作者简介:梁文栋(1994—),男,博士,工程师,研究领域为低温介质空化流动特性与机理、液体火箭发动机阀门设计与仿真。

通信作者:许健(1979—),男,硕士,研究员,研究领域为液体火箭发动机设计。

1.北京航天动力研究所,北京 100076; 2.中国航天科技集团有限公司 低温液体推进技术实验室,北京 100076

1.Beijing Aerospace Propulsion Institute, Beijing 100076, China; 2.Laboratory of Science and Technology on Cryogenic Liquid Propulsion of CASC, Beijing 100076, China

regulating valve; hydrodynamic torque; numerical simulation; influence factor; optimization design

DOI: 10.3969/j.issn.1672-9374.2024.03.006

以火星和深空探测、载人航天与探月、天宫空间站建设等为代表的我国各类航天重大工程的顺利实施,离不开我国航天动力技术60多来年的不断发展,特别是我国新一代运载火箭的首飞和工程应用[1-6]。当前,世界航天进入空间需求快速增长阶段,为了进一步提高我国进入空间的能力,降低航天运载成本,发展可重复使用液体火箭发动机技术至关重要[7-8]。可重复使用液体火箭发动机的一项重大关键技术即为大范围连续变推力控制技术[9-10]。作为变推力调节与控制的关键部件,调节阀工作环境恶劣,其可靠性直接决定液体火箭发动机的安全运行[11]。电动球阀作为近些年兴起的调节阀之一,具有开闭迅速、结构紧凑、密封可靠和维修方便等优点,可以达到较高精度和大范围的变推力控制,是美国猎鹰9号和蚱蜢系列等火箭顺利完成多次回收任务的基础。目前我国将电动球阀用于调节阀的实际发射任务较少,球型调节阀的流场分布特性、流量特性和液动力矩特性等水力性能是阀门设计研究的重点[12-13]。

实验研究是获取球阀水力性能的最好方法。2007年,Chern等[14]开展了球阀的可视化流动试验,采用粒子示踪技术拍摄了球阀流道内部的流场分布特征,分析了流型随流量和压差的演化规律。试验结果表明阀门开度越小,流道内观察到的漩涡结构越复杂。2017年,Cui等[15]采用试验和数值仿真相结合的方法研究了球阀在不同启闭时间下的瞬态性能和流动特性,指出在阀门流道内部观察到了2个显著的漩涡结构,流道下游观察到1个漩涡结构,随着开度的增加,流道下游的低压区更容易形成和发展。此外,更多的学者针对球阀的结构强度和密封性能进行了试验研究,而球型调节阀的液动力试验研究较少[16-17]。

近些年,随着CFD技术的飞速发展,越来越多的学者针对阀门内部的三维流场特性开展了数值模拟研究。2008年,沈新荣等[18]基于CFD仿真对自主设计的调节型球阀内三维流动进行了数值模拟,湍流模型选取RNG k-ε湍流模型。数值仿真提取的阀门流量系数与试验数据相一致,验证了CFD仿真技术模拟调节阀内三维流动的有效性。赵莹等[12]针对某液体火箭发动机用球阀在固定流量工况的调节特性和力矩特性开展了三维仿真分析和计算,数值结果表明该球阀的液动力矩始终表现为使阀门关闭的方向。2018年,邵洋等[19]采用数值仿真方法研究了直通式自动控制球阀的动水力矩特性,选取k-ε湍流模型模拟了水通过球阀的三维流动过程,进出口设定为压力边界条件,仿真结果表明球阀在开度和通径一定时,液动力矩与压差存在线性关系。 2020年,张增猛等[20]采用数值仿真方法对比了液压球阀在开口阀座有无倒角时的液动力分布特性,发现与无倒角情况相比,有倒角时液动力为使阀口关闭的方向,有利于稳定阀芯的运动,并且阀芯受到的液动力更大。

