液氧工况对比用来探究温度对流场分布的影响。图2给出了数值仿真计算得到的阀门流通面积与文献[26]中实验数据对比。工程应用中通常采用流通面积μF来表征调节阀的流量系数,如图2虚线所示,在固定开度下,试验测得阀门流通面积为定值,与介质和工况等参数无关。数值仿真结果的阀门流通面积μF通过流量Q、压差Δp、密度ρ等计算获得,即

图2 不同工况数值仿真获得流量系数与试验结果对比

Fig.2 Comparison of flow coefficient between experimental data and numerical simulation

本文通过对比调节阀固定开度α=80°时,数值仿真获得的阀门流通面积(离散点)和实验测量数据,验证仿真方法的准确性。如图2所示,本文针对常温水和不同温度下的液氧,开展了变出口压力工况仿真,结果表明流通面积稳定在实验数据附近,表明了本文数值计算方法对不同介质、不同工况的适应性较好。值得注意的是,空化产生的空穴结构会堵塞流道,进而影响阀门流通能力,降低流通面积,这可以解释图2中出口压力最小时,流通面积低于实验数据。而出口压力最大为2.9 MPa时,3种结果均为无空化工况,数值仿真所得阀门流通面积相似,并且与实验数据吻合较好。

图3给出了球阀在工况1~工况4下中心平面流道中心线位置(如图1虚线所示)的压力分布,横坐标z=0 m表示球心位置,右端为入口,左端为出口。不同工况下压力变化趋势基本一致,介质从入口开始流动后,压力呈现缓慢下降特征。在z=0.08 m位置压力开始急剧下降,到球心z=0 m位置附近达到压力最小值,随后压力开始急剧回升。在z=-0.05 m和z=-0.1 m时分别达到一个上升极值和下降极值,随后介质向出口流动,压力开始回升。pout分别为2.3 MPa和2.9 MPa时,压力最小值分别为0.87 MPa和1.93 MPa。上述分析表明介质流过阀芯时,压力变化并非单调减小和单调增加两种情况,而是分为缓慢下降、急剧下降、急剧回升、下降和回升这5个阶段。

图3 不同压差下的球阀流场中心线压力分布(介质为水)

Fig.3 Pressure distribution at the center line of ball valve under different pressure differences(medium is water)

z>0.1 m时,压力缓慢下降是管道内存在流阻损失造成的。z=-0.1~0.1 m范围内压力变化包含了急剧下降、急剧回升和缓慢下降3个阶段,为了研究每个阶段介质演化特征,图4给出了z=-0.1~0.1 m这5个水平截面的速度和压力云图及流线分布(Δz=0.05 m)。介质从进口管道进入球阀后,由于阀芯流道α=80°,流道横截面积急剧减小,速度急剧增加,速度由65 m/s增加到80 m/s,对应的压力云图由红色变为黄色,造成压力急剧下降约 0.8 MPa。当介质到达球心位置左右,即图4中间横截面位置附近时,流道面积达到最小值,此时速度最大,压力最小。在z=0 m水平截面上,球阀圆柱流道内观察到右侧的红色高速区和左侧的蓝绿色低速区。左侧的绿色低速区存在一对显著的漩涡结构。随着介质的进一步向下流动,流道面积增加,速度急剧减小,压力开始急剧回升,至z=-0.05 m时,即图4中第4个横截面,为球阀旋转流道出口,此时流道横截面积增加至最大值,速度最小,压力最大。

图4 球阀不同高度横截面速度云图和流线分布及压力云图(pout=2.3 MPa,介质为水)

Fig.4 Distribution of streamline, velocity and pressure contours at different positions (pout=2.3 MPa, medium is water)

随着介质流出旋转流道,从第4个横截面向第5个横截面流动时,如图4(b)压力云图所示,z=-0.1 m水平截面观察到左侧绿色中速区域、中间红色高速区域和右侧蓝色低速区域。在红色高速区以外均观察到了呈对称分布的6个漩涡结构,表明介质在阀芯出口位置流场结构十分复杂。中心压力观察到0.02 MPa左右的轻微下降。这是因为z=-0.1 m平面比z=-0.05 m平面多出了数个漩涡。在有漩涡的情况下,轴向局部流速受影响会增加,漩涡数量增多,导致了压力的轻微下降。在z<-0.1 m时,流道横截面不再变化,横截面漩涡最终都会消失,流速下降,导致压力缓慢上升。

