基金项目:国家自然科学基金青年项目(51906194); 国家自然科学基金面上项目(51876153)

作者简介:孙靖阳(1998—),男,博士,研究领域为液体火箭低温推进剂热管理。

通信作者:毛红威(1993—),男,助理教授,博士,研究领域为液体火箭低温推进剂两相流动传热。

1.西安交通大学 航空动力系统与等离子体技术全国重点实验室,陕西 西安 710149; 2.西安交通大学 未来技术学院,陕西 西安 710149,西安; 3.西安交通大学 机械工程学院,陕西 西安 710149; 4.西安交通大学 能源与动力工程学院,陕西 西安 710149

1.National Key Laboratory of Aerospace Power System and Plasma Technology, Xi'an Jiaotong University,Xi'an 710049, China; 2. School of Future Technology, Xi'an Jiaotong University, Xi'an 710149, China; 3. School of Mechanical Engineering, Xi'an Jiaotong University, Xi'an 710149, China; 4. School of Energy and Power Engineering, Xi'an Jiaotong University, Xi'an 710149, China

gas emulsification; gas generator; liquid-gas flow; fitted laws of pressure drop

DOI: 10.3969/j.issn.1672-9374.2024.03.012

液氧煤油高压补燃循环发动机已经成为我国新一代运载火箭CZ-5、CZ-6及CZ-7的主动力[1]。补燃循环具有二次燃烧,是一种闭式循环,可使化学能释放更为充分。但是,补燃循环液体火箭发动机系统更加复杂,参数间耦合性强,技术难度高[2]。尤其是在变推力调节过程中及发动机启动初期,燃料头腔中的压力显著低于额定工况,导致经过喷注器的压降较小,直接影响燃料的雾化和燃烧效果,此时需要提高压力,增强喷注器的雾化效果。Bradley[3]通过量纲分析的方法指出黏度对破碎过程的影响可忽略,而雾化压力和表面张力是该过程的重要物性参数。司朝润等[4]通过实验明确证实当雾化压力较大时液膜破碎产生的液滴粒径更小。朱玲玲等[5]通过CFD方法,发现雾化压力与质量流量之间存在正相关性,即当压力增大后,气体流速更大,能够交换的能量更多,从而使得液体的总表面能更大,形成更多细小液滴。徐文等[6]通过数值模拟的方法,基于VOF-to-DPM模型对离心式喷嘴的破碎及雾化过程进行了分析,发现当入口流量较低时,由于流速较低,柱状流难以拓展为液膜,在雾化锥的表面存在较多纵向大液块,而在流速较高时,空心液锥表面较为稳定,且截面更接近圆形,雾化效果更好,证明离心式喷嘴在高流速、高压降工况下具有更好的雾化性能。文献[7-8]通过ALE(Arbitrary-Lagrangian-Eulerian)方法来捕捉气液相界面,对离心式喷嘴的流体域进行了数值分析,分析了离心式喷嘴内的流动特性与填充特性。文献[7]明确了黏度是影响雾化效果的重要参数,无黏假设会导致计算液膜厚度小于实际厚度,而雾化锥角则大于实际角度。周立新等[9]在离心式喷嘴数值模拟方面进行了大量工作,通过给定切向速度的方法,对离心式喷嘴内部流态进行分析,结果表明:切向速度使液膜旋转卷吸环境空气,在喷嘴内部形成一个气锥,气锥的形态将在极大程度上影响雾化效果,并明确了气锥形态与压降之间存在明显的函数关系,在离心力的作用下,喷嘴壁面处液膜表面的压力沿径向逐渐升高,而当液体靠近出口时,背压将对液膜的压力场产生影响,导致压力下降,液膜内的压力能将转变为动能,使前后流体产生速度差,从而撕裂液膜,完成雾化。实验方面,张涛等[10]针对气液同轴双离心式喷嘴中的雾化特性展开了实验研究,其研究结果表明:增大气体流量可使喷嘴出口的雾化锥由空心逐渐转为实心,使雾化效果提高,并明确了液体雾化存在表面波破碎、波动破碎及气动破碎3种方式,随着气体流量增大,液体雾化方式逐渐由表面波破碎过渡至波动破碎,此时雾化锥将逐渐收缩并逐渐趋于稳定。

另外,大量实验结果表明,燃气发生器的喷嘴压降通常需要达到头腔压力的15%~ 20%才能够使燃料充分雾化并均匀、稳定地燃烧,而部分特殊的喷注器可以将该压降范围扩大到5%~25%[11-12]。

不同推力对应了不同的燃料流量,为了满足喷注器的雾化压降需求,各个国家在研制变推力火箭时都做了许多研究。其中,利用气体提高喷注器内单相液体压降的气体吹除乳化技术是变推力发动机研制过程中不可缺少的方案,SE-10、RL10A-1等多种火箭发动机均采取了使用气体吹除方案的喷注器[13]。图1展示了气体吹除乳化的过程:高速流动的气体和液体在混合腔内进行强烈的动量交换,从而导致气相的相界面破碎,生成致密且均匀的小气泡弥散在液相中。由于混合头腔中气体压缩的过程很快,该过程可视为绝热过程。