为了实现液体火箭发动机轻量化,降低调节阀工作电机质量,设计人员需要尽可能地减小阀芯所受液动力。目前国内学者在降低阀门液动力方面多以滑阀为主要研究对象[21],球阀研究较少。液动力补偿方法主要有阀套运动法[22]、改变流道布置法[23]、阀套斜孔法[24]及非全周开口法[25]等。王林翔等[23]对不同流道布置下的滑阀流动开展了仿真研究,指出通过改变流道布置使阀腔进出口轴向速度分量尽可能相等,可以显著减少液动力,改善阀的性能。段少帅等[24]针对滑阀提出了一种在阀套上开斜孔减小液动力的方法,并通过数值仿真对比了阀内开斜孔前后的流动特性,仿真结果验证了在阀套上开径向斜孔减小液动力的有效性。郭熛等[26]通过数值仿真对比了滑阀有无U型槽的流场分布特性,指出在相同工况下,开U型槽的阀芯比不开U形槽所受到的最大液动力要小。U型槽的宽度和深度越大,阀芯所受到的最大液动力越小。张友杰等[27]提出在阀芯上加工环形槽可以有效减小稳态液动力,减小程度与环形槽深度、宽度等因素相关,同时环形槽不能完全消除阀芯稳态液动力。李广军等[28]通过数值仿真模拟了DN500偏心半球阀在不同开度下的流场分布特性。仿真结果表明开度小于45%时,阀芯前后存在较大的速度梯度,并且在阀芯出口观察到显著的涡流。通过将阀瓣前部的弧度改为平面形状,对半球阀进行了优化设计,优化后的球阀液动力矩显著降低。

随着新研制发动机推力的不断增加,调节阀面临更高压、低温的工作环境。本文采用数值仿真方法分析某型液体火箭发动机调节阀在新型号发动机不同工况下的流场分布特性、流量特性和力矩特性,通过已有的液流试验和力矩试验验证仿真结果的准确性。获得流量和力矩随阀门开度、工况条件等参数的演化规律,基于仿真结果提出减小液动力矩的阀芯优化设计方案,对比优化前后阀芯流场,分析优化后阀芯的流场和力矩分布特性,开展试验验证液动力矩优化方案的合理性和有效性,为后续大推力液体火箭发动机球型调节阀产品的设计和改进提供参考。

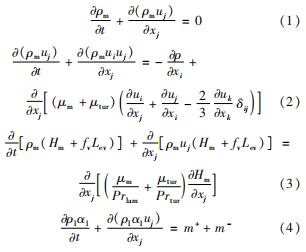

本文研究的球型调节阀在发动机运行时流过液氧介质,在液流试验中流过常温水,因此本文分别模拟了发动机运行工况下液氧和液流试验工况下常温水的三维不可压两相稳态流动。其中液氧模拟结果反映调节阀在发动机工作时的流场特性,而常温水模拟结果用来和液流试验数据对比。笛卡尔坐标系下的连续方程、动量方程、焓和质量输运方程分别为

式中:u、p、f、Lev和H分别为速度、压力、质量分数、潜热和焓; ρm为混合物密度; μm和μtur分别为混合物的层流黏性系数和湍流黏性系数; Prtur和Prlam分别为湍流普朗特数和层流普朗特数; 下标i、j、k代表笛卡尔坐标系的方向; 源项m+和m-分别表示凝结率和蒸发率。

湍流模型的选取对模拟湍流流动至关重要。本文选取标准k-ε湍流模型,该模型应用多,计算量适中,有较多数据积累和较高精度[29-31]。其收敛性和计算精度能满足一般的工程计算要求,模型参数详见文献[32]。

本文研究的某型液体火箭发动机球型调节阀计算域如图1所示,为了保证流场仿真准确性,对流场影响较大的球体密封、旋转通道和壁面等部分按照实际尺寸进行了准确建模,同时进出口分别延长10倍管道直径以确保流动充分发展。阀芯为球型,球中间位置包含直径70 mm的圆柱形流道,当球处于0°位置时,流道与进出口管道垂直,此时球对介质具有密封作用。右上角为阀芯沿着x轴逆时针旋转30°的位置,红色箭头所指区域为球外部的间隙流道,此时介质分别流过主流道和间隙流道。左下角所示为阀芯开度为90°时的全开状态,此时介质只通过主流道流动。计算域表面为无滑移壁面边界条件,进出口面的压力和流量与试验工况及实际发动机运行工况保持一致。

采用ANSYS ICEM对图1所示的三维流域进行网格划分,进出口圆柱流道采用六面体网格,几何结构比较复杂的中间阀芯区域采用四面体网格,如图2所示。本文首先计算单相定常流动过程,并将单相结果作为初值计算两相定常空化流动过程,设置RMS残差为10-4。

图3给出了开度α=30°,Δp=2 MPa时,不同网格方案下数值仿真得到的常温水液动力矩网格无关性分析结果。随着网格数量的增加,数值仿真计算得到的液动力矩先增加后减小,在网格大于130万时液动力矩随着网格的增加近似保持不变,因此本文选择130万网格方案。