上述基于二维截面的漩涡结构分析不足以完全表征三维流场湍流特征,图5给出了pout分别为2.3 MPa和2.9 MPa时的Q等值面分布(Q=4×107)。Q等值面的颜色表征速度的大小。由图5可以观察到Q等值面基本分布在变截面位置,比如进口管道和阀芯之间、阀芯和出口管道之间,因为在变截面位置存在较大的速度梯度。pout=2.3 MPa时,阀芯流道内部观察到两个细长弯钩结构,这是因为随着截面的变化,每一个水平截面的高速区和低速区分界面向左侧移动(见图4),分界面位置存在较大的速度梯度,因此阀芯流道内部存在Q等值面。而在pout=2.9 MPa时,出口压力较大,流量较小,未观察到阀芯流道内的Q结构。

图5 不同压差Q分布(Q=4×107)

Fig.5 Distribution of Q structures under different pressure differences(Q=4×107)

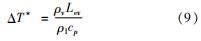

液流实验中常常听到汽蚀噪声,这是因为水流过阀芯,由于局部压力低于饱和蒸气压时发生了空化现象。该球阀实际工作介质为液氧,温度范围为95~100 K。图6给出了不同介质不同温度下数值仿真得到的气相体积分数等值面。随着出口压力的降低,空化区域逐渐增加,空化区域的大小取决于空化数,其表达式为

由图6可知,相同压差下常温水空化区域比95 K和100 K液氧介质小,这是因为相同压差时,常温水的空化数比液氧大0.1(见图7)。空化数越小,空穴发展越剧烈,空穴体积越大。对于常温水,σ=1.38时未观察到空穴结构,σ=1.17为初生空化,位于阀芯入口上壁面位置。随着出口压力的进一步降低,空穴结构向阀芯流道发展。液氧空穴体积随出口压差的变化趋势与常温水一致。虽然95 K空化数比100 K大0.04左右,但是对比95 K和100 K液氧结果可知,100 K时空穴体积小于95 K。这是因为随着液氧来流温度的增加,介质的热力学效应对空穴的发展过程起主导作用。而热力学效应会抑制空穴的发展,当液氧温度由95 K增加到100 K时,热力学效应的抑制作用远大于空化数减小的影响,因此100 K空穴体积小于95 K。对于常温水,发生空化的临界空化数为1.38左右(见图7)。

图6 不同温度下液氧流动的阀芯空穴分布(αv=0.1, pin=5 MPa)

Fig.6 Cavity structures of liquid oxygen flow under different temperatures(αv=0.1, pin=5 MPa)

图7 不同工况下空化数随出口压力的变化(pin=5 MPa)

Fig.7 Variation of cavitation number with the outlet pressure under different operating conditions(pin=5 MPa)

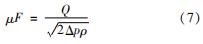

热力学效应的大小通常可以用名义温降ΔT*表征,即

名义温降仅与流体介质的物质属性相关。如图8所示,随着来流温度的升高,名义温降逐渐增加。常温水的名义温降ΔT*仅为0.008 K,而95 K和100 K液氧的名义温降分别为0.76 K和1.12 K。名义温降ΔT*合理地解释了常温水中热力学效应通常被忽略的原因及液氧的热力学效应明显强于常温水。

受热力学效应的影响,与常温水相比,液氧球阀内部流动温度变化和温度变化对空化的影响不可忽略。液氧各个工况下阀芯温度云图如图9所示。温度云图分布与空穴结构基本一致,表明空化区域存在显著的温降。随着空化数的降低,温降区域逐渐向阀芯流道发展。T分别为95 K和100 K时最大温降分别为2.5 K和1.5 K。

图8 液氧和水的名义温降ΔT*随温度的变化

Fig.8 Variation of nominal temperature with temperature of liquid oxygen and room-temperature water

本文通过数值仿真研究了某型调节阀在发动机额定工况压差和开度时的流场特性和空穴结构,为了模拟液氧热力学效应对球阀流动的影响,空化模型采用了考虑汽液相间对流传热的热力学修正模型。不同工况下数值计算获得的流通面积与液流实验数据基本吻合,验证了数值模型的准确性。讨论了球阀内部流道压力、温度、涡和空穴结构的分布特性及不同工况下的演化规律,得到的主要结论如下。

1)工质流经球阀,受流道几何结构变化的影响,压力变化分为缓慢下降、急剧下降、急剧回升、缓慢下降和缓慢回升这5个阶段。介质在阀芯流道内部流动时,截面速度区域分为高速区和低速区,两个区域分界线上存在较大的速度梯度,并在阀芯流道内部观察到了显著的Q等值面结构,表明流道内的涡量较大。随着压差的减小,阀芯流道漩涡结构消失。

2)相同压差时,水的空化数大于液氧。随着液氧温度的升高,空化数逐渐减小。空穴结构主要分布在阀芯入口,随着空化数的降低,逐渐向流道内部发展。空穴结构的发展受空化数和热力学效应的耦合影响。液氧温度由95 K上升到100 K时,空化数减小,名义温降增加,此时热力学效应影响占据主导作用,所以尽管空化数减小,空穴结构反而增加。对于常温水,发生空化的临界空化数为1.38左右。