基金项目:国家重点实验室基金(HTKJ2021KL011004)

作者简介:闫松(1988—),男,博士,高级工程师,研究领域为液体火箭发动机结构动力学、视觉测量技术。

1.航天液体动力全国重点实验室,陕西 西安 710100; 2.西安航天动力研究所,陕西 西安 710100

1.National Key Laboratory of Aerospace Liquid Propulsion, Xi'an 710100, China; 2.Xi'an Aerospace Propulsion Institute, Xi'an 710100, China

liquid rocket engines; 3D-SLDV; high-speed 3D-DIC; impeller; operational deflection shape

DOI: 10.3969/j.issn.1672-9374.2024.02.011

液体火箭发动机工作时受到涡轮泵、燃烧室和发生器等多源载荷共同作用,激励频率宽,掌握发动机结构动特性对于避免结构共振问题至关重要[1]。目前发动机涡轮盘等结构的模态测试通常采用粘贴加速度传感器的测试方法[2],这种测试手段往往由于测点数量有限,难以获得发动机结构振动细节,若要识别高阶振型需要大量布置加速度传感器,一方面耗费大量人力物力,另一方面传感器会引入附加质量改变发动机结构的动力学特性。

为了获得结构全场模态特性,已经开发了许多全场振动测量技术,如电子散斑干涉技术(electronic speckle pattern interferometry,ESPI),全息干涉测量(holographic interferometry),连续扫描激光多普勒测振仪(continuous-scan laser Doppler vibrometry,CSLDV)[3-6]。其中已经成熟应用于发动机结构模态测试的是激光多普勒测振仪(laser Doppler vibrometry,LDV),激光测振仪通过测量反射光的多普勒频移来检测运动物体的速度,速度可以进行积分或微分,以确定被测结构的振动位移或加速度。CSLDV是传统激光多普勒测振的扩展,其中激光点不是停留在固定位置,而是在测量表面上连续移动,与传统的LDV相比,连续移动点的好处是提高了测量分辨率,并显著减少了测量时间,已经开发了多种算法来确定沿着激光扫描路径的结构变形。为了进一步实现对工程复杂结构的全场扫描测量,发展了基于智能机器人平台的三维扫描测振系统(3D scanning laser Doppler vibrometer,3D-SLDV),该系统包括安装在工业机器人机械臂上的3个扫描式激光多普勒测振仪,可以快速定位扫描头,覆盖复杂结构的所有感兴趣表面,该技术在汽车模态测试中得到广泛使用[7]。文献[8-9]采用该技术实现了发动机推力室、导管等结构的全场模态测试,得到了发动机结构高分辨率模态振型,用于发动机结构动力学模型修正。

计算机和数字成像技术使得(digital image correlation,DIC)方法能够测量振动结构的形状和变形。DIC方法通过在结构表面喷涂高对比度散斑,使用相关函数找到参考图像和目标图像匹配区域的精确位置,据此实现全场变形的测量。早期DIC技术主要应用于准静态试验,随着CMOS高速摄像机的普及,出现了大量基于高速DIC的全场振动和变形测试研究[10-13]。Rizo-Patron等[14]使用DIC技术拍摄梁的变形图像,采用Ibrahim时域法从变形数据中确定梁的固有频率、振型和阻尼比等模态参数。美国NASA格伦弹道冲击研究实验室广泛采用高速DIC技术验证和迭代LS-DYNA模型,以研究泡沫对C-C结构的撞击影响。Schmidt等[15]使用一对同步的高速相机提供结构的全场动态变形、形状和应变信息,所获得的数据信息相当于数千个应变片,典型的数据采样率是27 000帧/s,位移精度为25~50 μm,应变精度为250~500微应变。Trebuňa等[16]针对商业DIC软件Istra4D不能直接用于模态参数估计的问题,通过修改高速相关性系统用于试验模态和工作模态分析,开发了Modan 3D软件用于提取结构的固有频率、振型和阻尼比。

DIC技术属于基于位移的测试方法,实际用于高频测量时由于高阶模态的位移很小,造成DIC对高频振型特别是面外振型的分辨力下降。Beberniss等[17]在使用高速DIC进行模态测试时,采用0.5g的电磁振动台激励弯梁,发现DIC测量500 Hz以上的响应时遇到了本底噪声,而激光测振仪准确地捕捉到了梁结构2.5 kHz内的响应。Ehrhardt等[18]通过梁结构和板结构在稳态正弦激励下的响应测量,比较了CSLDV和3D-DIC技术所得的固有频率和振型,两种测量系统在多数情况下都给出了类似的结果,3D-DIC对于结构大振幅下的空间复杂变形更精确,而CSLDV对于低振幅和空间变形模式简单的情况更精确。Beberniss等[10]研究了利用高速3D-DIC进行各种随机振动测量的可行性,并将DIC所得固有频率、阻尼和振型结果与LDV测量结果进行了比较,结果表明3D-DIC振动测量所得面外灵敏度比LDV低几个数量级,更难测量更高频率的位移。在传统测试方法失效的场合,DIC被证明是测量结构振动的有效替代手段。

