作者简介:张凭(1993—),男,博士,工程师,研究领域为液体火箭发动机组件疲劳寿命。

1.航天液体动力全国重点实验室,陕西 西安 710100; 2.航天推进技术研究院,陕西 西安 710100

1. National Key Laboratory of Aerospace Liquid Propulsion, Xi'an 710100, China; 2. Academy of Aerospace Propulsion Technology, Xi'an 710100, China

copper alloy; ductility; necking; stress-strain curve; uniaxial tension; correction

DOI: 10.3969/j.issn.1672-9374.2024.02.014

备注

作者简介:张凭(1993—),男,博士,工程师,研究领域为液体火箭发动机组件疲劳寿命。

引言

应变局部化是金属材料甚至岩土材料中常见的现象[1],核心特征为同质变形或应变场向非均匀或非连续场过渡,引起局部应变集中[2]。同时结构全局力学响应表现出应变软化行为,应力-应变曲线出现负切线模量,结构承载能力迅速下降并导致失效[3]。颈缩是金属材料单轴拉伸试验中常见的应变局部化现象,当拉伸阶段后期材料硬化与承载截面缩小的影响达到平衡时,试件形貌、表面状态和内部组织等细微缺陷即可引发应变局部化,原本均匀变形的等截面试件出现颈状收缩,载荷-位移曲线达到峰值并迅速下降,试件最终因有效承载截面不足而突然断裂。

一般来说,金属材料延性越高,颈缩现象越明显[4],而试件颈缩后的拉伸数据不能完全反映材料的实际承载性能,为此学者开展了一系列颈缩后拉伸曲线修正方法的研究。Bridgman[5-6]首次提出基于试棒颈缩半径和曲率的应力-应变曲线的修正方法,文献[7-8]也提出了类似的理论,但上述方法仅适用于圆棒试件,且颈缩区域几何参数的实时测量难度高,难以工程应用[9]。Bridgman同时提出了多项式经验函数的修正方法,但仅适用于钢材料的近似估计[4]。随着数字图像相关(DIC)等先进测量手段的出现,上述模型得到了衍生发展,同时也出现基于DIC测量与仿真修正的真实应力-应变曲线试验方法[9-10]。如Joun等[11]基于体积不变假设提出了一种耦合二维DIC和有限元模拟的大应变域应力-应变曲线获取方法。Zhu等[12]采用三维DIC技术跟踪低碳钢的单轴拉伸变形过程,通过颈缩区域曲率计算截面积并获得材料的真实应力-应变曲线。以上方法为应变局部化现象的研究提供了新的视角,但仍较难直接应用于工程领域。

同时,也有学者从数值试验的角度开展研究。通过假设颈缩后应力-应变关系,借助有限元建模仿真颈缩过程并提取载荷-位移特性与试验数据进行对比,从而获得修正模型的关键参数。此类方法仅需单轴拉伸试验的载荷-位移曲线,因此工程适用性较好。如Ling[13]分析了Bridgman方法的局限性并提出基于上下限假设的加权平均修正方法,通过有限元模拟颈缩过程并拟合加权因子,最终获得材料颈缩后真实应力-应变特性。Jia等[14]在此基础上提出了基于线性硬化假设的修正加权平均法,对低碳钢SS400开展单轴拉伸试验并利用二维激光位移计测量最小截面直径,有限元模拟表明该方法对低碳钢的颈缩后应力-应变曲线描述效果较好。Shahrjerdi等[9]综合Bridgman方法和图形处理技术验证了通过有限元颈缩模拟修正响应曲线的合理性。Zhu等[3]提出了包含非局部塑性应变项的响应修正方法并验证了其在钢材中的适用性。以上数值研究表明,修正方法的效果与材料密切相关[13],需根据材料性能进行调整。

本文研究对象为延性铜合金,其因优异的导热性和延展性而被应用于液体火箭发动机再生冷却推力室内壁的制造[15]。部分研究表明[16],推力室内壁的失效与延性耗竭密切相关,表现为循环大塑性变形下的超低周破坏,而材料在大应变域的力学响应对结构循环比变形分析及延性损伤的量化至关重要。在结构强度分析与试验中同样发现,该材料往往工作于塑性失稳破坏的临界载荷,甚至当变形集中区域应变远高于材料断后伸长率时,结构仍可继续工作而不发生显著失效。换言之,传统工程强度分析所采用的试验数据及本构关系已无法适应航天用延性铜合金的强度及寿命评估,需要研究适用于铜合金的颈缩后曲线修正方法,描述材料大应变域真实响应,充分发挥高延性材料的承载能力。

综上,由于无法有效处理拉伸试验颈缩后数据,传统工程强度分析所用材料本构无法充分反映延性铜合金的真实承载能力,而已有的颈缩后修正方法的工程易用性欠佳,同时其在航天用铜合金中的适用性有待研究。因此,本文针对某延性铜合金开展常温单轴拉伸试验,获得材料颈缩前后载荷-位移曲线。从工程强度分析的角度,提出通用修正函数与参数拟合原则,随后通过有限元颈缩仿真拟合修正因子并与加权平均法对比说明本文方法的合理性。

1 单轴拉伸试验

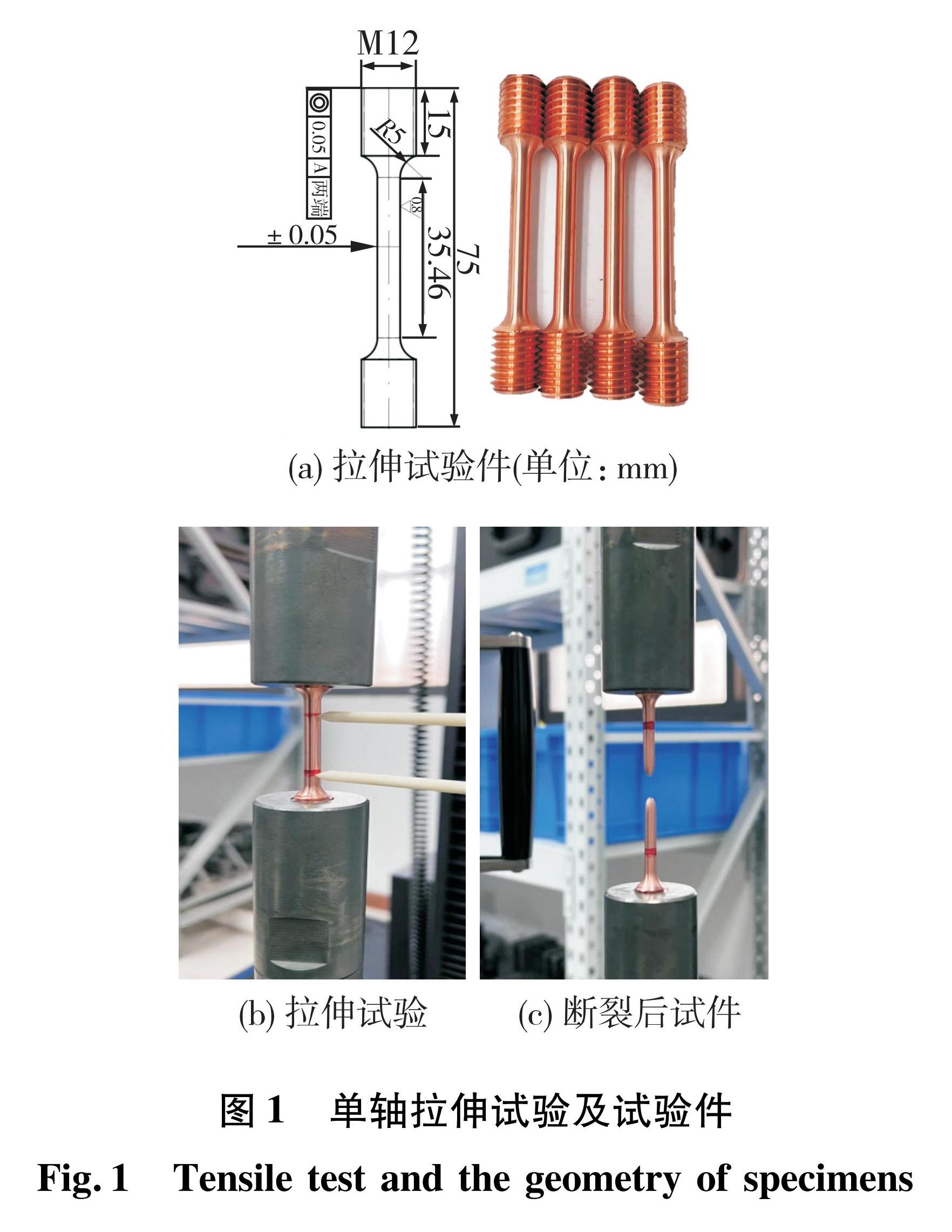

针对某延性铜合金开展常温单轴拉伸试验,设计并加工狗骨形试棒如图 1(a)所示。试棒轴向尺寸75 mm,两端螺纹夹持段与平直段圆滑过渡,平直段长度35 mm,直径5 mm。

