作者简介:夏爽(1997—),女,硕士,研究领域为液体火箭发动机试验。

1.北京航空航天大学 宇航学院,北京 102206; 2.北京航天试验技术研究所,北京 100074; 3.贵州航天朝阳科技有限责任公司,贵州 遵义 563000

1.School of Astronautics, Beijing University of Aeronautics and Astronautics, Beijing 102206, China; 2.Beijing Institute of Aerospace Testing Technology, Beijing 100074, China; 3.Guizhou Aerospace Zhaoyang Science and Technology Co., Ltd., Zunyi 563000, C

steam ejection; boiler; accumulator; steam supply system; high altitude simulation test

DOI: 10.3969/j.issn.1672-9374.2024.02.015

备注

作者简介:夏爽(1997—),女,硕士,研究领域为液体火箭发动机试验。

引言

随着航空航天试验技术的不断发展,对于高空性能要求较为严格的航空航天发动机,都会进行高空模拟试验(简称高模试验)来获得其实际性能。目前国内外广泛采用蒸汽引射式高模试验台,比如美国的In-Space Propulsion Facility、德国的Test Bench P4.1及国内的GS-1和GS-2等高模试验台[1]。蒸汽引射式高模试验台利用蒸汽作为抽气工质,高速燃气在扩压器中减速增压后经抽气系统排出。

高模试验台蒸汽引射需要消耗大量蒸汽,对于不同的试验推力、模拟高度、试验时间、试验对象以及技术成熟度,高模试验台蒸汽引射所用的蒸汽供应系统(供汽系统)也会不同,供汽系统可以采用锅炉供汽、锅炉-蓄热器式供汽系统以及燃气发生器,对于短时大流量蒸汽引射用汽需求,一般采用锅炉-蓄热器式供汽系统。

锅炉技术发展至今已较为成熟,在电力和化工行业应用极为广泛,比如电站锅炉供应蒸汽驱动汽轮机做功发电[2]及化工行业中空分装置采用锅炉供汽驱动涡轮[3],锅炉直接供应蒸汽适用于需要长时间连续运行的工程项目。国内外有较多关于蒸汽引射用燃气发生器的应用和研究,美国AFRPL和德国DFVLR的高模试验台蒸汽引射用供汽系统采用的就是燃气发生器[4],国内试验研究机构在文献[5]和文献[6]中针对蒸汽引射所用燃气发生器做了一系列研究工作。

锅炉-蓄热器系统用于热能储存始于19世纪末[7],主要目的在于平衡锅炉负荷波动,广泛应用于工业生产制造、钢铁冶金、电厂和船舶等行业[8-11]。锅炉-蓄热器系统通常采用小型工业蒸汽锅炉,为提高热效率及减少排放污染,目前工业蒸汽锅炉一般为燃油燃气锅炉,锅炉常用的热力计算标准为苏联公开的1973年版本[12]及在此基础上发展而来的其他方法。我国从国外引入蒸汽蓄热器技术后,在20世纪60年代也开始自行设计制造,之后中国船舶工业总公司第九设计研究院开始对其进行研究,整理出了蒸汽蓄热器的设计方法[13-14]。蒸汽蓄热器是以水为载热体间接储蓄蒸汽的蓄热装置,通过降压闪蒸产生蒸汽,可作为用汽负荷波动大、汽源间断供汽和瞬时耗汽量极大等用汽条件下的供汽设备。对于高模试验台在短时间应用大量蒸汽进行引射的场合,采用容量不大的锅炉配以足够容量的蒸汽蓄热器储存热量,就可以在短时间内提供大量的高温高压蒸汽。文献[15-18]通过仿真和实验研究得到了舰载机蒸汽弹射所用锅炉-蓄热器系统的动态特性。文献[19-20]对蒸汽蓄热器充放汽过程做了大量研究,并将所建立模型应用于煤炭干燥厂蒸汽锅炉和高压灭菌器之间蒸汽蓄热器的仿真分析,该团队还论证了蒸汽蓄热器对火电厂负荷频繁变化情况下供汽灵活性有提升作用[10]。

尽管锅炉-蓄热器式供汽方式已经广泛应用于航天领域的高模试验,如法国的MESA试验台,美国的J-3试验台和J-4试验台[4],但国内外几乎没有关于高模试验台所用锅炉-蓄热器式供汽系统设计方法的公开文献报道。锅炉-蓄热器式供汽系统是一种子系统工作过程复杂且子系统之间相互耦合的大型蒸汽供应设备,系统设计有其特殊性和复杂性。针对短时大流量蒸汽引射式高模试验台,考虑到锅炉-蓄热器式供汽系统的运行状况对采用该系统供汽的高模试验台性能有重大影响,本文就锅炉-蓄热器式供汽系统的方案设计方法和流程进行研究,并进行案例设计和验证试验,为类似工况下锅炉-蓄热器式供汽系统的设计提供参考。

1 供汽系统方案设计

2 案例设计

针对某液体姿轨控发动机蒸汽引射式高模试验台短时间大量耗汽的实际应用需求,采用锅炉-蓄热器式供汽系统作为蒸汽发生装置,按照前述设计方法和流程,以饱和蒸汽为引射介质进行锅炉-蓄热器式供汽系统方案设计。本方案设计了两条完全相同的并列式放汽管路,可以单路放汽也可以双路同时放汽,以便针对试验发动机推力的大小合理利用蒸汽进行引射。