发动机运行工况下阀门间隙流道为高速低压区域,仅模拟单相流动时,特定工况下在阀芯密封面边缘观察到显著的负压区域。图4给出了开度α=30°、Δp=2.5 MPa时,考虑空化模型和不考虑空化模型的仿真结果对比。如图4(a)蓝色区域所示,最小压力为-2.6 MPa,这是因为当地液相压力小于液相饱和蒸汽压,使得液相转变为气相,发生了空化现象[33-35]。为了避免负压区域影响阀芯力矩计算结果,本文选取Kubota空化模型开展定常两相流动仿真[36-37],模型参数详见文献[38]。相同工况下考虑空化模型计算结果如图4(b)所示,此时低压区域存在气相体积分数αv=0.1的空穴结构,压力最小值为常温水的饱和蒸气压3.169 kPa。无空化模型和添加空化模型液动力矩数值分别为46.6 N·m和43.5 N·m,考虑空化现象后液动力矩数值下降,因此在仿真球阀液动力矩时需要添加空化模型。对于实际发动机工况下的低温液氧仿真,由于发动机工况普遍为无空化工况,因此不需要考虑低温空化模型。

工程应用中通常采用流通面积μF来表征调节阀的流量系数,图5给出了数值仿真计算得到的阀门流通面积与文献[12]中试验数据和理论预测结果对比,试验工况见文献[12]。可以发现数值仿真结果趋势与试验数据、理论结果相一致。随着开度的增加,阀门流通面积单调增加。α>60°时,流通面积随开度变化的斜率逐渐增加。

图5 数值仿真获得流量系数与试验结果对比(常温水)

Fig.5 Comparison of the flow coefficient between the experiment and numerical simulation(room-temperature water)

本文数值计算得到的液动力矩与力矩试验结果对比如图6所示,试验数据取文献[12]中由关到开和由开到关两个过程测得液动力矩的平均值,可以发现数值结果和试验数据吻合较好。

本文结果与讨论共包含两部分内容:2.1节研究了介质为常温水时,球型调节阀在不同压差和开度下的流场分布特征和液动力矩演化规律,将总液动力矩按照分布位置不同进行了分类; 2.2节主要研究了介质为液氧时,实际发动机工况下的液动力矩和流场演化特征,同时提出了液动力矩优化方案,通过数值仿真获得了优化后模型在发动机工况下的液动力矩大小,并经过试验数据对比验证,验证了本文液动力矩优化方案的有效性,极大提高了发动机安全可靠性。

球阀在任意角度运行时,阀芯承受流体分布压强,其合力称为液动力,液动力分为稳态液动力和瞬态液动力,与稳态液动力相比,瞬态液动力一般可以忽略不计[22]。稳态液动力对阀芯操纵有很大影响,特别是在高压大流量的液体火箭发动机中,需要避免液动力大于控制力,使阀芯动作失效的情况。准确预测球阀液动力矩,通过优化设计结构降低电机维持球阀开度所需的力矩,对提高发动机可靠性、实现发动机轻量化具有十分重要的意义。目前在球阀设计中,稳态液动力矩的取值来源于文献[39]提出的经验公式,即

M=md3Δp(5)

式中:M为液动力矩; m为开度系数; d为流道直径; Δp为压差。式(5)表明球阀阀芯所受液动力矩与开度、流道直径和压差有关。

本文首先对比了数值仿真和依据经验公式[式(5)]获得的3种压差下(0.5、1.5、2.5 MPa)阀门液动力矩随开度的演化特性。如图7(a)所示,离散点代表经验公式预测的力矩结果,实线代表数值仿真数据,二者预测力矩变化趋势相一致,在相同压差下,阀门液动力矩随开度的增加逐渐增加。经验公式无法判断力矩方向,而数值仿真所得力矩方向均为使阀芯关闭。在同一压差下,开度大于40°时,数值仿真和经验公式结果存在显著的差异。当压差0.5 MPa增加到2.5 MPa时,数值仿真结果和经验公式预测结果差异显著增加。如图7(a)所示,开度为50°时,3种压差(0.5、1.5、2.5 MPa)下数值仿真得到的力矩和经验公式预测结果差值分别为8.6 N·m、21.5 N·m、46.1 N·m,维持调节阀正常工作的电机额定力矩为50 N·m。这表明基于经验公式的液动力矩预测在压差大于1.5 MPa时具有显著的误差。图7(b)给出了不同压差下力矩比值分布,纵坐标为力矩比值。由图7(b)可知:相同开度下,压差从0.5 MPa分别增加到1.5 MPa和2.5 MPa, 液动力矩增加也分别近似为3倍和5倍,所以液动力矩和压差近似呈线性关系,与经验公式预测趋势相一致。随着新型发动机推力和系统工况压差的进一步增加,在未来新型号研制工作中,基于经验公式的力矩预测结果不再具有参考价值,必须开展相应的CFD数值仿真工作获得液动力矩,为调节阀电机的选取提供准确的力矩数值。