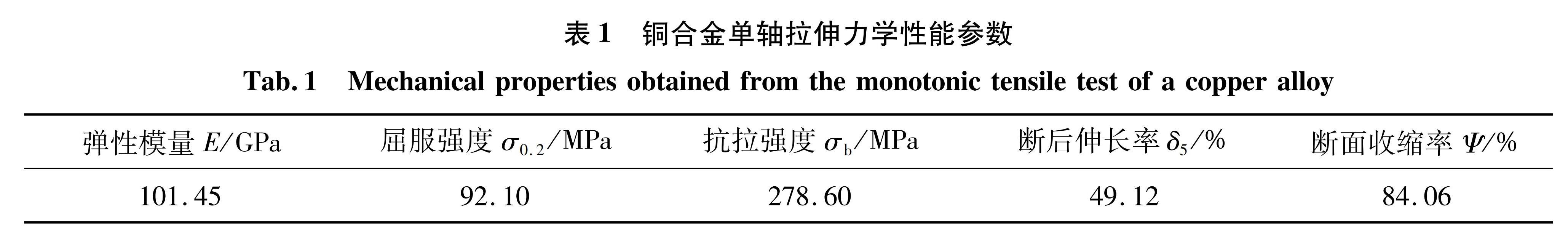

依据国标GB/T 228.1—2021《金属材料 拉伸试验 第1部分:室温试验方法》[17],采用100 kN电子万能试验机(型号UTM5105HB),在室温(20 ℃)下以0.5 mm/min的速率对于铜合金开展单轴拉伸试验直至断裂[见图 1(b)和图1(c)]。为分析材料应力-应变行为,采用夹式引伸计记录试件中心25 mm标距段的长度变化,得到试验过程中的载荷-位移曲线如图 2(a)所示,由此计算得到的工程应力-应变曲线如图 2(b)所示,试验得到的材料参数见表 1。

表1 铜合金单轴拉伸力学性能参数

Tab.1 Mechanical properties obtained from the monotonic tensile test of a copper alloy该铜合金试件在应变为0.3左右发生颈缩,但仍可继续承载,且载荷-位移曲线与脆性材料的急剧下降存在显著差异。其较高的断后伸长率和断面收缩率均表明该铜合金具有优异的延展性,因此有必要对其颈缩后特性进行研究,以充分利用材料的承载能力。

2 理论与方法

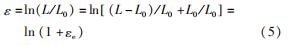

2.1 大应变域材料应力-应变关系材料的应力-应变响应对于工程结构设计与仿真分析至关重要,一般通过均匀截面试件的单轴拉伸试验获得。以A0和L0分别表示试件测试段的截面面积与长度,在试验中记录当前长度L与载荷P,则可定义工程应变和工程应力分别为

εe=(L-L0) (1)

σe=P/A0 (2)

由此可得到材料的工程应力-应变曲线。工程应力与应变不考虑横截面积及长度变化带来的度量差异,因此一般仅适用于小变形结构的分析。

大变形问题可采用真实应力与真实应变定义,以当前长度为参考时,对于给定长度增量dL,应变增量定义为

dε=dL/L (3)

则总应变(真实应变)ε为

由此可得ε与εe的关系为

真实应力σ定义为

σ=P/A (6)

式中A为当前截面面积,一般在试验中较难测量。

当弹性变形远低于非弹性变形时,可利用体积不变假设A0L0=AL得到

2.2 颈缩与应力-应变修正

2.2 颈缩与应力-应变修正对于延性金属材料制成的均匀截面试件,其在单轴拉伸过程中依次发生弹性变形、塑性变形,随后由于薄弱截面的集中变形而产生颈缩现象,此后截面积逐渐缩小并导致试件失效。颈缩发生时,材料由单轴受力状态转变为三轴应力状态[18],此时工程应变εe只是非均匀变形区域上的平均值,不代表最薄弱截面上的最大值。因此,颈缩后的真实应力与应变无法通过εe来进行换算,前述公式中仅有式(6)、式(8)和式(10)依然成立,而实际上颈缩后期的应力状态尤为复杂,环向拉应力的出现使得式(6)也不再适用[4]。

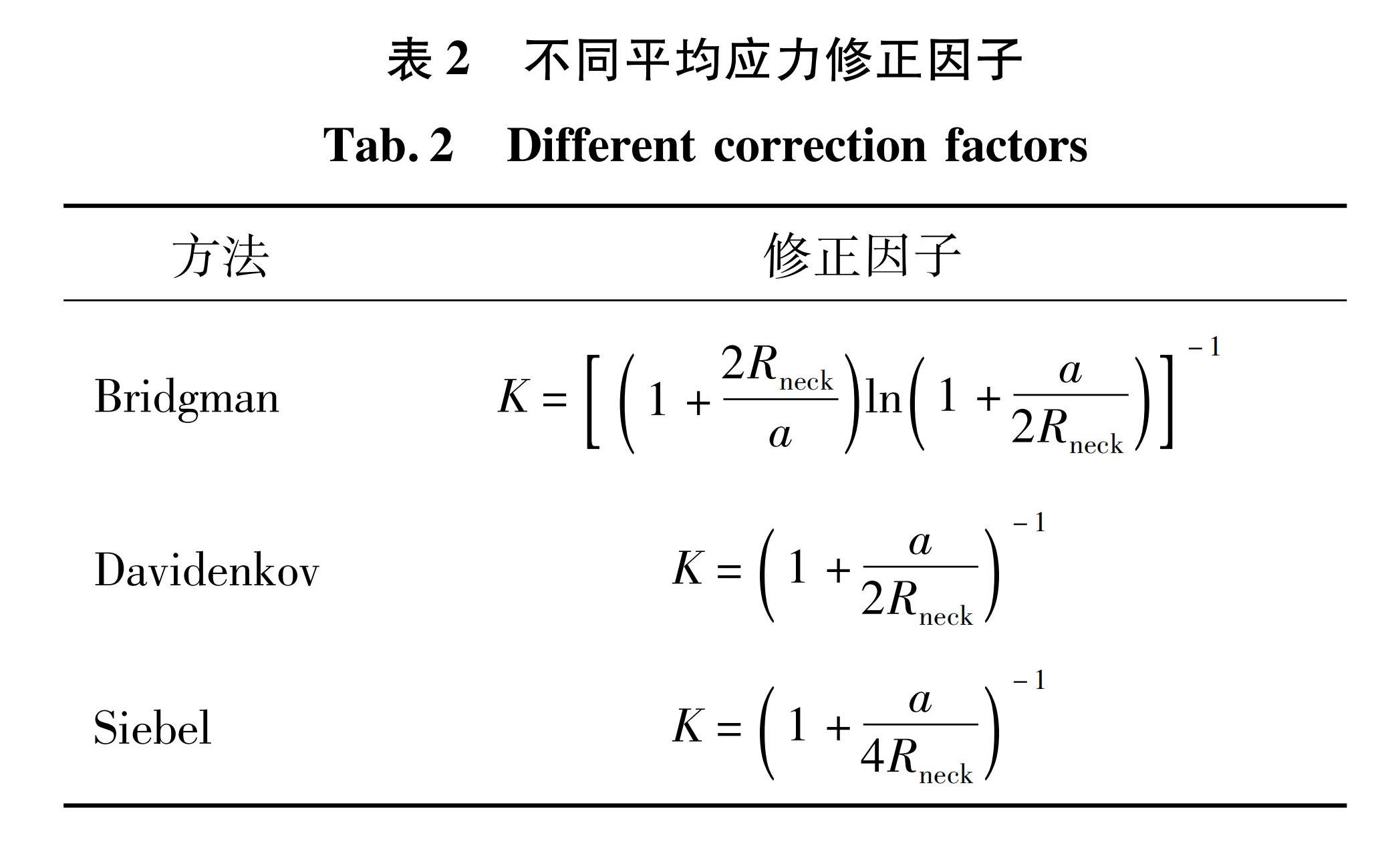

当圆棒形试件颈缩区域的曲率半径Rneck和最小截面半径a可实时测量时,基于文献[5,7-8]提出的方法对平均应力进行修正,即

σ'=Kσ (11)