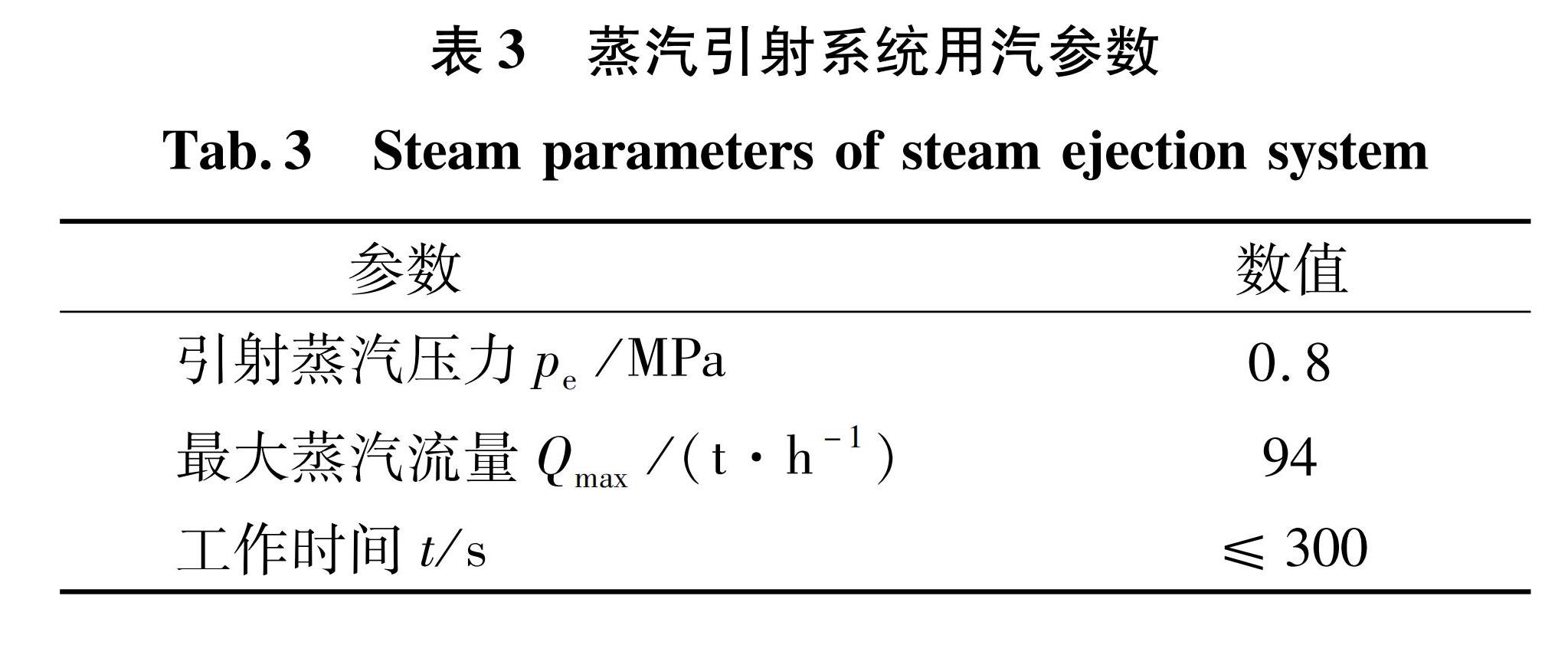

2.1 性能与结构设计通过高模试验台蒸汽引射器用汽要求,得到如表3所示的蒸汽参数。

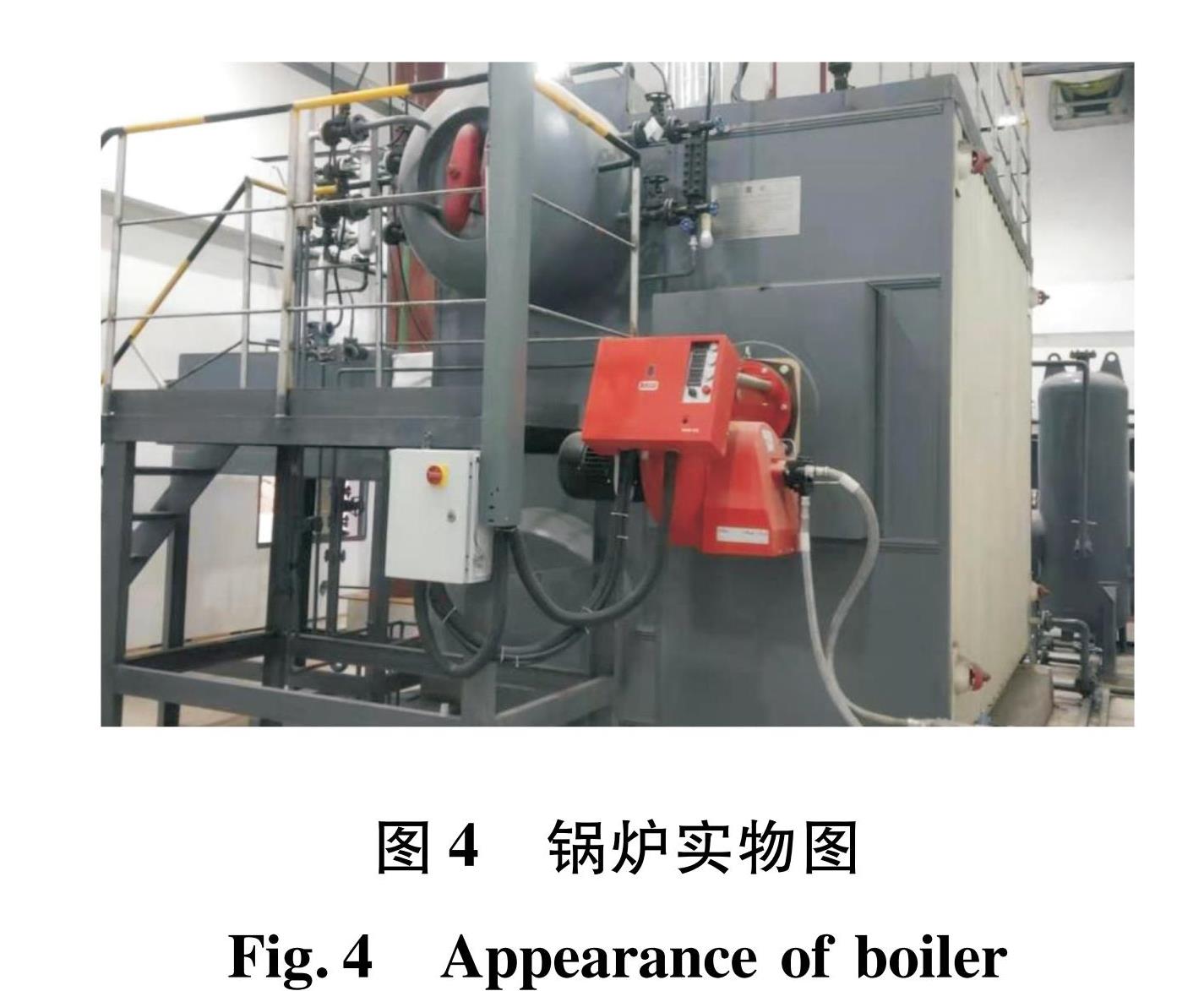

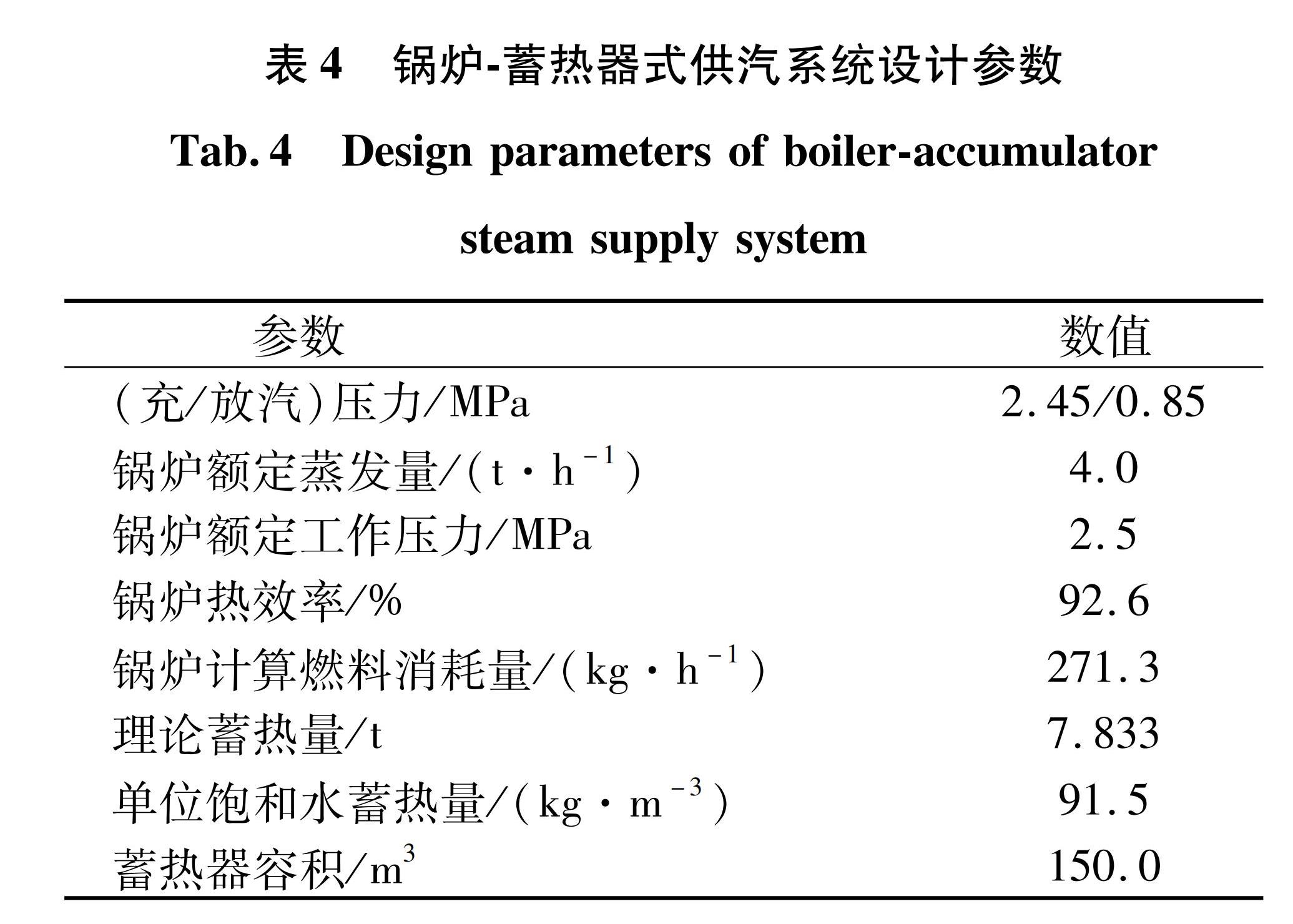

蒸汽管道压降初步取值0.05 MPa进行计算,根据引射蒸汽压力,可以初步确定放汽压力为0.85 MPa。充汽压力还需要结合锅炉额定工作压力来确定,按照标准规格系列选用额定蒸发量为4 t/h、额定工作压力为2.50 MPa的饱和蒸汽锅炉,由此可以初步确定充汽压力为2.45 MPa。试验用锅炉采用泰山集团生产的SZS型双锅筒纵置式燃油蒸汽锅炉,燃料为0号轻柴油,锅炉燃烧机为意大利百利P450 T/G,燃烧机火力有3个档位(小火/中火/大火),锅炉实物图见图4。

按式(3)~式(5)可计算得到蓄热器理论蓄热量、蓄热器容积及单位饱和水蓄热量(计算理论蓄热量时假定锅炉停炉,即蒸发量为0 t/h),蓄热器效率取90%且充水系数取70%时,可计算得到蓄热器理论容积为136 m3,结合规格系列选取150 m3的蓄热器,试验用蓄热器为卧式蒸汽蓄热器,实物见图5。

锅炉至蓄热器及蓄热器至引射器之间通过蒸汽管道连接,结合现场安装环境进行蒸汽管道设计计算。蒸汽流速取值20 m/s,充汽时阀门全开工作,放汽时单条管道放汽流量为47 t/h。结合现场布局进行蒸汽管道的流阻损失计算可得:锅炉至蓄热器蒸汽管道直径80 mm,蒸汽管道总长38 m,总管路流阻23 kPa; 蓄热器至引射器蒸汽管道直径400 mm,蒸汽管道总长80 m,总管路流阻12 kPa。通过管道流阻计算可得到充放汽蒸汽管道流阻与初始取值偏差在允许范围以内,故充放汽压力、锅炉和蓄热器工作压力能满足工作需求。蒸汽管道和蓄热器筒体外部包覆硅酸铝保温层,并在外层裹上镀锌铁皮。