本文以发动机离心轮为研究对象,通过力锤施加激励载荷,分别采用3D-SLDV和高速3D-DIC技术获得了离心轮5 kHz内的各阶工作变形,从测试过程和测试结果上对比分析了两种测试方法的优缺点,为发动机结构全场模态测试提供技术手段。

LDV技术的测试原理基于光学多普勒效应,当光从运动物体表面反射时,光的频率会发生改变,频率改变量与被测结构的振动速度有关,即

Δf=2v/λ (1)

式中:Δf为频率变化量; v为运动物体表面的移动速度; λ为激光的波长,对于氦氖激光,波长为632.8 nm。

单台激光测振仪可以测量沿激光轴方向的振动速度分量,假设L1为沿第一个激光头的单位方向矢量,且

L1=(l1x l1y l1z) (2)

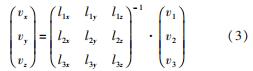

3D-SLDV技术同时使用已知空间坐标的3个激光测振仪聚焦于同一点,测试该点沿3个激光轴的振动速度v1、v2和v3,则被测点沿空间规定x、y和z方向的振动速度求解过程为[7]

扫描式激光测振仪可以对结构某一区域进行扫描测量,实际测量中,3台扫描式激光测振仪安装于机器人机械臂上,通过机械臂的移动实现对发动机结构不同区域的扫描测量,最终得到发动机整体结构的测试数据,详细的测试过程可以

参考文献[9]。

图1显示了3D-DIC的工作原理,基于两台不同视角的相机拍摄发动机振动过程中的图像序列[19]。首先通过双目立体标定技术获得相机内、外参数及两台相机的相对位置,建立图像中像素坐标与真实物理空间坐标的对应关系。其次执行相关性计算(立体匹配),相机1的第一张图像用作参考图像,与同时刻拍摄的相机2的图像进行比较,参考子集和目标子集之间进行相关性计算,根据测试前标定的摄像机关系,将对应的像素点坐标转化为空间中的三维点坐标。随时间进行时序匹配,因此可以随时间跟踪每个测量点,从而对试样的表面进行变形跟踪。相关性计算过程对图像有一些内在的要求,图像必须存在对比度以便跟踪特征,子集中包含3~5个特征,并在整个图像集中进行跟踪,通常在结构表面人工制作高对比度黑白散斑。子集通过分配所谓的形函数使得变形受到限制,但对噪声具有更高的鲁棒性。形函数结合亚像素精度的图像插值,可以对形状和位移进行高质量和精确的测量。最后根据需要导出其他量,通过计算相邻点之间的相对位移来识别应变,可以根据拍摄帧速率导出速度、加速度等[20]。

在离心轮后盖板上内外两圈各粘贴16个反光片,共布置32个测点,如图2所示。

测试采用Polytec PSV-400-3D激光测振仪进行,该激光测振仪可以获得特定频率下工作变形(operational deflection shape, ODS),对于非密集频率得到的结构工作变形可以认为是该阶模态。通过移动机械臂调整激光扫描头的位置,使得激光扫描头正对离心轮。采用力锤(型号:B&K8206)敲击离心轮后盖板外缘提供脉冲激励,使用金属锤头以获得高激励频率带宽。力锤每敲击一次,3台激光测振仪同时采集某一测点的时域响应数据,每个测点敲击5次进行幅值平均,以提高信噪比。该测点采集完成后,扫描点自动跳到下一测点,重复测量过程直到所有测点完成采集。分析频率带宽为0~6.4 kHz,谱线数为6 400,频率分辨率为1 Hz。

3D-DIC测试时采用与3D-SLDV测试时相同的安装方式。在离心轮表面制作高对比度黑白散斑,使用高速DIC重复试验,试验现场如图3所示。采用两台高速相机拍摄力锤敲击下离心轮的动态响应,该相机在1 280×896分辨率下最高帧速率达65 000 帧/s。试验过程中采用85 mm定焦镜头拍摄,曝光时间5 μs,帧速率30 000 帧/s以捕捉关心的离心轮模态,两台无频闪补光灯从不同方向照射离心轮,解决高速拍摄时曝光时间短进光量不足的问题。力锤敲击时同步触发高速图像采集系统记录离心轮的振动响应,采集1 s时长数据,两台相机各拍摄30 000张图像。

拍摄完成后,通过千兆网线将相机内存中图像下载到计算机硬盘,采用VIC-3D软件执行相关性计算,如图4所示。子集大小为29,步长为7,位移计算完成后利用FFT模块进行离心轮全场模态分析。