(a)数值仿真力矩和经验公式力矩对比

(b)不同压差力矩比值分布

图7 不同压差下数值仿真所得力矩随开度变化与经验公式结果对比(常温水)

Fig.7 Comparison of the hydrodynamic torque between the equation and numerical simulation at different openings(room-temperature water)

图8给出了Δp=1.5 MPa时3种典型开度下的压力和速度分布云图,流动方向为从上到下。3种开度下介质均会流经两侧的间隙流道和中间的主旋转通道,随着开度的增加,间隙流道横截面积单调变小,主旋转通道横截面积单调增加。阀芯开度α=30°时,主旋转通道下壁面形成一个漩涡区域,同时在主旋转通道其他区域观察到一个显著的漩涡结构。随着开度的增加,主旋转通道下壁面的漩涡结构逐渐向上移动,在α=70°时,漩涡出现在靠近阀腔上壁面处。而主旋转通道剩余区域的显著漩涡结构在α=50°和α=70°时均未观察到。α=30°时间隙流道区域的速度大于主流道,平均速度为47 m/s,阀门流通能力取决于间隙流道大小。而α=70°时,主旋转通道区域的平均速度为65 m/s。

图8 不同开度的压力和速度云图分布(常温水,Δp=1.5 MPa)

Fig.8 Distribution of the pressure and velocity at different openings(room-temperature water, Δp=1.5 MPa)

液动力矩是电动调节球阀设计的一个重要参数,是电机设计最重要的依据。数值仿真的液动力矩通过CFD Post软件可以直接提取,提取液动力矩需要确定旋转轴和二维平面。旋转轴为图1所示的x轴。为了分析阀芯液动力矩的分布特性,本文将阀芯分为3种类型的二维平面,如图9所示,分别为主流道面、密封面和其他球面。

图 10给出了发动机在27%~100%运行工况下调节球阀3种平面受到的液动力矩随开度演化规律,力矩数值为正代表阀芯关闭,力矩数值为负代表阀芯打开。在所有开度下,球面受到的液动力矩数值近似为0,这表明球阀液动力矩由主流道力矩和密封面力矩组成。如图 10所示,随着开度增加,主流道力矩先增加后减小,最大值为155.7 N·m,出现在α=63°左右。 而密封面力矩最大值为43.8 N·m,出现在α=36°时。随着开度增加,密封面力矩先减小后增加。α>53°时,密封面所受力矩数值变为负值,方向由使阀芯关闭变为使阀芯打开。

为了分析3种平面液动力矩的演化规律,图 10(b)和图 10(c)分别给出了27%工况和100%工况下的阀芯压力云图,阀芯打开方向为逆时针。27%工况时α=36°,此时开度较小,3种平面压力分布区域如图中虚线区域所示。密封面液动力矩主要来源于上密封面的粉色虚线区域,该区域面积随着开度的增加逐渐减少,因此密封面液动力矩逐渐减小,在100%工况时,上密封面不会受到介质的压力,此时密封面液动力矩数值为0 N·m。蓝色区域为主流道压力分布显著的区域,在100%工况α=72°时,该区域可以观察到显著的高压分布特征。

在额定100%工况运行时总液动力矩为132.8 N·m,远大于电机的额定工况50 N·m,这就需要增加电机力矩,但会使电机结构质量增加,不符合轻质化设计要求。因此,亟需针对该型球阀开展液动力矩优化设计工作,在不增加电机力矩的前提下保障电动球阀的正常运行。

在阀门设计过程中,为了降低阀芯液动力矩,设计人员依据经验公式(5)往往采用减小主流道直径的方案。图 11(a)给出了不同开度下,主流道直径分别为60 mm和70 mm时的阀门流通面积。相同开度时,降低主流道直径,会使得阀门流通面积下降,开度越大,流通面积下降越多。相同发动机系统工况下,与70 mm的阀芯相比,60 mm的阀芯需要增加开度以满足系统流通面积要求。

阀芯球径d=60 mm时,发动机在27%~100%运行工况下的3种平面液动力矩随开度变化如图 11(b)所示。每个工况下的开度与球径d=70 mm的开度[如图 10(a)所示]相比均有所增加,其中27%工况和100%工况下开度分别增加了8.5°和6.0°。d=60 mm时3种平面液动力矩随开度变化趋势与d=70 mm保持一致。其中球面液动力矩近似为0。与球径d=70 mm时液动力矩[如图 10(a)所示]相比,d=60 mm时100%工况下阀芯总液动力矩增加了4.3 N·m。其中密封面最大力矩降低了10.4 N·m,主流道最大力矩增加了20.1 N·m,总液动力矩最大值增加了24.5 N·m。这是由于相同工况下d=60 mm的阀芯开度变大导致的。增加开度使得密封面压力分布区域减小,密封面液动力矩减小,而主流道压力分布区域增加,总液动力矩增加。因此,采用降低阀芯流道直径的方案时,相同发动机工况下阀芯开度增加,使得阀芯总液动力矩增加,不满足降低力矩要求。