锅炉-蓄热器式供汽系统性能与结构主要设计参数见表4,系统中受压元件用钢板材料采用Q345R,钢管材料采用Q245R。

3 方案设计验证试验

4 结论

通过对短时间大流量蒸汽引射用供汽系统方案设计的研究,得到以下主要结论。

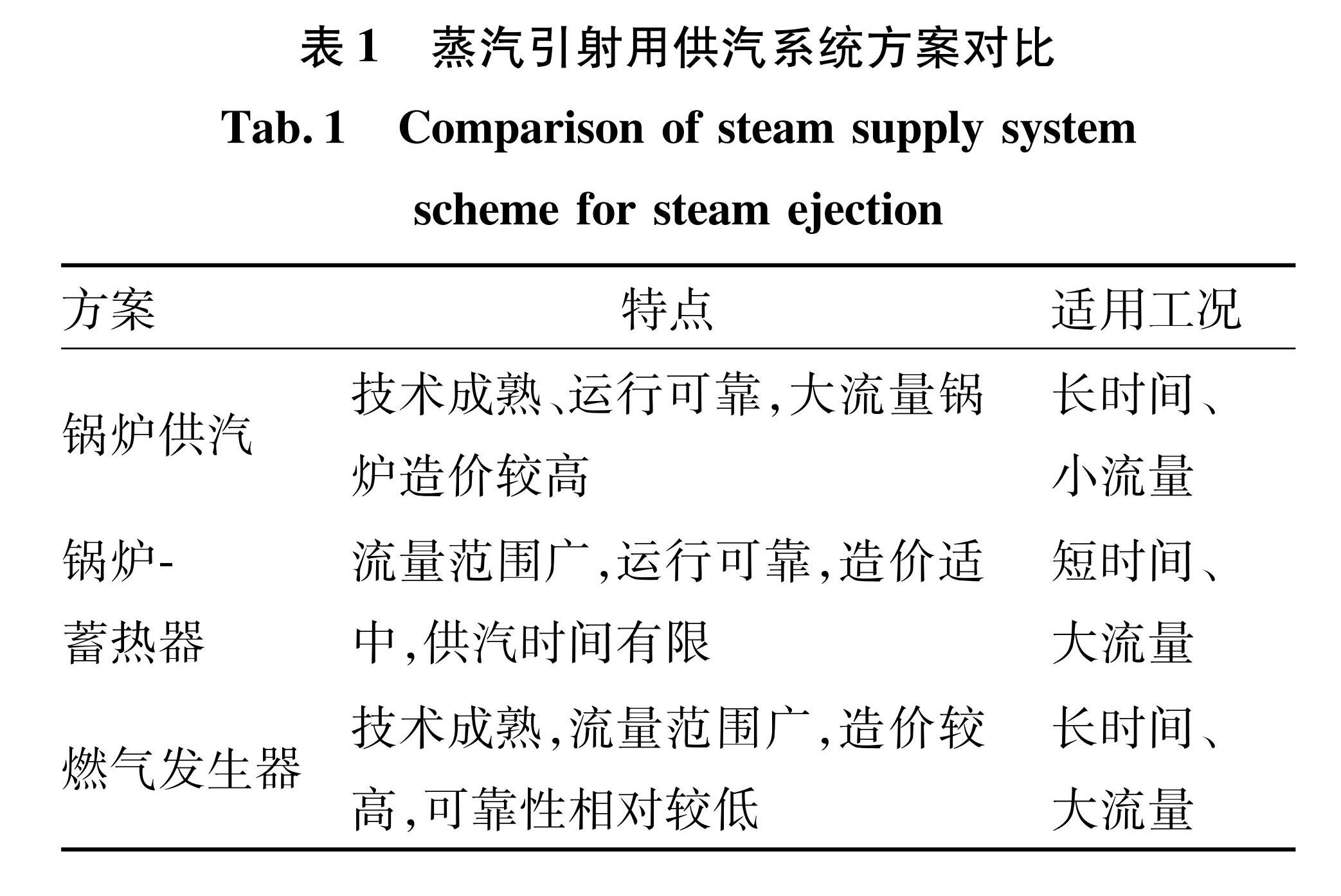

1)从蒸汽引射系统用汽需求出发,对3种供汽系统方案进行对比,针对短时大流量蒸汽引射,推荐采用锅炉-蓄热器式供汽系统。

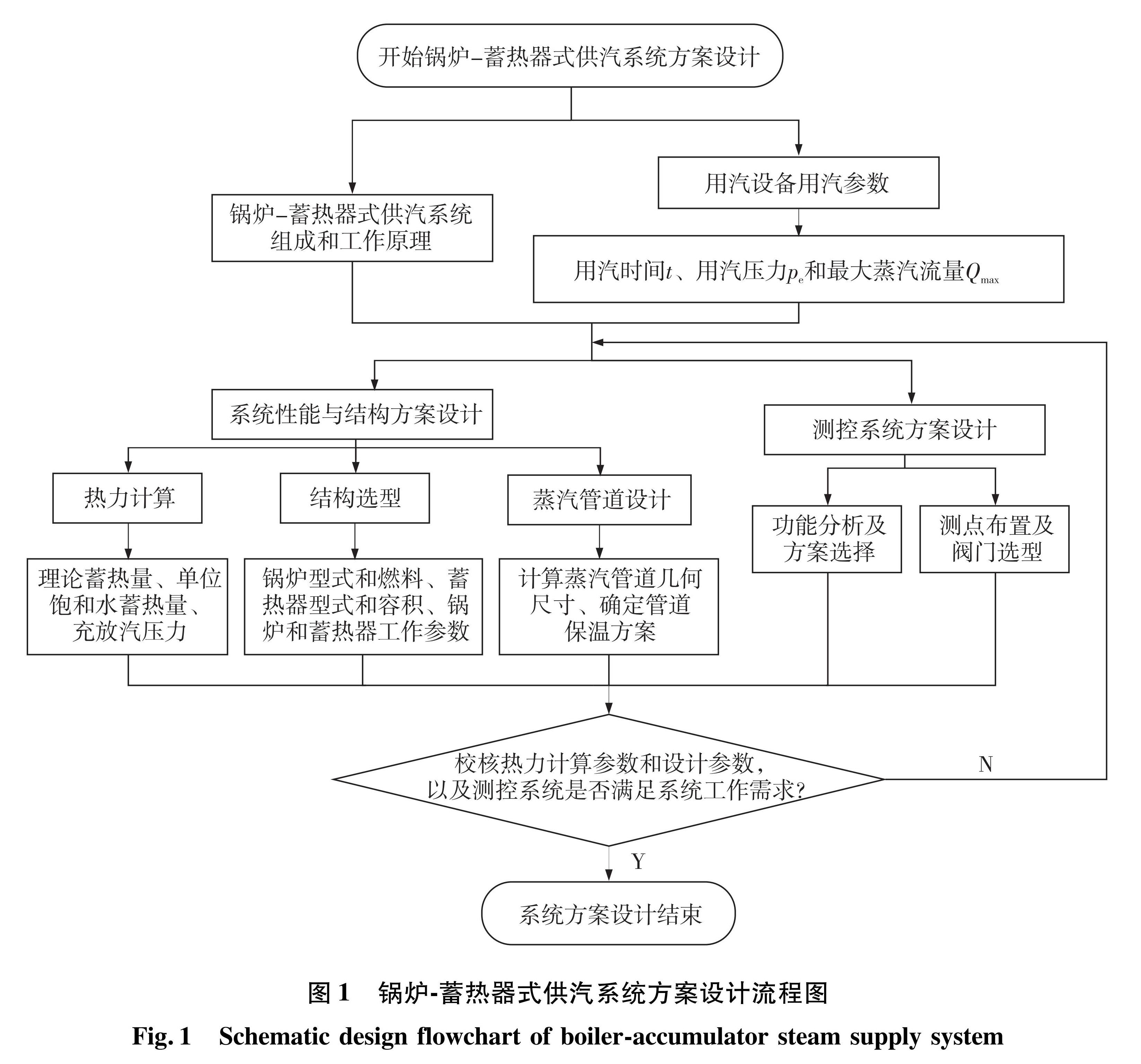

2)提出适用于短时大流量用汽需求的锅炉-蓄热器式供汽系统的组成方案和工作原理,给出了锅炉-蓄热器式供汽系统方案设计方法和流程,提供了更加符合工程应用的锅炉、蓄热器、阀门等重要设备的选型依据。

3)以某液体姿轨控发动机高模试验台蒸汽引射用供汽系统为案例,采用锅炉-蓄热器式供汽系统进行方案设计,并通过试验验证了该方案设计方法和流程应用于工程实际的可行性。

4)试验验证了案例锅炉-蓄热器式供汽系统充汽过程、保温过程和放汽过程性能均良好,蓄热器在高水位工况下充汽速率较慢但保温性能较好,放汽过程阀后压力能稳定在设定值并且两条放汽路一致性较好。

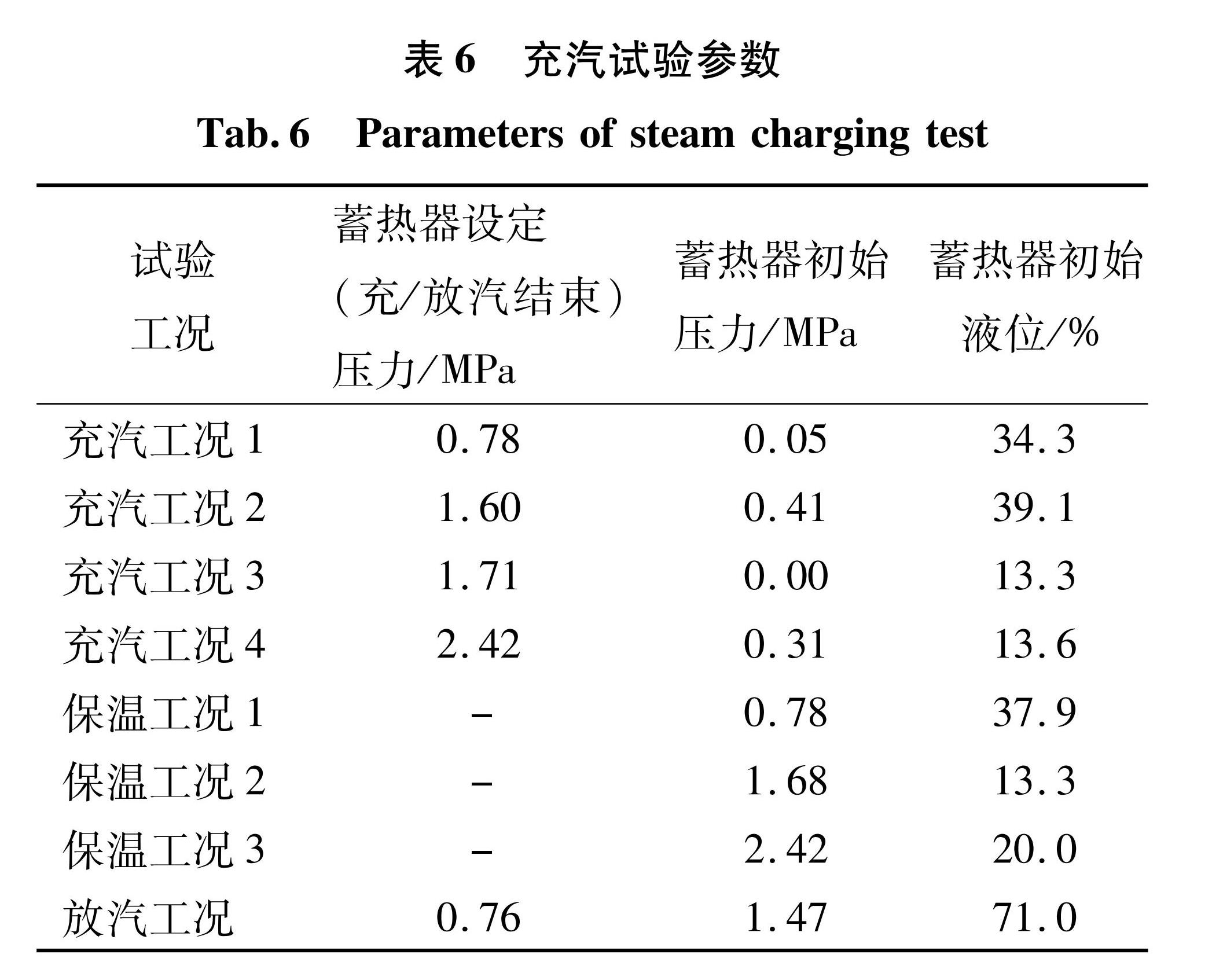

3.1 试验过程为验证锅炉-蓄热器供汽系统实际案例的工作性能,采用案例系统进行充汽试验、保温试验和放汽试验,试验工况参数见表6(本文有关试验部分所有压力数据均为表压)。

充汽试验前锅炉用小火启炉,待锅炉运行稳定后再打开阀门向蓄热器充汽。稳定运行期间,充汽工况1、充汽工况2和充汽工况3锅炉中火运行,充汽工况4锅炉小火运行(锅炉火力越大,对应的充汽流量越大)。冷态充汽时,要对蒸汽管道进行预热,控制锅炉出口蒸汽阀门开度不要过大,待蓄热器内部温度开始上升后可逐步调大阀门开度。锅炉向不同初始水位下的蓄热器分别充汽至设定压力,蓄热器压力达到设定值后锅炉停炉,关闭蓄热器进口蒸汽阀门。为检测蓄热器在设计工作压力下的性能,在充汽试验工况4下第一次充汽至2.4 MPa停止充汽后,待压力下降至2.0 MPa再反复两次充汽至2.4 MPa。

保温试验是在蓄热器充汽结束后充放汽阀门均关闭的情况下,通过一段时间内蓄热器压力和温度的变化量来测试蓄热器保温效果。

放汽试验开始前要等待下游引射器完成放汽前准备工作,之后使用锅炉蒸汽通过预热管道对下游放汽管道进行预热,然后蓄热器出口放汽闸阀和调节阀依次打开进行放汽,通过控制放汽调节阀开度来控制阀后压力稳定在0.75 MPa左右,放汽结束时先关闭放汽闸阀后关调节阀。放汽试验单路放汽管路放汽流量为47 t/h,此次放汽试验进行了双路放汽管路放汽。