式中K为修正因子,表达形式见表 2。

对于大多数仅可获得载荷-位移曲线的试验,可以假定应力-应变关系的修正函数,并借助颈缩过程的有限元仿真结果来校准修正参数。该类方法基于相同的颈缩判定条件,对式(6)和式(8)分别求微分得出

dP=Adσ+σdA (12)

dε=dln(A0/A)=dA/A0 (13)

假定颈缩发生在试件载荷-位移曲线峰值处,此时载荷增量dP=0,将式(13)代入式(12)得出

σu=dσu/dεu (14)

式中:σu、εu为颈缩点的真实应力、应变。

式(14)表明颈缩点的真实应力梯度(硬化模量)等于该点真实应力,可作为颈缩发生的判定条件,同时也作为颈缩后硬化模量的修正依据[19]。通过构造不同形式的硬化函数并设定上下限,可获得不同形式的应力-应变函数。如文献[13]假设颈缩后硬化模量的上限为σu,下限服从幂函数规律,定义基于加权平均因子k和指数m的颈缩后真实应力为

σ=σu[k(1+ε-εu)+(1-k)(ε/εu)m] (15)

文献[14]将下限规定为0,并假定颈缩后硬化模量为常数,给出修正加权平均方法,即

σ=σu[1+w(ε-εu)] (16)

式(16)仅包含单个修正因子w,且采用较简单的线性硬化假设,因此被大量应用于钢结构的超低周疲劳分析。

文献[9]给出二次函数形式的颈缩后应力-应变规律,即

σ=Aε2+Bε+C (17)

式中:A、B、C均为修正因子。

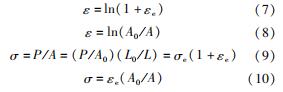

2.3 工程通用修正函数已有的颈缩后响应函数多从数学角度出发,其函数形式及假设条件不尽相同,在进行结构强度评估时易产生歧义及困难,不利于失效载荷的识别与评判。本文基于工程材料普遍认知与结构强度评估的一般性原则,提出颈缩后应力-应变特性应具有的规律为:①材料在屈服后不断硬化,且硬化模量受材料损伤影响逐渐降低,当硬化模量降为0后,孔洞等损伤急速累积,结构变形急剧增加并发生失效; ②颈缩点仅与结构几何与载荷状态相关,并非材料固有属性,因此材料应力-应变特性在颈缩前后应具有一致性和连续性; ③采用断面收缩率Ψ换算得到极限应变εf,作为材料的真实断裂应变的保守估计。

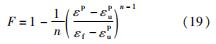

由此定义颈缩后真实应力修正的工程通用表达式为

σ=σu+σu(εp-εpu)F (18)

式中:F为硬化模量修正函数; εp和εpu分别为当前应变和颈缩应变的塑性分量。

则根据以上假设,F应满足如下条件。

其中条件4)与条件5)等效于硬化模量的上下限假设。在满足以上条件的基础上,可以构造出不同形式的硬化模量修正函数F,2.2节中的3种修正函数也可以在适当放宽上述条件的基础上获得。考虑金属材料应力与塑性应变经常满足幂函数关系[18],构造如下的指数形式修正函数。

式中n为修正因子。

此外,从结构强度安全性设计的角度,在基于有限元颈缩模拟对以上通用修正函数的参数进行识别时,应遵循如下原则:①预测颈缩点不应晚于试验颈缩点; ②预测载荷-位移曲线应始终位于试验曲线以下,以确保结构保守设计; ③曲线包含明显的载荷下降段,以识别结构失效载荷。