图 11 3种平面液动力矩随开度变化(液氧, d=60 mm)

Fig.11 Variation of the hydrodynamic torque with openings in terms of three planes(liquid oxygen, d=60 mm)

由CFD数值仿真提取的3种平面力矩结果可知,为了减小总液动力矩,需要对密封面和主流道面进行优化设计。为了保证阀门全闭状态的密封效果,密封面优化设计受到很大限制,本文主要针对主流道进行优化设计研究。图 10分析结果表明主流道液动力矩来源于入口下壁面位置,削掉下壁面可以使介质不会对阀芯产生显著的压力分布。图 12(a)给出了本文的优化方案示意图,在距离球心l1处削去右侧的全部球体,优化后的阀芯模型如图 12(b)所示。

图 12 减小液动力矩的阀芯设计优化方案(d=70 mm)

Fig.12 Optimization scheme of the ball valve design for reducing hydrodynamic torque(d=70 mm)

图 13(a)和图 13(b)分别给出了优化前后模型的流通面积和液动力矩对比示意图。如图 13(a)所示,相同开度时,优化模型的流通面积与原始模型基本一致,这表明相同发动机工况时,优化模型具有与原始模型相同的阀芯开度。如图 13(b)所示,与原始模型相比,优化后模型液动力矩显著下降,力矩最大值为52 N·m,减小了94.4 N·m。其中100%工况下优化模型液动力矩为-13.2 N·m,方向为使阀芯打开。现有电机最大操纵力矩为80 N·m,具备维持球阀正常运行的能力。优化模型力矩随着阀芯开度增加而降低,数值大小和演化趋势与原始模型的密封面力矩基本一致。这是因为优化模型削掉了主流道下壁面,使得主流道力矩降低为0。此时优化模型的总液动力矩即为密封面力矩。

图 13 优化前后阀芯模型流通面积和力矩对比(液氧,d=70 mm)

Fig.13 Comparison of the flow coefficient and hydrodynamic torque between the original model and optimized model(liquid oxygen, d=70 mm)

典型工况下优化模型的压力云图和流线分布如图 14所示。60%工况时在主流道中心区域和阀芯出口分别观察到了显著的漩涡结构。随着开度的增加,主流道漩涡结构消失。100%工况时在阀芯右侧观察到漩涡结构。与原始模型相比,优化模型的压力分布区域由主流道下壁面区域转移到壳体右下角壁面区域,此时阀芯液动力矩主要来源于图中黑色虚线所示的密封面区域,低工况的力矩大于高工况。

本文通过数值仿真研究了某型调节阀在发动机运行工况时的流场特性,空化模型和湍流模型分别采取kubota空化模型和标准k-ε湍流模型。数值计算获得的流通面积和液动力矩与液流实验数据基本吻合,验证了数值模型的准确性。讨论了阀芯液动力矩的影响因素、分布特性和演化规律,基于仿真结果提出了减小液动力矩的阀芯优化模型,该模型已经通过多轮发动机试车考核,得到如下主要结论。

1)液动力矩大小与阀芯开度、压差和流道直径有关。相同压差下,开度由10°增加至80°,液动力矩单调增加,方向均为使阀芯关闭。相同开度下,压差分别增加3倍和5倍,液动力矩分别变化为原来的3倍和5倍左右。α=30°时,阀芯流道区域观察到数个显著的漩涡结构,随着开度的增加,主流道漩涡结构消失。

2)液动力矩分布主要由密封面力矩和主流道力矩两部分组成。随着开度的增加,密封面力矩先减小后增加,主流道力矩先增加后减小。阀芯流道直径由70 mm减小为60 mm,液动力矩最大值增加了24.5 N·m。这是因为相同发动机工况下,减小流道直径使得阀芯开度增加,主流道力矩增加数值大于密封面力矩减小数值,所以总液动力矩呈增加特征。

3)本文依据阀芯压力分布情况,提出了削去主流道下壁面区域的液动力矩优化方案,显著降低了阀芯液动力矩,减轻了球阀控制电机的力矩负荷。优化后模型成功通过了多次发动机热试车考核,为今后大推力液体火箭发动机球型调节阀的设计和改进提供了参考。