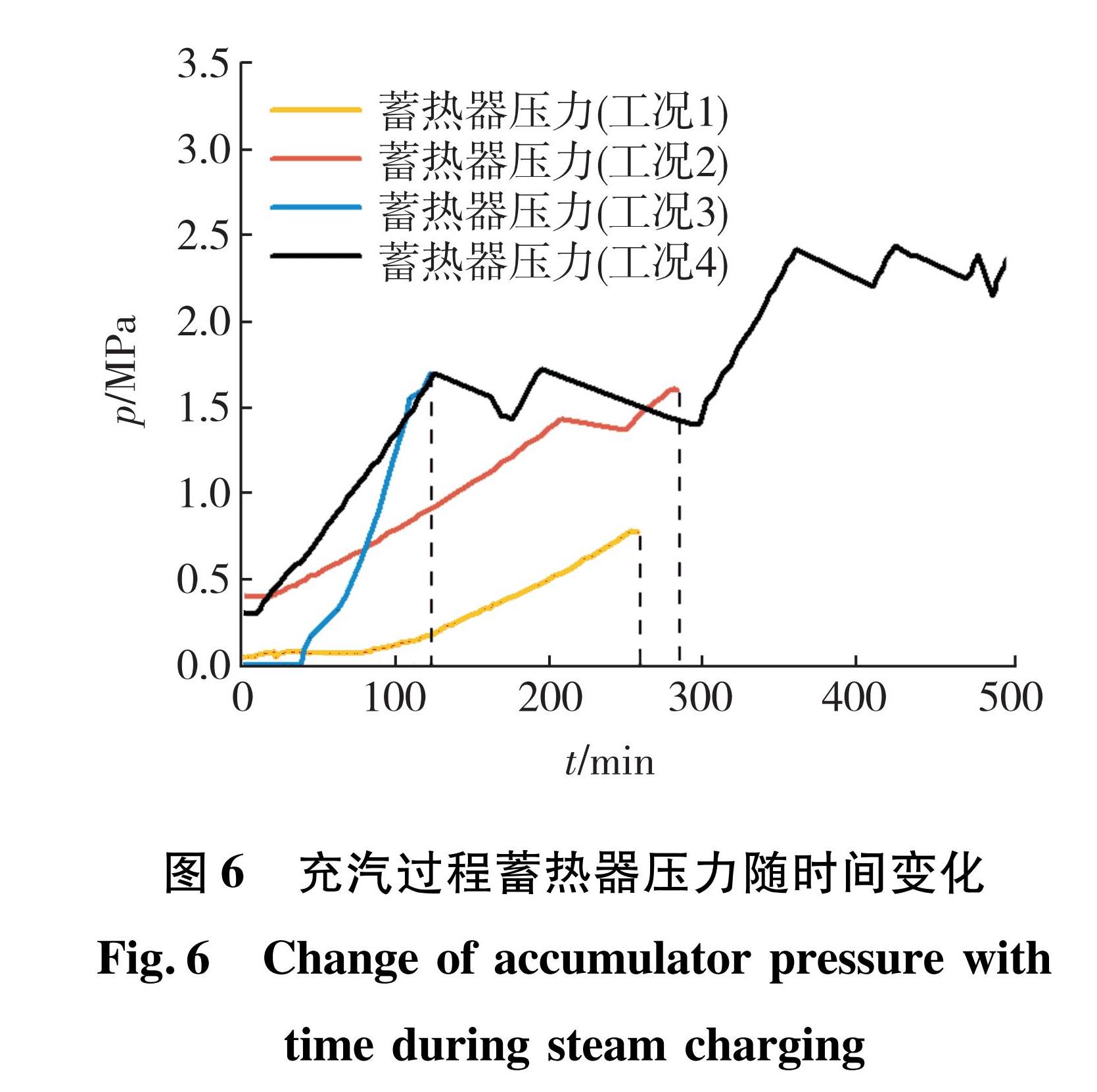

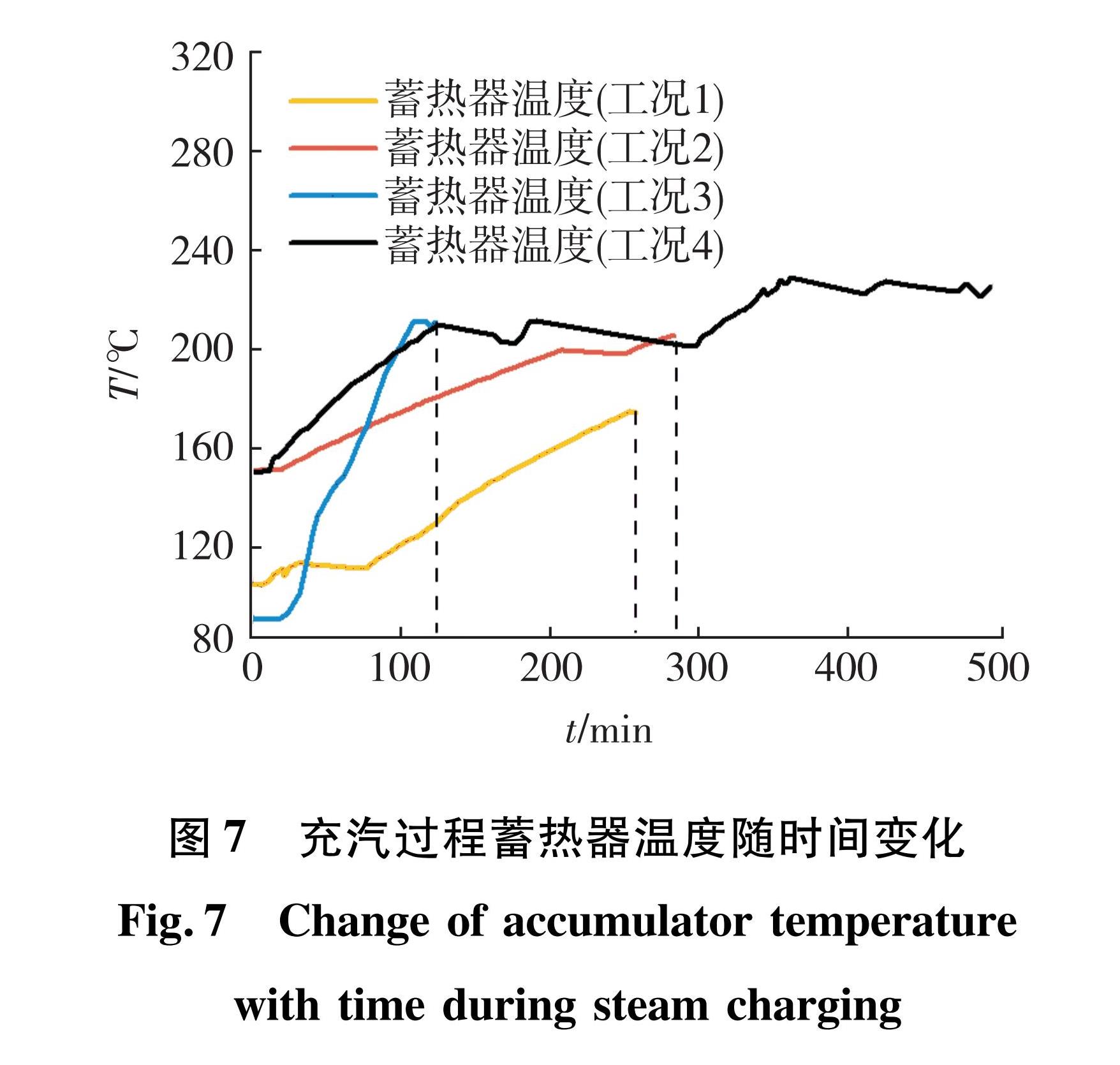

3.2 试验结果及分析3.2.1 充汽试验案例锅炉-蓄热器式供汽系统充汽过程蓄热器压力和温度随时间变化见图6和图7。

其中曲线多处出现突降点,是由于实际试验过程人员离岗锅炉停炉所致。充汽试验结果表明:案例系统能正常充汽至设定压力,系统充汽过程工作性能良好; 高水位工况(工况1、工况2)充汽速率较慢。详细的试验分析见文献[26]。