3 本构数值方法与对比

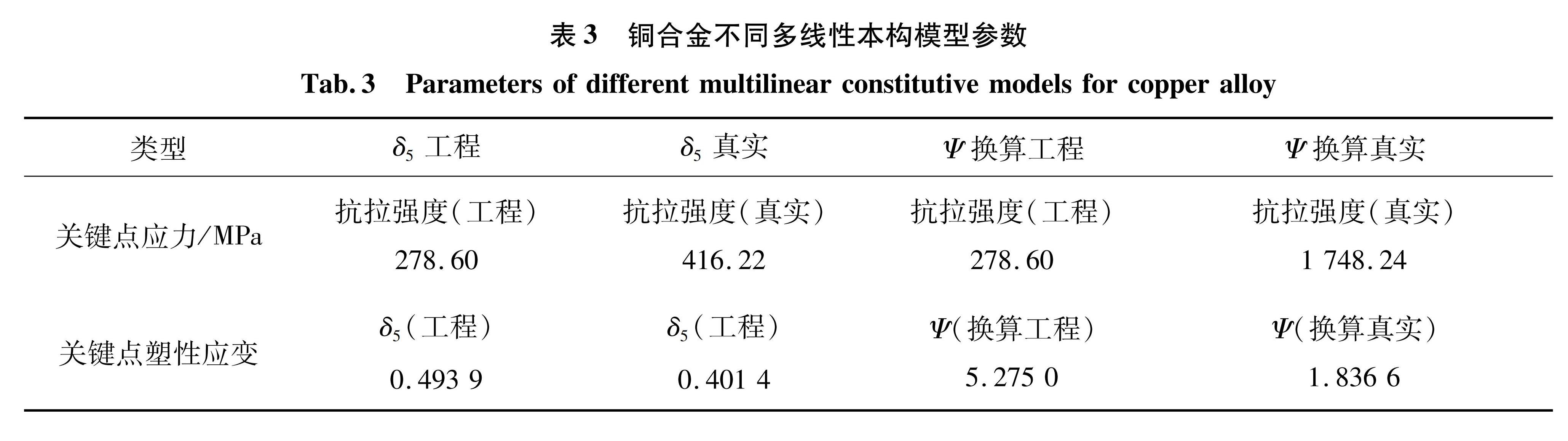

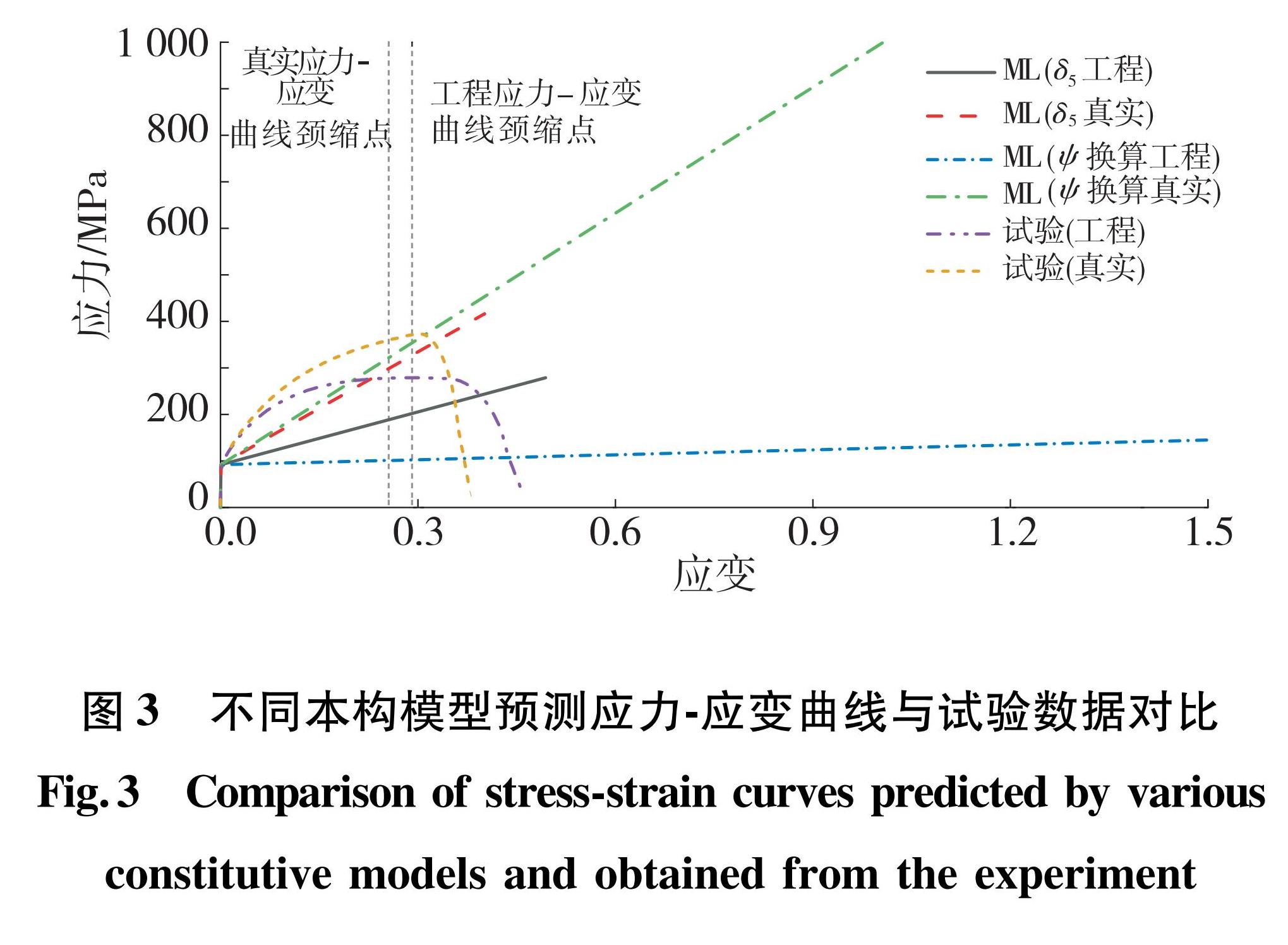

工程结构的强度分析多采用软件预置的多线性(ML)材料本构关系,既为降低分析复杂度与难度,也可应对试验数据缺乏的情况,而对于仅能获得表 1中参数的大多数金属材料,ML本构进一步简化为双线性本构。除用于计算弹性段变形的弹性模量与屈服强度外,仅需补充屈服后关键点应力与塑性应变即实现线性插值,同时根据应变水平采用工程或真实应力-应变数据。具体工程实践中,采用的几种本构形式及参数选取方法见表 3,其在分析中的合理性与精度将在后文进行对比。

以上各本构关系预测的应力-应变响应与试验数据的对比见图 3。从图3中可以看出,当应变高于5%时,试验工程和真实应力-应变曲线已存在较大差异,而延性金属材料的断裂应变一般较高,应对屈服后应力-应变数据进行转换。上述多线性本构均采用屈服点到断裂点的割线作为塑性段近似,当材料硬化模量衰减时线性假设失效,导致偏保守的性能估计; 而当存在明显颈缩现象时,抗拉强度与极限应变对应关系不再成立,或可导致偏危险的设计。换言之,分析延性材料在大应变域的响应时采用双线性关系的误差较大,无论如何选取关键点参数均存在过低或过高估计结构承载能力的风险。而试验真实应力-应变数据形成的多线性关系也仅在颈缩段前有效。

图3 不同本构模型预测应力-应变曲线与试验数据对比

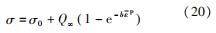

Fig.3 Comparison of stress-strain curves predicted by various constitutive models and obtained from the experiment为准确描述延性铜合金的塑性行为,本文采用双段函数描述真实应力-应变关系。结合铜合金塑性变形特征,采用式(19)描述材料颈缩后特性,采用如下的非线性各向同性硬化模型描述材料颈缩前硬化规律。