从测试过程来看,3D-SLDV测试相当耗费人力,由于一般激振器无法提供5 kHz以上的激励,本次离心轮激励采用力锤敲击。每一个测量点都需要5个谱平均值,32个测点需要试验人员至少敲击160次离心轮。每个点单次激励的准备和采样时长约为12 s,每个点顺序获取数据的过程大约需要32 min。然而,与获取数据所需的时间相比,3D-SLDV技术的处理时间相对较短,在不到1 min的时间内完成工作变形计算。对于3D-DIC测试,获取数据的时间非常短,只需要采集1 s的响应数据,力锤只需敲击一次,产生60 000张图像共64 GB数据,但数据的传输和分析耗时较长,从高速相机内存下载到计算机用时12 min,而对30 000张图像进行相关性计算大约花费3.4 h,高速DIC的处理时间是使该方法失去效率的重要环节。

从测试结果来看,图5给出了3D-SLDV和3D-DIC两种方法所得全场平均位移的频域结果对比,表1给出了两种方法所得固有频率的结果对比。

其中1 kHz以下的频率与离心轮安装状态有关,两次测量1 kHz内的频率差异是由于两次安装的拧紧力矩不同,重点关注1 kHz以上的离心轮自身的节圆和节径振型,两种方法得到的固有频率差别最大仅为0.11%。

图5 3D-SLDV和3D-DIC所得全场平均位移频域结果对比

Fig.5 Comparison of the frequency-domain results of the full-field average displacement obtained by 3D-SLDV and 3D-DIC

在1~5 kHz频率范围内3D-SLDV技术共捕捉到6阶振型,而3D-DIC技术捕捉到4阶振型,如图6

所示。从图5中可以看出,DIC技术是基于位移的测试技术,本次实验关注的离心轮节圆和节径振型均是离面振型,3D-DIC技术存在明显的本底噪声,对于本次测试,相机分辨率为1 280×896,相机镜头距离离心轮约为0.65 m,相机视野为420 mm×265 mm,相机夹角为29.22°,可以捕捉的最小位移为12.5 nm,在图5中表现为一条水平线,DIC系统无法识别低于该位移的高阶振型。相比较而言,3D-SLDV技术可以识别的最小位移量级小于6.5 pm,对于节圆和扭转两阶振型的响应幅值由于小于DIC系统的本底噪声而无法被DIC系统捕获。从振型的精细程度来看,3D-SLDV技术的32个测点对于识别四节径振型显然是勉强的,更高频率的振型由于测点数量不足而无法辨识,因此本文未分析5 kHz以上的振型。当然可以通过布置更多的反光测点获得更加精细的振型,但这会进一步增加测试时间和人力成本。相比较而言,3D-DIC捕捉到了振动结构的局部变化,其细节程度是3D-SLDV技术难以实现的。

图6 3D-SLDV和3D-DIC所得工作变形对比

Fig.6 Comparison of operational deformation shapes obtained by 3D-DIC and 3D-SLDV

值得注意的是,DIC测量分辨率通常与测量体积成线性关系,如果灵敏度需要增加一个数量级,则测量体积需要减少一个数量级。根据上述测试过程和测试结果,使用DIC方法测量发动机结构振型是很有潜力的,在振动测量中优势如下:①采集时间很短,数据分析可实现自动化,一次可识别多个ODS或频率; ②对刚体运动不敏感,对大位移测量更有优势; ③振型的细节描述非常好,可以同时计算上千个点的位移,可以以纳米级精度测量3D全场高频ODS; ④高速相机价格比3D-SLDV便宜,可同时测量应变。但该方法也有一些局限性:①最高可测频率在很大程度上取决于所使用的相机,且随着帧速率的增加,分辨率会降低; ②随着视场增加,测量的平面外分辨率成比例地降低; ③DIC是一种位移测量技术,因此结构位移必须大于系统的本底噪声。对于高频振动的结构,加速度量级可以很容易地使用加速度传感器测量,高频振动的位移量级可能远低于DIC测量的本底噪声。

实际应用中,3D-SLDV和3D-DIC两种技术均能获得结构全场振型。高分辨率(≥400万像素)高速相机的普及可以进一步提高高速3D-DIC技术的模态测试能力,这种基于图像的测试技术也更容易与运动放大等视觉技术结合,得到良好的结果,但其所耗费的时间使该方法目前仅可用于研究性试验,而非大规模工程应用。

采用3D-DIC和3D-SLDV技术开展了液体火箭发动机离心轮模态测试,得到了离心轮5 kHz以内的频率和振型,两种测试方法都能得到结构全场振型,得出如下结论。

1)3D-DIC技术采集时间短,测试和分析时间较长,可通过一次敲击测试得到多个频率和ODS,但存在本底噪声影响,可能存在模态遗漏。

2)3D-SLDV技术采集时间较长,但位移分辨率要比3D-DIC系统高3个数量级以上,对于高频振型辨识更有优势,但增加测点数量会显著增加测试人员工作量。

3)3D-DIC技术可与图像处理技术结合,描述的振型细节更加丰富。