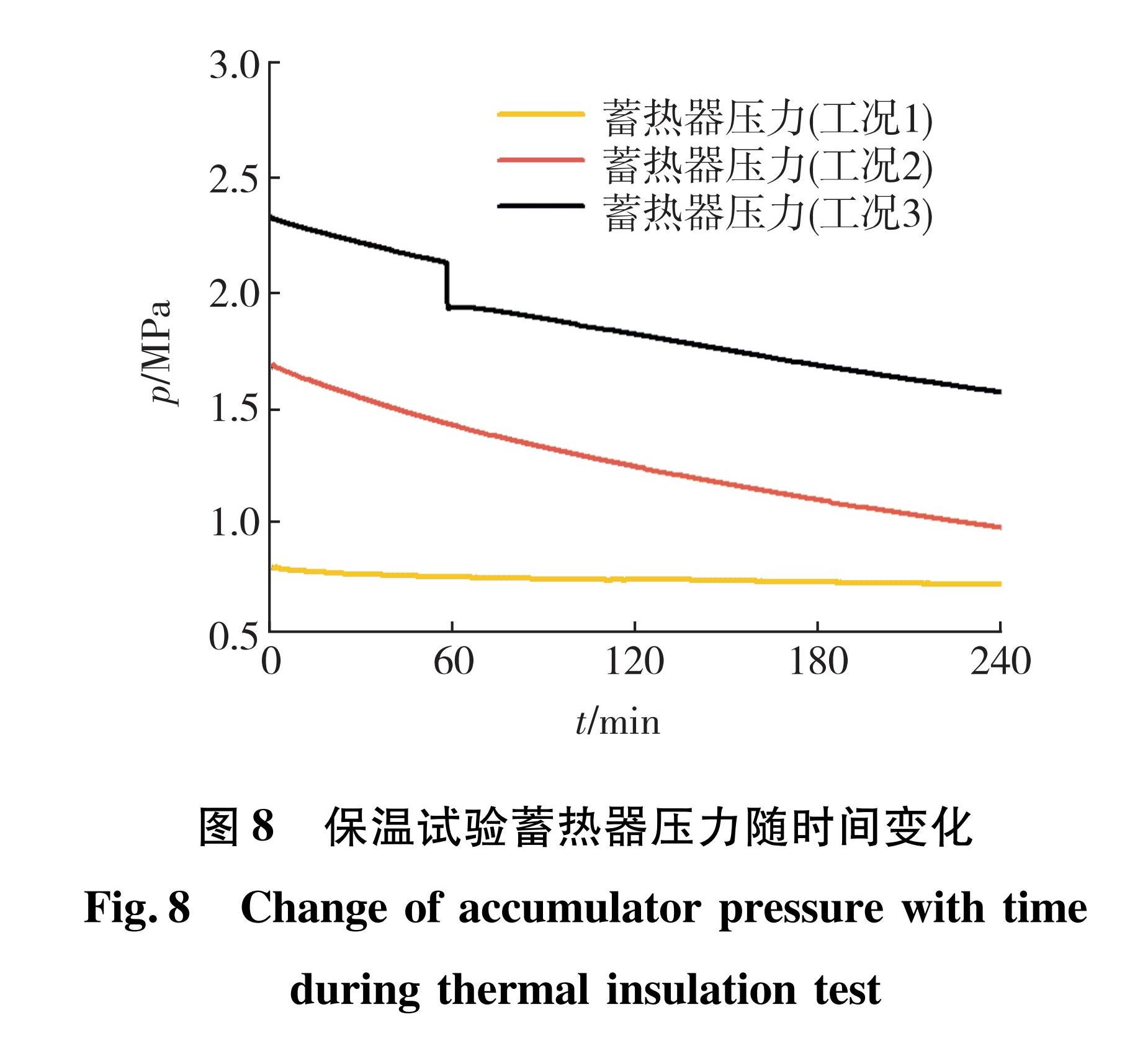

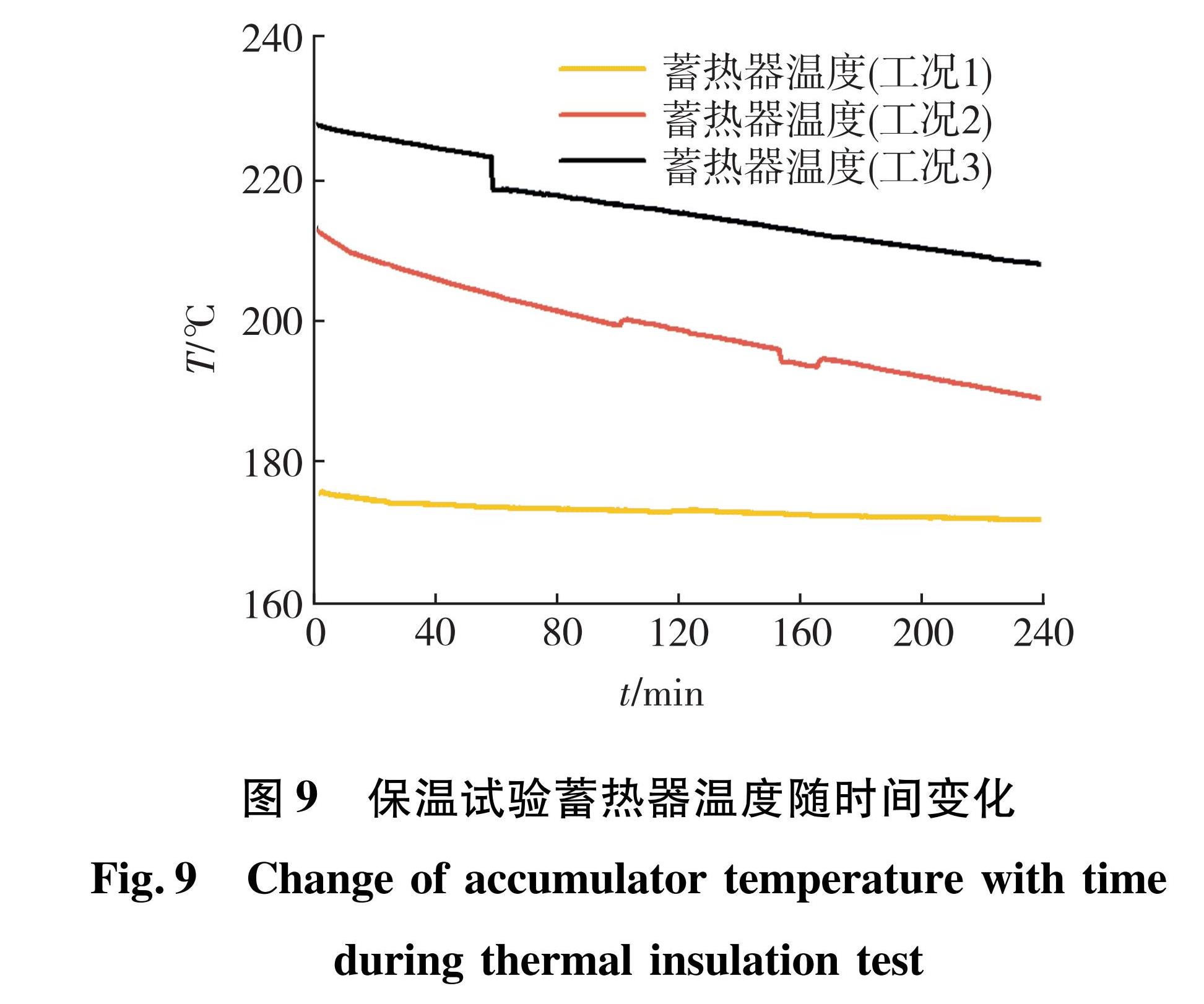

3.2.2 保温试验在蓄热器充汽至设定压力后,关闭充汽阀门对蓄热器保温性能进行测试。图8和图9是蓄热器4 h保温试验压力和温度随时间的变化曲线。

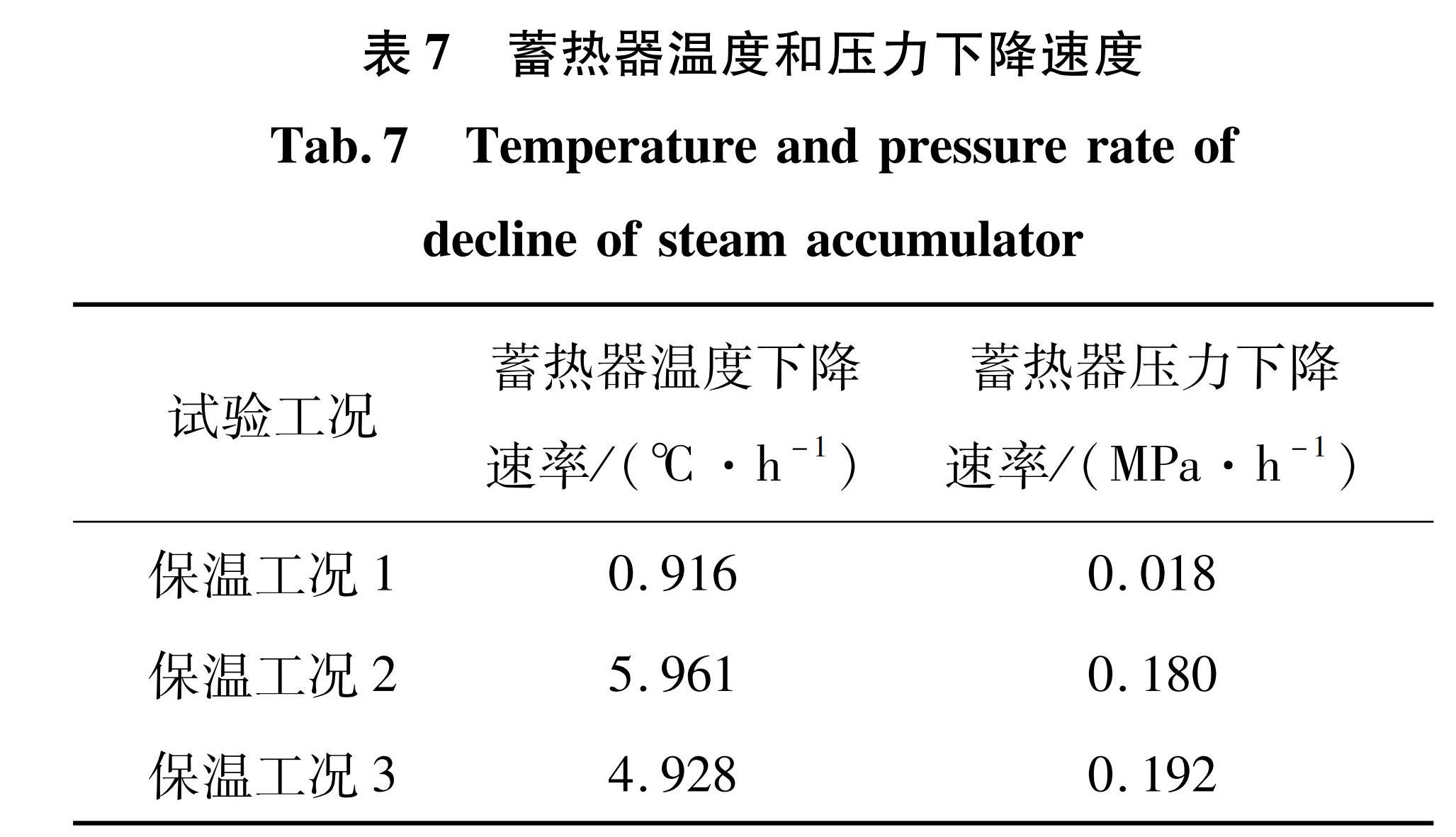

3种工况下蓄热器温度和压力均缓慢下降,蓄热器保温性能良好,蓄热器保温测试过程4 h下降速率见表7。

其中工况1温度和压力下降速度明显低于工况2和工况3,故高水位工况下保温效果较好。

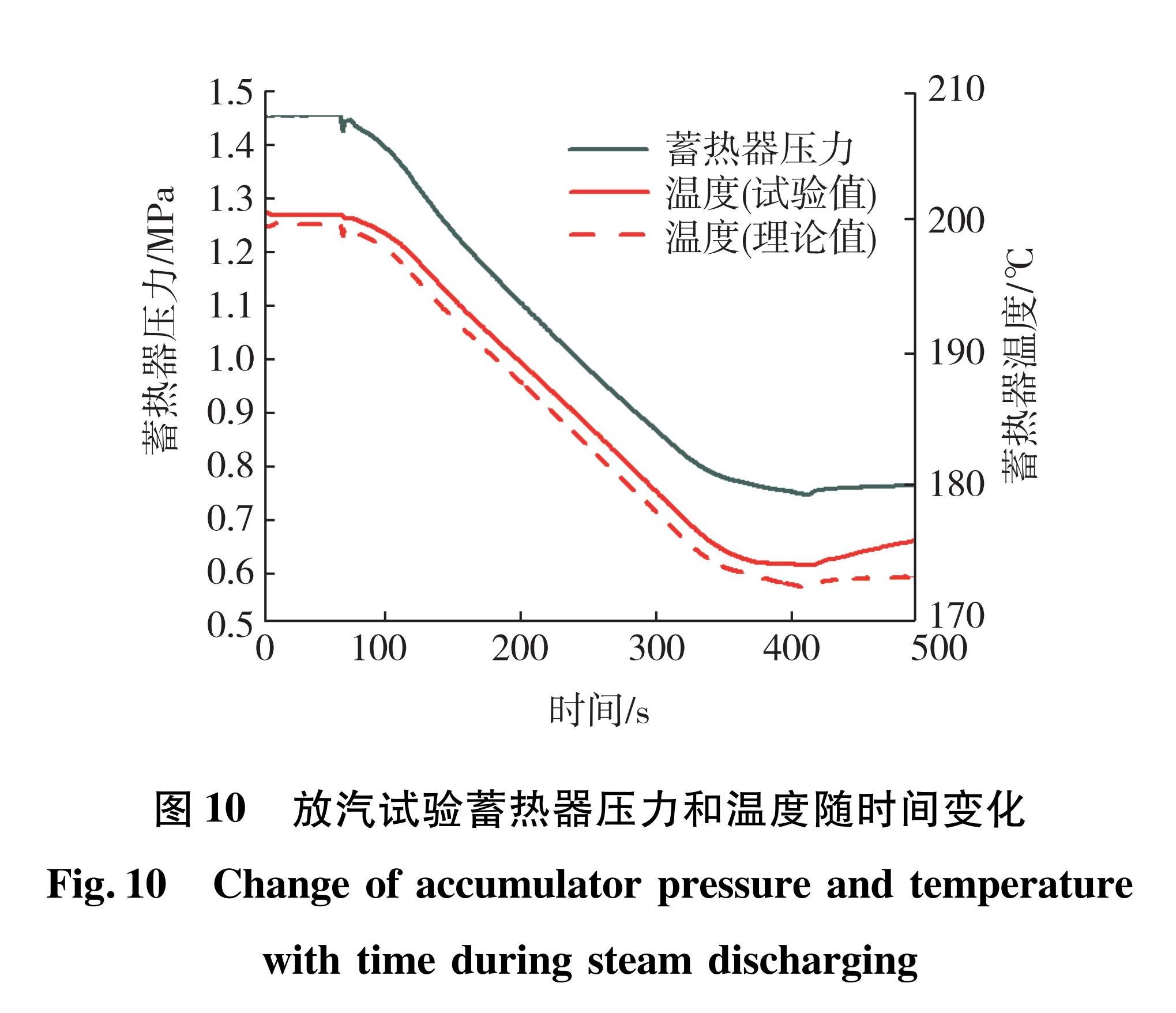

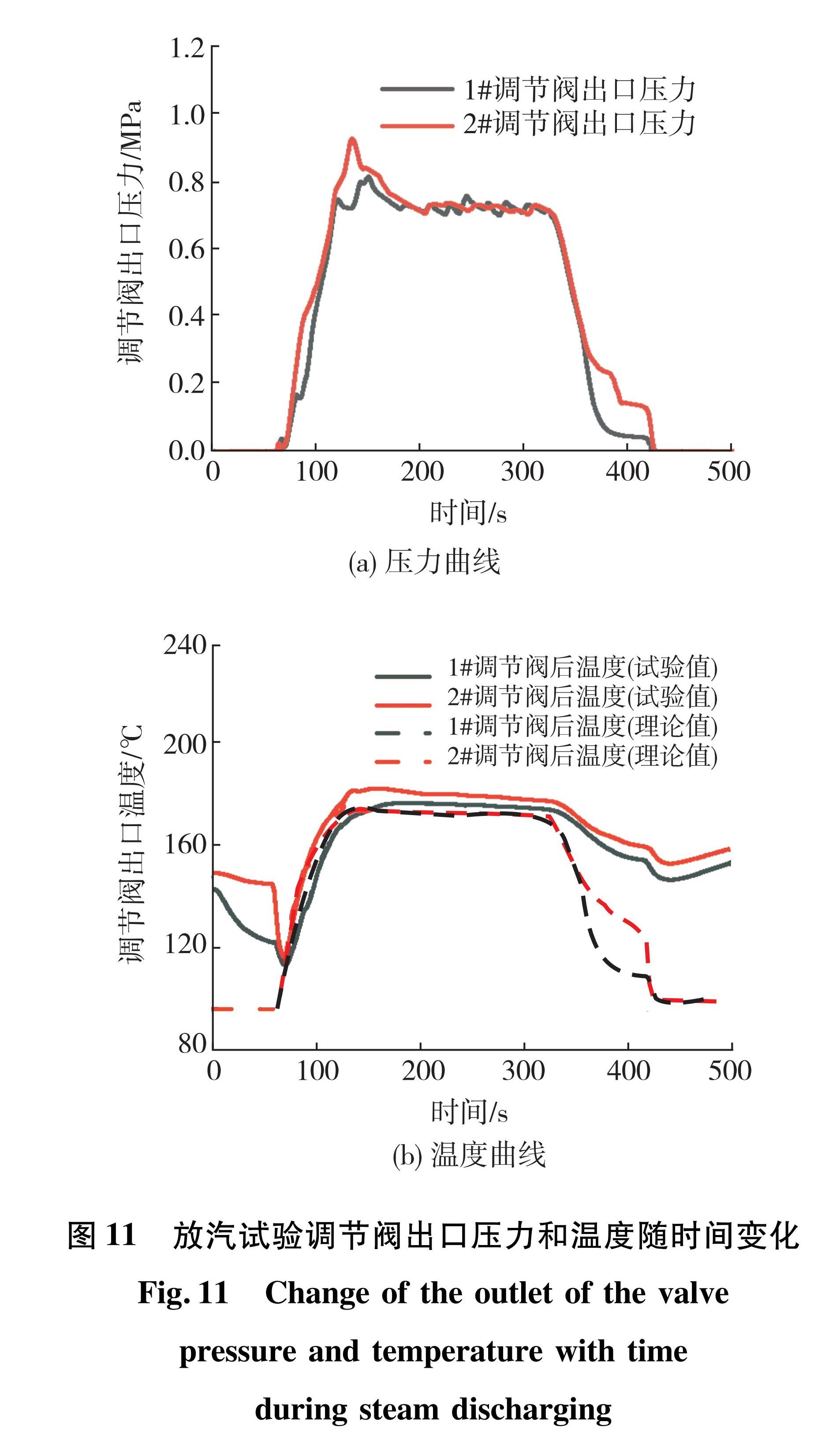

3.2.3 放汽试验按照设定的放汽工况进行锅炉-蓄热器式供汽系统放汽试验,放汽过程蓄热器压力和温度变化曲线见图 10,两路放汽调节阀出口压力和温度变化曲线见图 11。

图 10 放汽试验蓄热器压力和温度随时间变化

Fig.10 Change of accumulator pressure and temperature with time during steam discharging从图 10和图 11可以看出,放汽过程蓄热器落压工作,放汽试验稳定段调节阀后压力稳定在0.75 MPa左右,满足下游引射器用汽需求,锅炉-蓄热器式供汽系统的放汽性能良好。图中红色虚线为理论温度参数,是用IAPWS_IF97公式计算测得的压力数据所对应的饱和温度,从曲线可以看出放汽过程蒸汽有一定的过热度。放汽结束后蓄热器压力和温度曲线还有一个小幅度的回升,这是由于传感器均布置在蓄热器汽空间,而蓄热器内液空间热惯性会导致水继续蒸发使汽空间压力和温度上升。放汽调节阀后温度在放汽前初始温度较高,是因为放汽前会用锅炉蒸汽通过预热管道进行放汽管路的预热; 而放汽结束后温度的回升是由于放汽阀关闭后压力迅速下降,此时由于管道中残留的蒸汽会冷凝放热等因素导致温度回升。放汽初期调节阀后压力出现压力峰,是由于手动调节时超调所致。

- [1] 徐勇, 郭红杰, 超力德, 等.现役典型液体火箭发动机高空模拟试验系统技术特点分析[C]//第六届空天动力联合会议暨中国航天第三专业信息网第四十二届技术交流会暨2021航空发动机技术发展高层论坛论文集(第三册).成都:中国科协航空发动机产学联合体, 2022.

- [2]张力. 锅炉原理[M]. 北京: 机械工业出版社, 2011.

- [3] 田忠明, 查从念, 王伟, 等. 化工装置配套动力站锅炉主蒸汽压力等级选型研究[J]. 能源工程, 2013(4): 69-72.

- [4]DUCASSE P. Rocket altitude test facilities register[R]. France: advisory Group for Aerospace Research and Development, 1987.

- [5]孔凡超, 刘万龙, 胡旭坤, 等. 蒸汽发生器掺混工质对引射性能的影响分析[J]. 火箭推进, 2016, 42(1): 77-82.

- [6]赵宏, 张海栋, 孙小丽, 等. 大流量火箭蒸汽发生器试验研究[J]. 推进技术, 2013, 34(8): 1077-1081.

- [7]程祖虞. 蓄热器技术发展史概况[J]. 动力工程, 1984, 4(1): 13-20.

- [8] SUN W Q, HONG Y H, WANG Y H. Operation optimization of steam accumulators as thermal energy storage and buffer units[J]. Energies, 2016, 10(1): 17.

- [9]PRICE N. Steam accumulators provide uniform loads on boilers[J]. Chemical Engineering, 1982, 89(23): 131-135.