式中:σ0为初始屈服应力; Q∞为屈服面的最大硬化量; b为硬化参数; ε^-p为等效塑性应变,表达式为

式中εp为塑性应变分量。

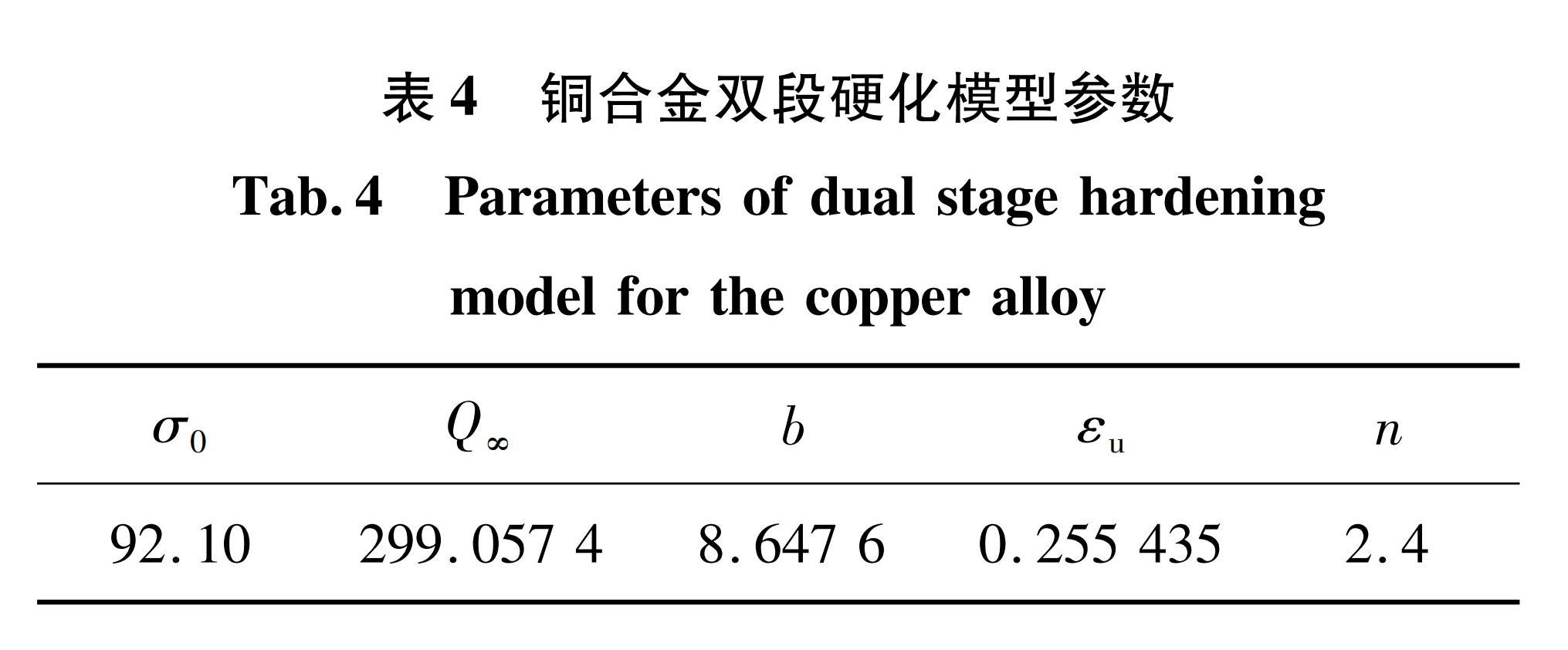

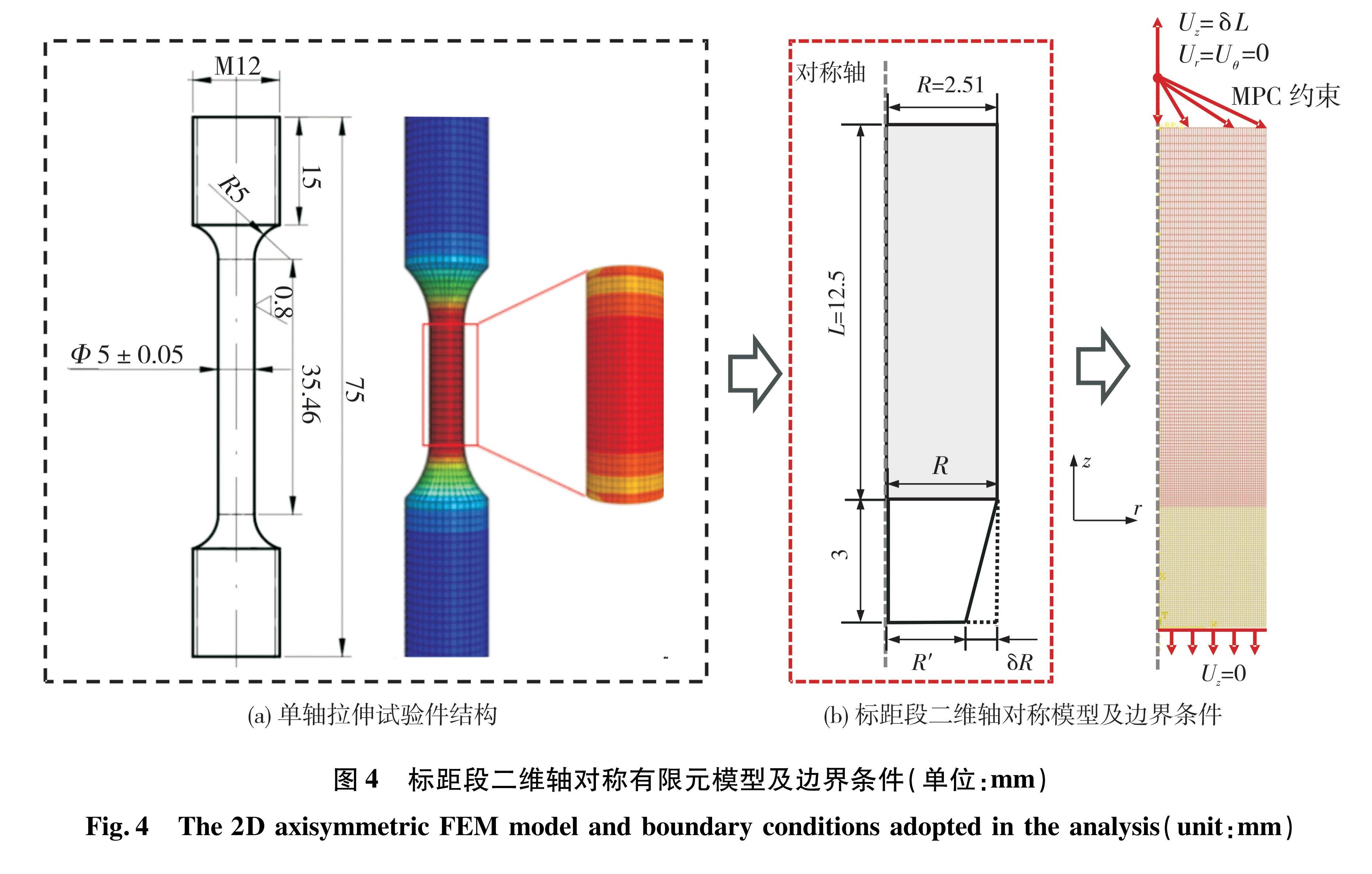

以上双段硬化规律基于ABAQUS的用户自定义硬化子程序UHARD实现,其中颈缩前硬化参数σ0、Q∞、b基于试验获得的颈缩前真实应力-应变曲线拟合得到,而颈缩后曲线修正因子基于后续有限元仿真优化获得,上述参数见表4。

4 颈缩仿真与分析

4.1 单轴拉伸试棒有限元模型为仿真单轴拉伸试验中试棒中心标距段的变形与颈缩过程,在商用有限元软件ABAQUS中建立如图 4所示的试件标距段二维轴对称模型。模型以试件轴线为对称轴,并取标距段子午面1/2建模以提高计算效率与一致性。为使试件在单轴拉伸载荷下发生颈缩变形,在标距段模型中心附近引入过渡段,使得标距段半径由R逐渐过渡为R'。该建模方式是引入颈缩现象的通用方法,当半径过渡量δR远小于试件半径时,其对承载面积的影响可被忽略,不会改变模型的载荷-位移响应。

图4 标距段二维轴对称有限元模型及边界条件(单位:mm)

Fig.4 The 2D axisymmetric FEM model and boundary conditions adopted in the analysis(unit:mm)模型采用双二阶轴对称单元(CAX8)以提高精度并捕捉颈缩现象,过渡区采用精细化网格,其他区域单元尺寸介于0.05~0.2 mm之间。模型下端面施加对称约束(Uz=0),令模型上端面中心为参考点RP并与上端面设置轴向多点约束,与参考点RP施加轴向强迫位移(Uz=δL)并约束其周向及径向自由度。

4.2 颈缩仿真结果与敏感性分析建立前述标距段二维轴对称模型,采用多线性弹塑性本构模型仿真颈缩过程,得到单轴拉伸不同阶段试件的几何形貌与塑性应变分布状态如图 5所示。

图5 不同变形阶段时试件的塑性应变仿真结果

Fig.5 The simulated results of plastic strain contour of speciment at various deformation stages由于过渡段的引入,模型中心段存在一定程度的应力集中[见图 5(a)],并随着载荷升高逐渐发生颈缩[见图 5(b)],此时颈缩区域的应变水平显著上升并达到材料的断裂极限,最终发生全截面失效[见图 5(d)]。以上结果表明,仿真得到的试件变形规律及失效特性与试验观测现象一致,可以正确描述材料的颈缩行为。