- [10]STEVANOVIC V D, PETROVIC M M, MILIVOJEVIC S, et al. Upgrade of the thermal power plant flexibility by the steam accumulator[J]. Energy Conversion and Management, 2020, 223: 113271.

- [11]胡继敏, 金家善, 严志腾. 船用蒸汽蓄热器快速充汽过程吸热特性的测量方法研究[J]. 船舶工程, 2012, 34(S2): 55-59.

- [12]КУЗНЕЦОВ Н В. 锅炉机组热力计算标准方法[M]. 北京锅炉厂设计科译. 北京: 机械工业出版社, 1976.

- [13]程祖虞. 蒸汽蓄热器的应用和设计[M]. 北京: 机械工业出版社, 1986.

- [14]程祖虞. 推广蒸汽蓄热器、节约能源[J]. 能源技术, 1982, 3(1): 53-59.

- [15]孙宝芝, 郭家敏, 雷雨, 等. 船用蒸汽蓄热器非平衡热力过程[J]. 化工学报, 2013, 64(S1): 59-65.

- [16]SUN B Z, GUO J M, LEI Y, et al. Simulation and verification of a non-equilibrium thermodynamic model for a steam catapult's steam accumulator[J]. International Journal of Heat and Mass Transfer, 2015, 85: 88-97.

- [17] 孙宝芝, 郭家敏, 史智俊, 等. 不同运行条件下船用蒸汽蓄热器的充汽特性[J]. 化工学报, 2015, 66(S2): 172-179.

- [18]于海涛, 李彦军, 张国磊, 等. 不同充放汽条件下的锅炉-蓄热器系统动态特性[J]. 化工学报, 2014, 65(S1): 130-137.

- [19]STEVANOVIC V D, MASLOVARIC B, PRICA S. Dynamics of steam accumulation[J]. Applied Thermal Engineering, 2012, 37: 73-79.

- [20]STEVANOVIC V D, PETROVIC M M, MILIVOJEVIC S, et al. Prediction and control of steam accumu-lation[J]. Heat Transfer Engineering, 2015, 36(5): 498-510.

- [21]国家质量监督检验检疫总局. 工业蒸汽锅炉参数系列: GB/T 1921—2004[S]. 北京: 中国标准出版社, 2004.

- [22]钟世环.管径选择: HG/T 20570.6—95[S]. 北京:中华人民共和国化学工业部,1996.

- [23]王新月. 气体动力学基础[M]. 西安: 西北工业大学出版社, 2006.

- [24]华绍曾,杨学宁. 实用流体阻力手册[M]. 北京: 国防工业出版社, 1985.

- [25]杨世忠, 邢丽娟. 调节阀流量特性分析及应用选择[J]. 阀门, 2006(5): 33-36.

- [26]夏爽,朱昊伟,梁国柱,等.高空模拟试验台锅炉-蓄热器系统充汽试验[C]//第七届空天动力联合会议暨中国航天第三专业信息网第43届技术交流会论文集(第二册). 苏州:中国航天第三专业信息网, 2023.

1.1 供汽系统方案选择针对蒸汽引射所用的供汽系统,可采取锅炉供汽、锅炉-蓄热器式供汽系统及燃气发生器3种方案,方案对比情况见表1。通过供汽方案的对比分析,针对短时大流量蒸汽引射,本文采用锅炉-蓄热器式供汽系统。

锅炉-蓄热器式供汽系统方案设计流程见图1。根据高模试验台不同的试验推力、模拟高度、试验时间,引射系统会相应地给出用汽时间t、引射蒸汽压力pe和最大蒸汽流量Qmax这3个关键参数的具体要求,所以在进行具体设计计算之前,要先确定引射系统的用汽要求。