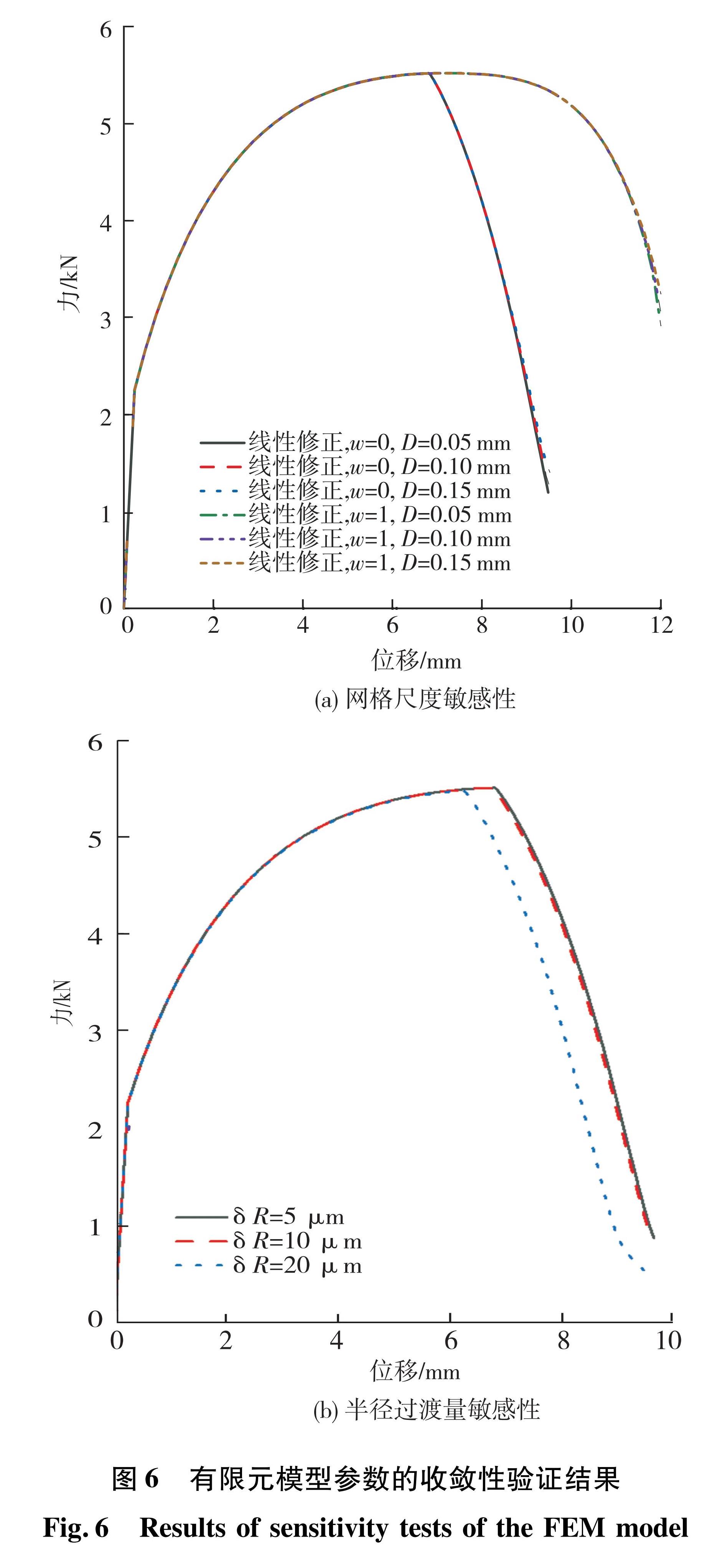

为保证后续仿真分析正确性及一致性,分析了模型网格尺度D及半径过渡量δR对模型载荷-位移响应特性的影响,得到不同参数值下载荷-位移曲线如图 6所示。

可以看出,该仿真方法得到的试件颈缩前后载荷-位移特性并不依赖于模型网格尺度D,只要有限元网格足以得到收敛的数值结果,则获得的颈缩特性即可认为有效。改变半径过渡量δR会影响模型的颈缩行为及响应特性,但随着δR逐渐减小,模型输出响应将收敛于稳定解。因此,在本文的分析中选取网格尺寸D=0.05 mm,并使半径过渡量δR=5 μm,相比于试件标称半径R=2.51 mm,其对承载能力的影响可忽略。

4.3 颈缩后曲线修正分析采用加权修正方法,仿真得到采用不同修正因子w对应材料性能时模型的载荷-位移曲线如图 7所示,由于加权修正仅影响颈缩后特性,因此图7中未绘制早期塑性变形阶段曲线。图 7表明,由于假定颈缩后硬化模量为0,采用加权修正w=0的模型过早地发生颈缩,且试件由于全截面失效而迅速破坏,预测的载荷-位移曲线远低于试验结果; 而假定颈缩后硬化模量为σneck的加权修正模型(w=1)给出了过高的载荷-位移曲线。当修正因子w介于0~1之间时,输出载荷-位移响应介于上述两个模型之间,虽然可以通过优化的取值以调整模型响应,但可从图 7中看出,该铬青铜材料的颈缩后硬化规律并不符合加权修正的线性硬化假设,无论如何调整修正因子w,预测的载荷-位移响应总会低估颈缩初期载荷并高估临近失效前的结构承载能力。根据2.3节中预测载荷保守性要求,选定w=0.75作为加权修正因子。

图7 不同修正w因子对应模型载荷-位移曲线

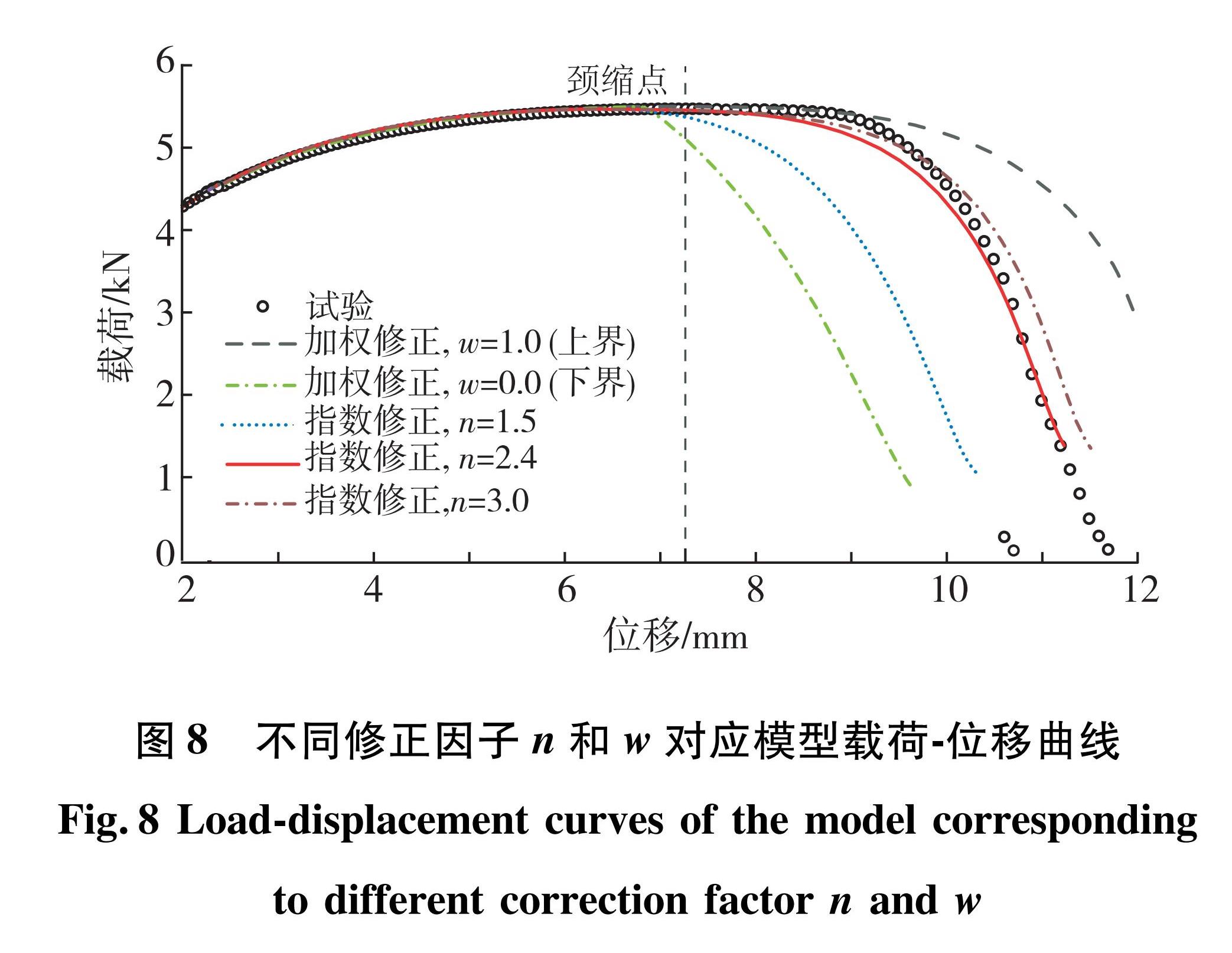

Fig.7 Load-displacement curves of the model corresponding to different correction factor w采用指数修正方法,仿真得到采用不同修正因子n对应材料性能时模型的载荷-位移曲线如图 8所示。观察曲线可知,由于依旧采用硬化模量上下限的假设,不同修正因子n所对应模型的预测响应均介于加权修正w=0和w=1之间。当增加修正因子n时,预测曲线逐渐上升,但其对参数的敏感性也逐步减弱,这是由指数函数特性所导致。根据函数特性可知,当n=1时,预测曲线将与加权修正w=0的曲线一致,而当n→∞时,预测曲线将与加权修正w=1的曲线重合。同时可以看出,由于假设颈缩后硬化模量加速衰减,指数修正模型预测的载荷-位移曲线与试验结果贴合程度更高,通过调整n的取值可得到较一致且偏保守的预测曲线。根据2.3节中对预测载荷保守性要求,选定n=2.4作为指数修正因子。