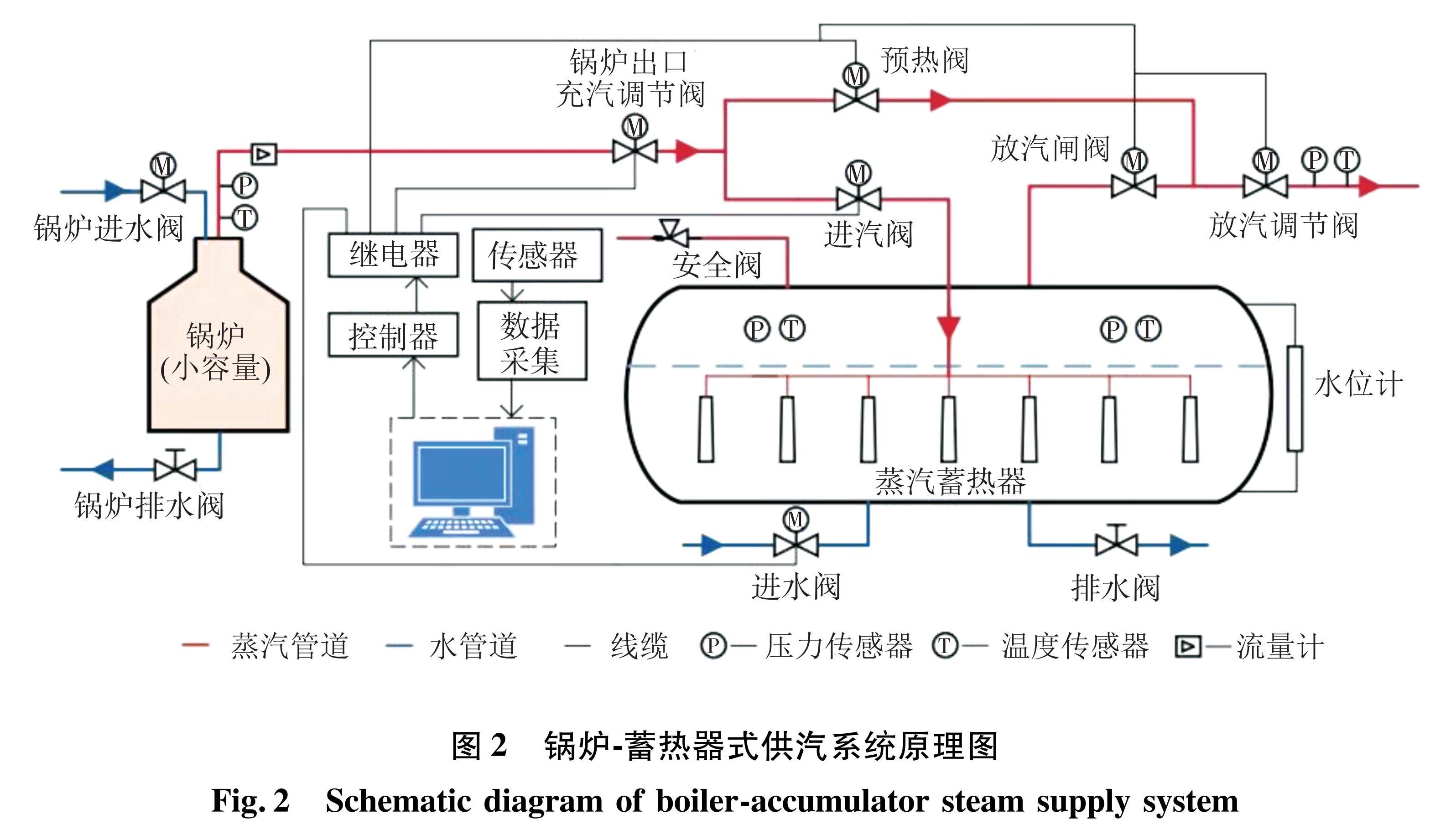

1.2 锅炉-蓄热器式供汽系统组成及工作原理锅炉-蓄热器式供汽系统原理如图2所示,该系统主要由小容量锅炉、蒸汽蓄热器、蒸汽管道、水管道、各类阀门及测控设备组成,其中锅炉产生的蒸汽通过充汽管道充至蓄热器内水空间,蓄热器打开放汽阀门通过放汽管道对下游引射器提供蒸汽,蒸汽参数可由测控系统控制相关阀门动作进行调节。

充放汽过程是锅炉-蓄热器式供汽系统的主要工作过程,其中充汽过程是通过锅炉产生的饱和蒸汽或过热蒸汽将蓄热器中的未饱和水加热至高压饱和水,放汽过程是通过打开蓄热器放汽阀门并调节其开度,使蓄热器内饱和水降压闪蒸形成满足下游要求的高温高压蒸汽。

锅炉出口设有两条蒸汽支路,其中一条通入蓄热器,另外一条为预热管道,其作用是对放汽管路和阀门进行预热。系统开始充汽前,蓄热器需注水至计算水位,并向锅炉燃油油箱加注至计算燃油量。待锅炉稳定运行后,依次打开锅炉到蓄热器之间的充汽阀门,从锅炉产生的蒸汽经由充汽管道进入蓄热器液空间。待蓄热器充至预定蒸汽压力和温度后,由于非平衡热力过程导致的蓄热器实际蒸汽压力低于理想值,以及锅炉-蓄热器供汽系统需等待下游引射器完成放汽前准备工作,故应再向蓄热器多充一部分蒸汽以抵消非平衡效应和等待过程的热损失。在下游引射器完成放汽前准备工作后,蓄热器出口放汽闸阀和调节阀依次打开进行放汽,放汽结束时先关闭放汽闸阀后关调节阀。

1.3 系统性能与结构方案设计1.3.1 热力计算与结构选型在确定引射系统用汽需求,得到用汽时间t、用汽压力pe和最大蒸汽流量Qmax这3个关键参数后,再初步确定充放汽压力,充放汽压力是锅炉-蓄热器式供汽系统的重要参数。充汽压力p1是指充汽结束时蓄热器工作压力的上限,可由锅炉额定工作压力pb(结合文献[21]初步选取)和锅炉到蓄热器的蒸汽管道压降Δp1确定,即

p1=pb-Δp1 (1)

放汽压力p2是指放汽终止时蓄热器的最低压力,通过下游用汽压力和蓄热器至引射器的蒸汽管道压降Δp2确定,即

p2=pe+Δp2 (2)

一般蒸汽管道压降要求不超过0.05 MPa[12],故此处计算充放汽压力时蒸汽管道压降取值为0.05 MPa。之后充放汽蒸汽管道设计时,应分别校核其压降不超过0.05 MPa。

从短时间消耗大量蒸汽的工作特性出发,可采用高峰负荷计算法[13]求得蓄热器理论的蓄热量G为

G=(Qmax-Q0)t (3)

式中:Q0为供汽锅炉的蒸发量; Q0较小时锅炉根据实际情况可以选择关闭,即Q0为0。

求得蓄热量后,便可计算蓄热器容积V,即

V=G/(ηφg0) (4)

式中:η为蓄热器效率; φ为蓄热器充水系数,指充汽终了时蓄热器内水体积占总容积的百分率; g0为单位饱和水蓄热量,即1 m3的饱和水完全放热所能释放的饱和蒸汽量,单位为kg/m3,表示为

式中:Hf1、Hf2分别为充、放汽压力下的饱和水的焓; Hg1、Hg2分别为充、放汽压力下的饱和蒸汽的焓; ρf1为充汽压力下饱和水的密度。

锅炉-蓄热器式供汽系统中,锅炉和蓄热器都是较为成熟的工业设备,有标准的规格系列,设计时应当首先从这些系列中选择。

锅炉的结构取决于锅炉的总体型式,可分为锅壳式(火管)锅炉和水管锅炉,在较高的蒸汽温度和压力下,水管锅炉的优势更为明显。考虑环保和经济性问题,现阶段的工业锅炉常用的是燃油或燃气锅炉,它们具有结构简单、效率高且自动化程度高等优点。在选定锅炉的结构和燃料后,结合我国工业蒸汽锅炉的标准规格系列,按照文献[21]选取锅炉的额定工作压力、额定工作温度和额定蒸发量等技术参数。

蒸汽蓄热器是外壁包覆保温层的钢制圆柱形压力容器,两端可采用半球形、椭圆形或碟形封头。其结构可分为卧式和立式两种,一般较多采用卧式结构。蓄热器筒体上开有充放汽口以装配充放汽管道,充汽管道连接锅炉和蓄热器内部蒸汽分配管道,放汽管道连接蓄热器汽空间和下游引射器。卧式蒸汽蓄热器内部充汽结构可以较好地使上下层水充分混合加热,蒸汽进入蒸汽分配管道后通过支管末端的蒸汽喷头向上喷入蓄热器水空间,在喷头上方形成部分汽水混合物,其外部配置较大直径的循环套筒。由于喷出汽流的引射作用及汽水混合物与底部水的密度差,蓄热器底部水层经循环筒向上运动进行充分换热。

锅炉、蓄热器和蒸汽管道都是受压元件,对其强度、韧性和工作性能都有较高的要求,其主要结构都由钢材构成,故要选用符合国家标准的碳钢或合金钢,比如常用的Q245R或Q345R。

1.3.2 蒸汽管道设计蒸汽管道连接锅炉、蓄热器及下游引射器构成一个完整的充放汽系统,其设计将影响到整个系统的安全稳定运行。考虑经济性和承压能力等,工业蒸汽管道常采用地上架空方式敷设,为了避免蒸汽管道和蓄热器向周围环境散发大量热量,需要在蒸汽管道和蓄热器筒体表面包覆保温层并加上蒙皮保护。一般在锅炉和蓄热器工作参数确定后便可求得蒸汽管路压降范围,再结合现场情况设计管路布局及计算管路几何尺寸。对于蒸汽管道的几何尺寸设计,通过管路布局可得到管道长度,根据锅炉的供汽流量和下游引射器的用汽流量初步确定蒸汽管道的直径为

式中:qm为管内蒸汽的质量流量; ρg为工作条件下的蒸汽密度; v为管内蒸汽的平均流速,压力在1~4 MPa的饱和蒸汽一般取20~40 m/s[22]。

蒸汽管道的流动阻力损失主要有沿程损失和局部损失,其中沿程损失为黏性流体在等截面直管中流动所产生的压力损失,假设蒸汽在管道内流速变化不大,蒸汽管道的沿程损失为

式中λp为压力损失系数,表示为

式中:l为直管段管长; Re为雷诺数。

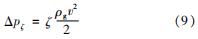

蒸汽管道的局部损失主要在蒸汽流经弯管和阀门时产生(忽略蒸汽管道进出口段的局部损失),局部损失表示为

式中ζ为局部损失系数,对于弯管,局部损失系数ζ=0.131+0.159(d/r)3.5[23],r为弯管中线的曲率半径。阀门损失系数由具体种类和结构进行计算,可参考流体阻力手册[24]。

按上述计算得到充放汽蒸汽管道上总管路流阻,以此校核充放汽压力及锅炉和蓄热器的额定工作压力。

1.4 系统测控方案设计1.4.1 功能分析及方案选择锅炉-蓄热器式供汽系统的测控部分要有数据采集与监测、自动检测和调节、自动/手动控制、故障报警及保护等功能。锅炉-蓄热器式供汽系统的工质是高温高压的水和蒸汽,并且充放汽对蒸汽参数要求也较为严格,所以测控设备对整个系统运作有着较大的影响。

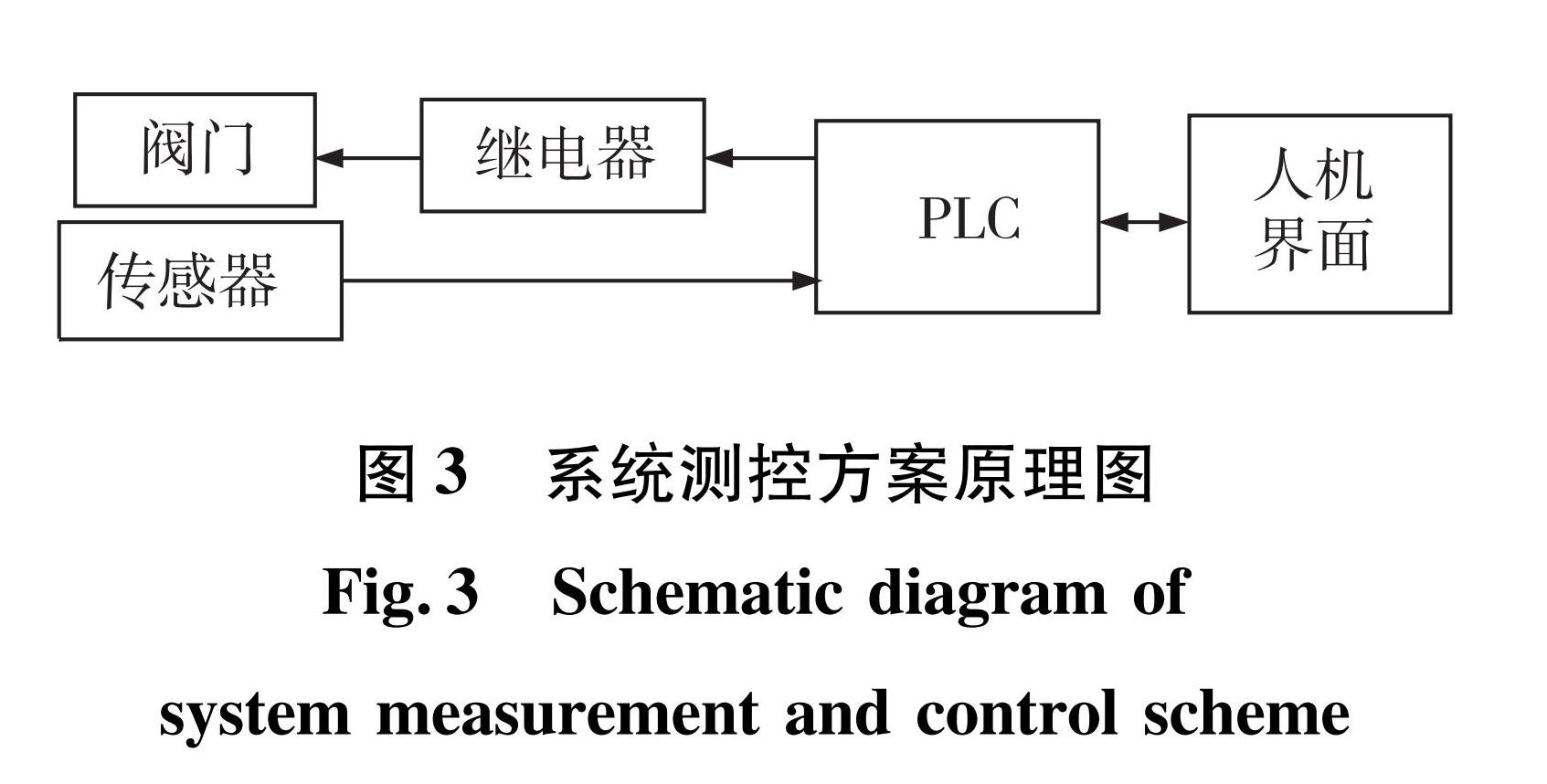

在工业自动控制领域中,可编程逻辑控制器(PLC)、单片机和工控机系统是3种常见的控制技术。PLC有可编程性、实时性、可靠性和灵活性等优点,且PLC系统通常与传感器和执行器(如马达、阀门等)配合使用,用于监测和控制工业过程。锅炉-蓄热器系统的控制主要在充放汽过程阀门控制上,故目前锅炉-蓄热器系统一般采用PLC进行控制。采用PLC的锅炉-蓄热器式供汽系统测控方案原理图见图3,系统工作时通过PLC采集传感器测量的参数并对数据进行处理和分析,再通过人机界面交互或者自动控制程序发出指令给PLC控制相应的执行器控制阀门动作。

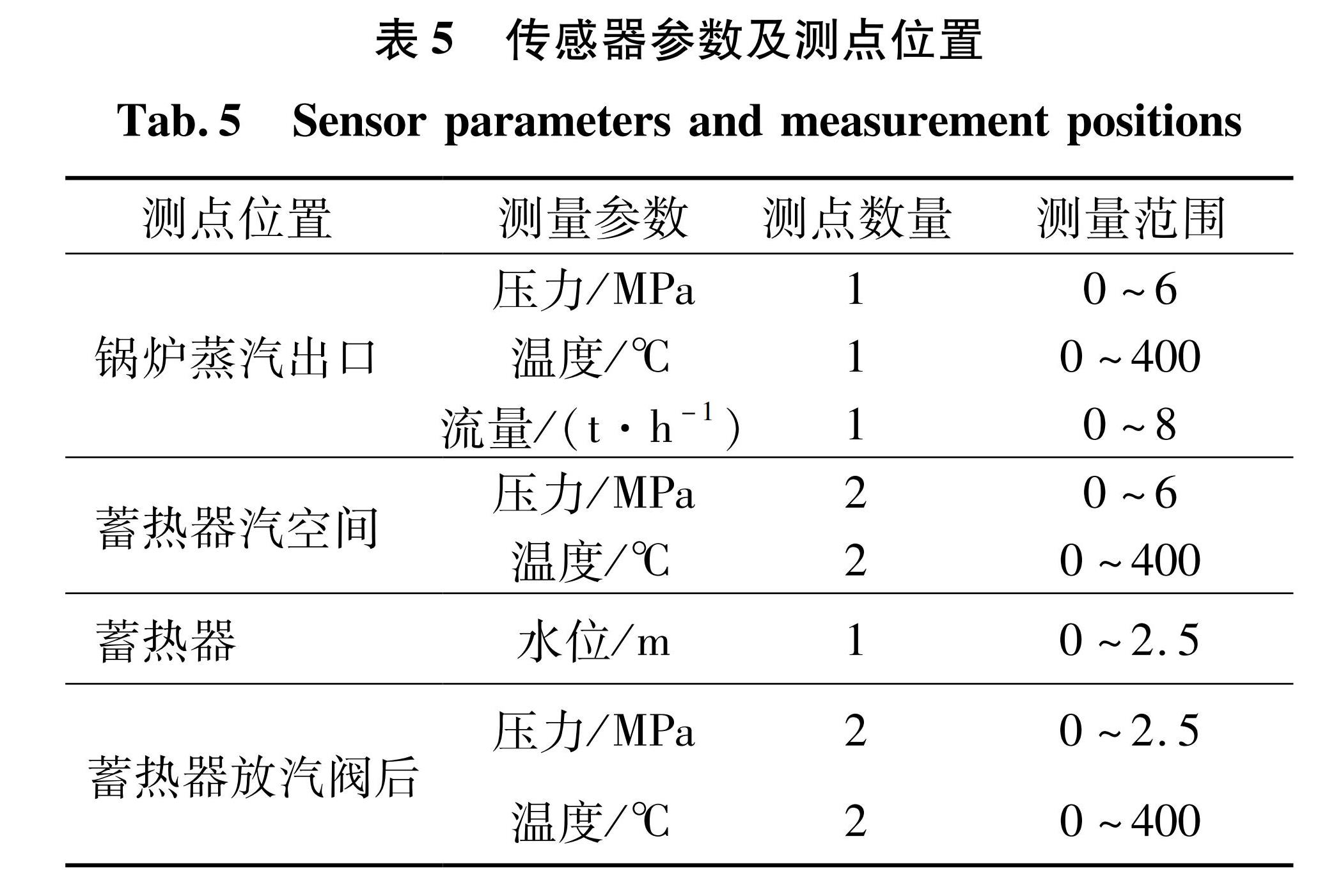

1.4.2 测点布置及阀门选型锅炉-蓄热器式供汽系统需要监测的重要参数有充放汽压力和温度、充汽流量、蓄热器压力、温度和水位等,系统的传感器布置要能覆盖这些参数,且传感器测量范围和承压能力要能满足实际工作需求。传感器测点位置如图2所示,传感器参数和数量可根据实际情况调整。

系统工作在高温高压工况下,所以蒸汽路和水路阀门要选用可以远程控制且可靠性较高的电动阀。系统充放汽过程蒸汽参数是否准确可靠,很大程度取决于系统调节阀动作是否准确,所以调节阀选型是方案设计较为重要的环节。

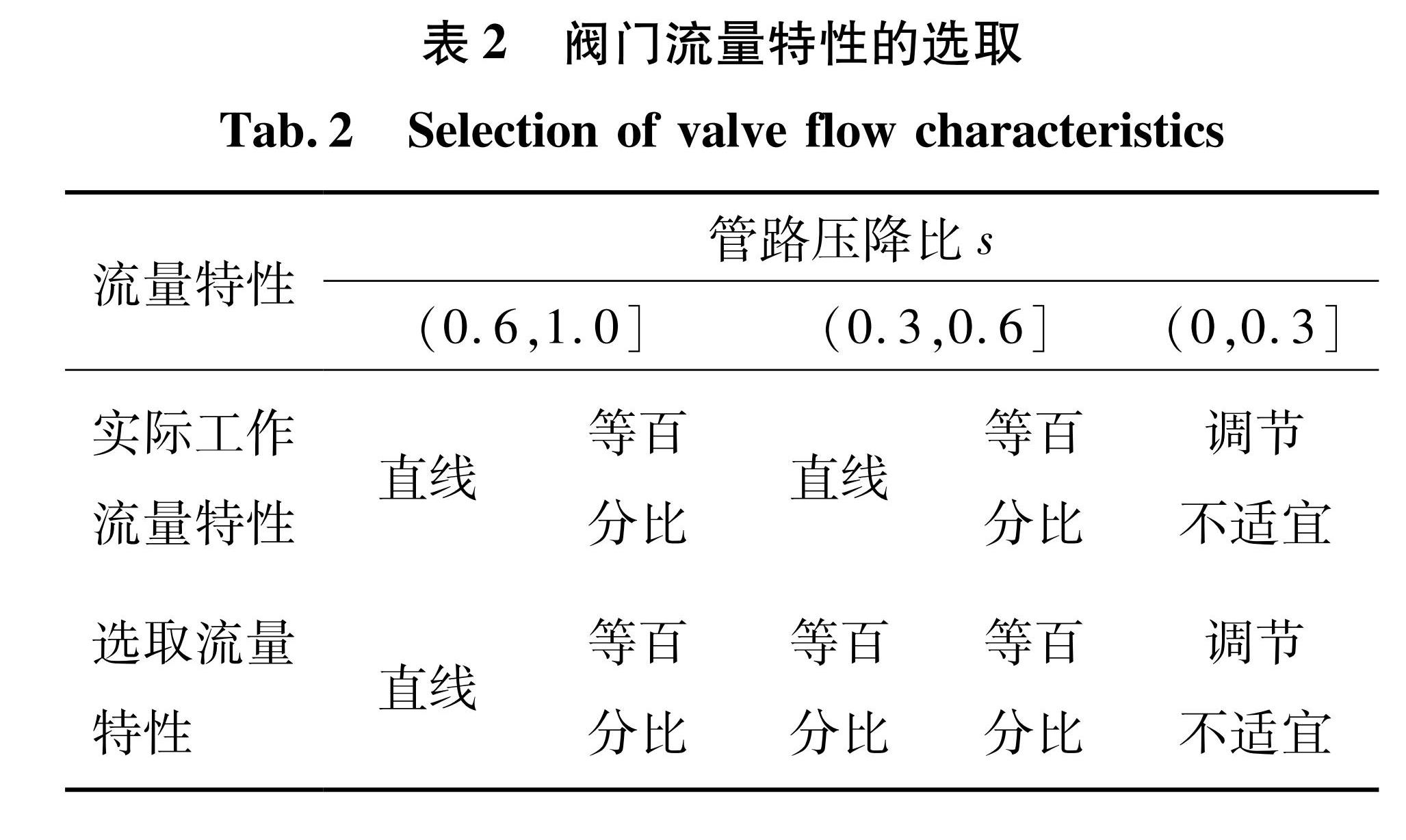

调节阀由执行机构和调节机构组成,执行机构有气动、电动和液动3类,其中电动执行机构体积小、动作可靠且便于远距离传输,故放汽路上一般选取采用电动执行的调节阀; 调节机构主要由阀盖、阀体、阀座、阀芯、阀杆、密封填料和推杆等组成,调节机构通过改变阀门开度来调节工作介质压力和流量等参数。调节阀选型时必需考虑的是流量特性和阀门口径,流量特性可参照表2通过系统的管路压降比进行选取[25],压降比s定义为调节阀的最大流量所对应进出口压差和系统压差之比,阀门口径根据系统需求的流通能力并结合厂家规格系列进行选择。

小型锅炉为大容量蓄热器充汽,充汽时间较长且对充汽流量无严格要求,故充汽阀门选取可耐高温高压的调节阀即可。蓄热器下游的引射器一般对蒸汽压力有严格的要求,且放汽时间很短,所以放汽管路上阀门的选型至关重要。

根据放汽过程特点,放汽调节阀可选用动态性能好、流量特性曲线精度高且高压差流体控制性能良好的笼式调节阀。

放汽管路上除了设置调节阀外,还需要在调节阀前设置一个闸阀,因为调节阀在高温高压下蒸汽密封效果不好,而下游引射器冷却措施未启动时蒸汽泄漏至下游可能会损坏下游设备。