图8 不同修正因子n和w对应模型载荷-位移曲线

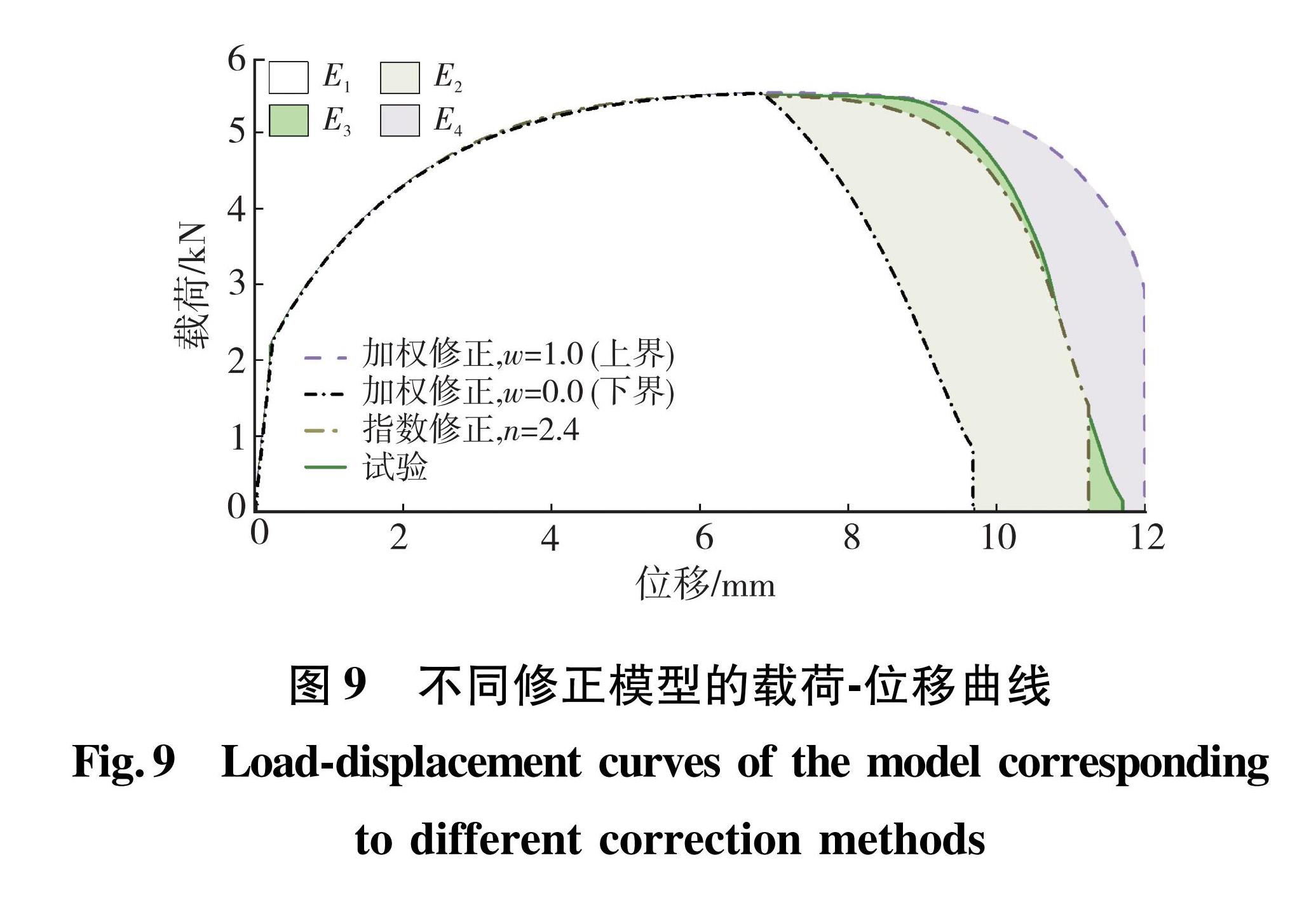

Fig.8 Load-displacement curves of the model corresponding to different correction factor n and w为进一步说明不同修正方法预测载荷-位移曲线的差异,图 9中对比了几种修正预测曲线下面积。对单轴拉伸试棒而言,曲线与位移坐标轴所围成面积即试件在失效前所能储备的变形能反映其承载能力。可以看出,由于载荷下降缓慢且延性较高,铜合金试棒在颈缩后仍具备较强的承载能力,颈缩后所吸收的能量占全部能量的1/3左右。采用加权修正w=0预测响应的能量E1和w=1的能量Ei分别低估和高估了结构承载能力,而指数修正n=2.4预测曲线与实际能量差异仅为E3,认为工程可接受。

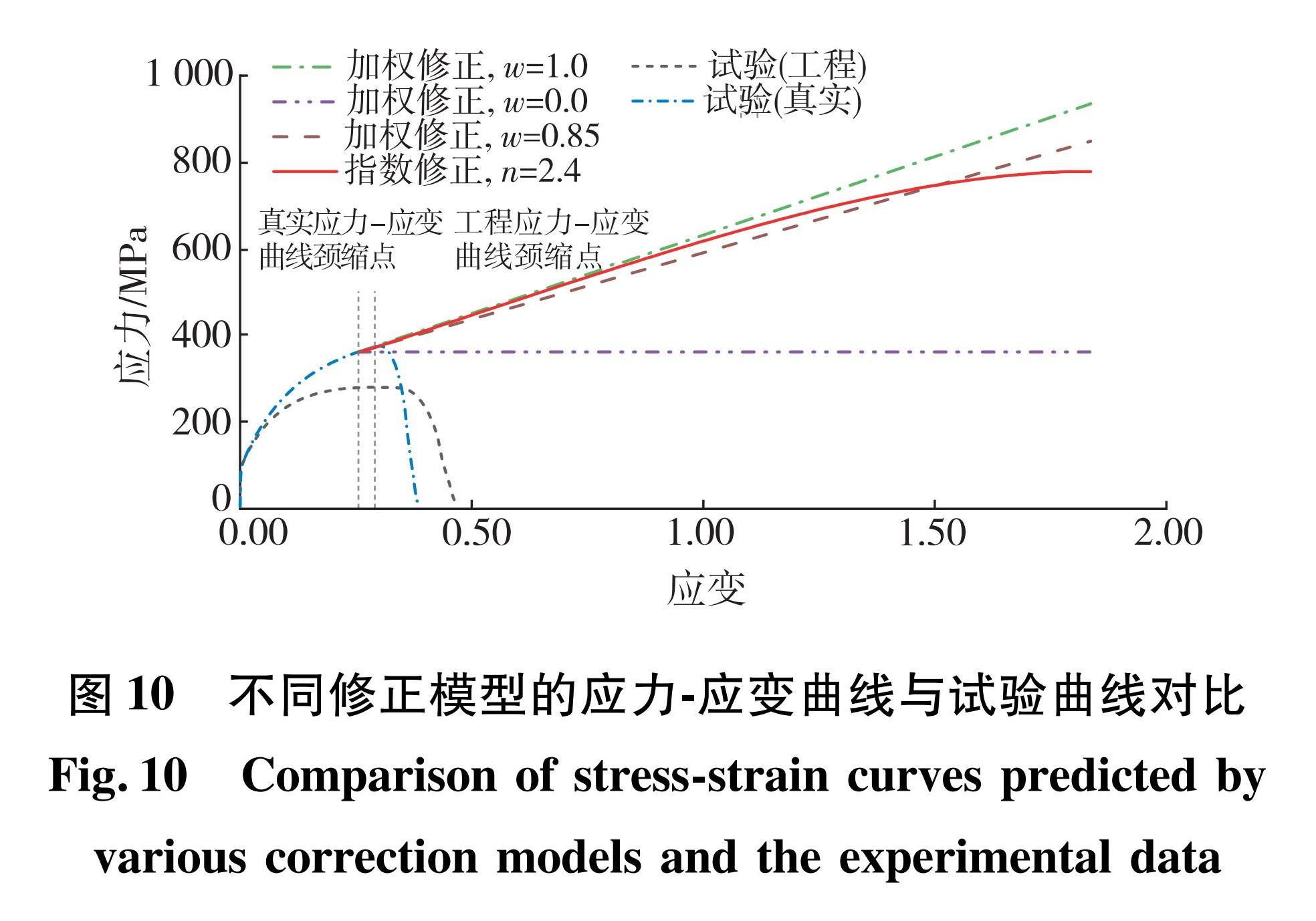

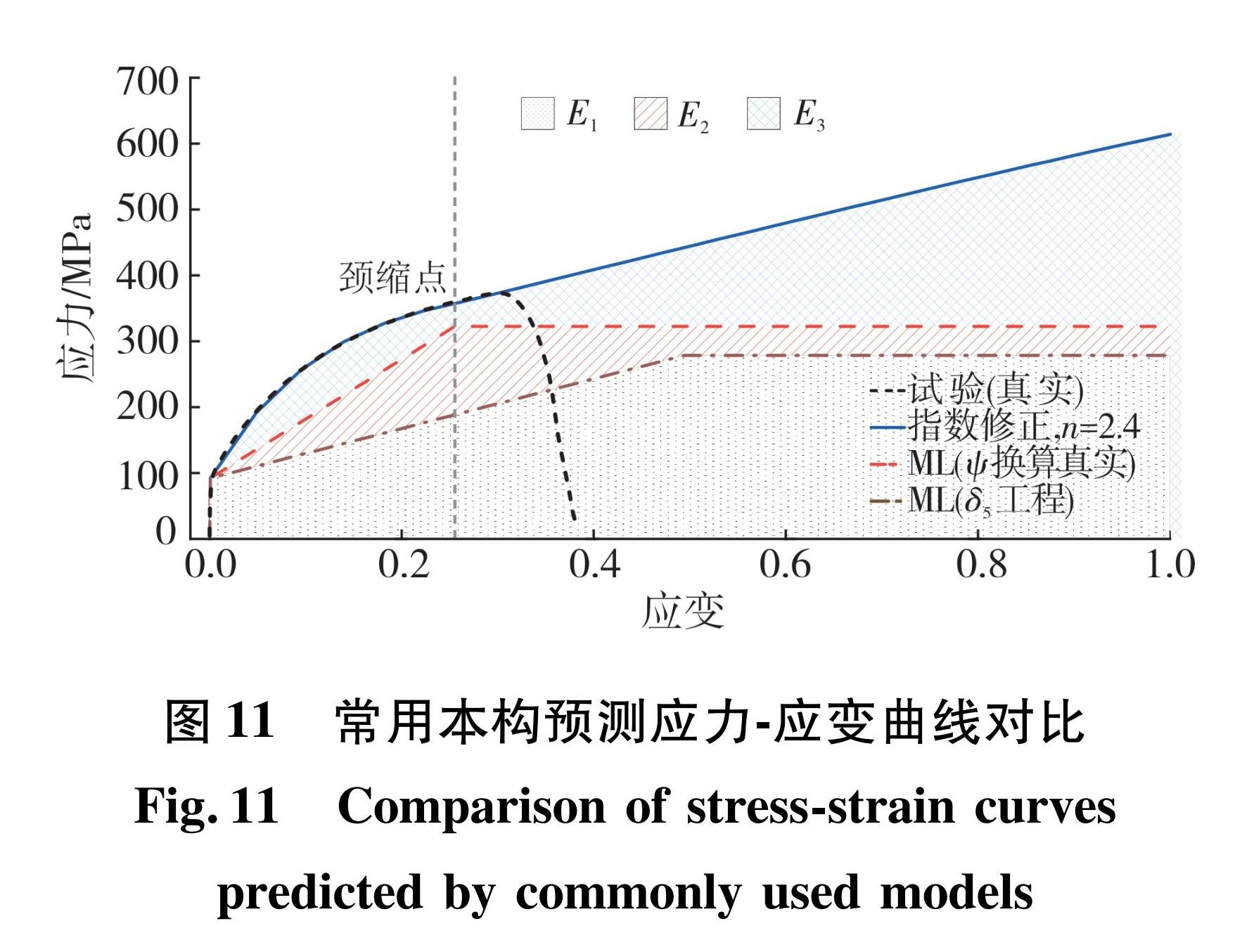

4.4 本构行为对比通过独立单元的加载测试,得到加权修正和指数修正方法预测的应力-应变曲线如图 10所示,采用w=0.85的加权修正和n=2.4的指数修正方法在50%应变以下效果相似,但在大应变域存在显著的趋势差异。延性金属结构的塑性失稳失效一般源于应变集中导致的大塑性变形,而指数修正的硬化模量渐进于0的假设很好地反映了该失效过程。此外,图 11中对比了指数修正和工程常用本构的应力-应变曲线,从曲线下面积(即拉伸韧度)可知,指数修正可充分考虑材料真实承载能力,有利于结构的轻量化设计。

图 10 不同修正模型的应力-应变曲线与试验曲线对比

Fig.10 Comparison of stress-strain curves predicted by various correction models and the experimental data5 结论

液体火箭发动机中广泛采用延性铜合金材料,而由于无法有效处理拉伸试验颈缩后数据,传统工程强度分析所用材料本构无法充分反映其真实承载能力。本文针对某延性铜合金开展常温单轴拉伸试验,并从工程强度分析的角度提出通用修正函数与参数拟合原则,随后通过有限元颈缩仿真拟合修正因子并说明方法的合理性,结论如下。

1)该延性铜合金具有较强的塑性变形能力,采用双线性关系描述其大应变域响应时对结构承载能力评估误差较大,而试验真实应力-应变数据仅在颈缩段前有效。

2)指数修正方法可更好地描述铜合金试件颈缩后响应,选取n=2.4可得到偏保守的性能估计。

本文研究为延性铜合金结构的承载能力评估及与延性耗竭相关失效行为的分析提供了理论基础,进一步研究可将该方法拓展应用于铜合金在不同温度下的颈缩后行为修正,以及大应变域内的循环应力-应变行为修正。

- [1] ANTOLOVICH S D, ARMSTRONG R W. Plastic strain localization in metals: origins and consequences[J]. Progress in Materials Science, 2014, 59(1): 1-160.

- [2]BORJA R. A finite element model for strain localization analysis of strongly discontinuous fields based on standard Galerkin approximation[J]. Computer Methods in Applied Mechanics and Engineering, 2000, 190(11/12): 1529-1549.

- [3]ZHU Y Z, KANVINDE A, PAN Z F. Analysis of post-necking behavior in structural steels using a one-dimensional nonlocal model[J]. Engineering Structures, 2019, 180: 321-331.

- [4]DOWLING N E. Mechanical behaviour of materials[M]. New Jersey: Pearson Education, Inc, 2013.

- [5]BRIDGMAN P. The stress distribution at the neck of a tension specimen[J]. Trans. ASM, 1944, 32:553-574.

- [6]BRIDGMAN P. Studies in large plastic flow and fracture[M]. New York: McGraw-Hill, 1952.

- [7]DAVIDENKOV W. Mechanical methods of testing analysis of the state of stress in the neck of a tension specimen[C]//Proceedings of the ASTM. [S.l.]:ASTM, 1946.

- [8]SIEBEL E, SCHWAIGERE S. Mechanics of tensile test[J]. Arch. Eisenhuttenwes, 1948, 19:145-152.

- [9]SHAHRJERDI A, RANJBAR B. Correction of post-necking stress-strain curve of copper using surface strain method[J]. Archive of Applied Mechanics, 2022, 92(1): 199-219.

- [10]ZHUANG X C, ZHAO Z, LI H Y, et al. Experimental methodology for obtaining the flow curve of sheet materials in a wide range of strains[J]. Steel Research International, 2013, 84(2): 146-154.

- [11]JOUN M, EOM J G, LEE M C. A new method for acquiring true stress-strain curves over a large range of strains using a tensile test and finite element method[J]. Mechanics of Materials, 2008, 40(7): 586-593.

- [12]ZHU F P, BAI P X, ZHANG J B, et al. Measurement of true stress-strain curves and evolution of plastic zone of low carbon steel under uniaxial tension using digital image correlation[J]. Optics and Lasers in Engineering, 2015, 65: 81-88.

- [13]LING Y. Uniaxial true stress-strain after necking[J]. AMP Journal of Technology, 1996, 5:37-48.

- [14]JIA L J, KUWAMURA H. Ductile fracture simulation of structural steels under monotonic tension[J]. Journal of Structural Engineering, 2014, 140(5): 04013115.

- [15]GAO Y S, ZHANG P, HUO S H. An investigation on the cyclic deformation and service life of a reusable liquid rocket engine thrust chamber wall[J]. Multidiscipline Modeling in Materials and Structures, 2023, 19(3): 522-543.

- [16]张凭, 李斌, 高玉闪,等. 重复使用火箭发动机推力室疲劳分析研究进展[J].火箭推进,2024,50(1):12-27.

- [17]中国钢铁工业协会. 金属-材料 拉伸试验 第1 部分:室温试验方法:GB/T 228.1-2021[S]. 北京:中国标准出版社,2021.

- [18]KALPAKJIAN S. Manufacturing engineering and technology[M]. Hoboken: Pearson Education, Inc, 2006.

- [19]贾良玖, 葛汉彬. 强震下金属结构的超低周疲劳破坏[M]. 上海: 同济大学出版社, 2019.