美国国家航空咨询委员会的路易斯研究所在1956年论证了利用氦气吹除方案使得燃料液体呈现泡沫状,从而在不影响燃烧效率的条件下实现变推力调节的可行性[14]。因为压降与液体燃料的体积密度呈现明显的反比关系[15-16],故文献[13]认为气体吹除方案的本质是降低了液体燃料的体积密度,在小燃料流量的工况下仍然能够保持较大的体积流量,从而满足喷注器的压降要求。Bendix公司的研究结果表明气体吹除乳化技术拥有很高的节流比,故该技术仅需少量气体就能够达到变推力工况所需的压降要求。在使用氮气作为吹除气体时,节流比可以达到35:1,而使用氦气时则可能达到50:1[17],相较于节流比约为27:1的常规针栓式喷注器[18]或是节流比约为10:1[19]的旋流式喷注器具有明显优势。另外,气体的吹入还能够有效防止湿气在发动机内壁凝结和煤油结焦等问题的发生,从而保证发动机运行过程的安全稳定[20]。因此,气体吹除乳化技术是在不影响燃烧效率的情况下实现液体火箭发动机大工况范围和大流量变推力技术的重要手段。但目前国内对气体吹除后喷注器内压降变化规律的定量研究还有所欠缺。因此,有必要针对气体-燃料两相流在喷注器内的压降变化规律展开深入研究。

为系统性探究气体吹除乳化过程中压降与流量等参数之间的定量关系,本文以某型号燃料头腔喷注器结构为研究对象,建立喷嘴模型,进行仿真计算分析,通过对单相流及气液两相流压降规律开展数值研究,建立压降与气液流量及燃气发生器内部压力的函数模型。本文工作能够为发动机气体吹除乳化技术的压降预测及工况优化提供理论参考与数据支持。

某型号液氧煤油发动机燃料头腔及喷注器的流体域中心剖面结构如图 2所示,关键参数已于图中标出。煤油与氮气分别沿混合腔的径向和轴向注入燃料头腔进行混合并逐渐形成乳化体,分流至各喷嘴后完成雾化,再进入燃气发生腔内实现充分燃烧。气液混合腔内布置有一个阀芯结构,用于在变工况下调节液体燃料流量。

目标喷注器的结构共有7个喷嘴,不同喷嘴之间的结构具有相似性。图 2给出了中心喷嘴的流体域结构,喷嘴流体域包括外壁环、节流管以及出口段3部分。

本文包含了对燃气发生器全域流场及中心单喷嘴共两种不同结构的仿真计算,二者共用一套数值仿真模型。

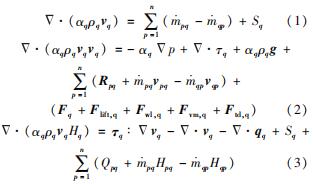

在气体吹除乳化过程中,燃气发生器全域流场内物理场充分发展所需时间占总燃烧时间极短,故压降采用稳态方法计算。其控制方程不包括时间项,且液相和气相中各包含一种物质,不考虑组分输运,Eulerian模型中气液两相流的质量方程、动量方程和能量方程可简化为

式中:α为控制体内体积分数; 角标q指代控制体中任意一相,角标p指代控制体中除q外的任意一相; m·pq和m·qp表示相间质量传递过程; Sq为质量源项; τq为切应力张量; g为重力加速度; R为相间作用力,与滑移速度相关; Fq、Flift、Fwl、Fvm、Ftd分别为外部体积力、升力、壁面润滑力、虚质量力及湍流耗散力; H为比焓值; qq为相q与外环境之间的热流密度; Sq为热量源项; Qpq为相之间的换热量; Hpq为相间焓。

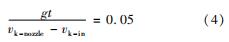

燃气发生器结构内高速流动的气液两相界面状态复杂,且存在明显的相间滑移,本文采用Eulerian多相流模型描述气液高度混合的物理场[21],同时通过universal-drag曳力模型描述大气量、多气泡型的气液动量交换,在气体吹除乳化过程中对应温度区间(272~288 K)内,煤油主要成分正癸烷的对应表面张力范围为24.535~25.877 mN/m,相对变化不超过5.5%,故按照定值计算。考虑到煤油流速很大,惯性力远大于体积力,煤油从进入到流出燃气发生器所用时间约为0.35 s,在该时间内,重力冲量与喷嘴处煤油动量变化的比值为

式(4)表明重力对煤油流动影响很小,故忽略重力。湍流模型选择应用广泛、在预测圆柱射流传播方面以及热交换方面具有计算优势的realizable k-ε模型[22-23]。该模型十分适合节流管内的高速流动,对曲型流线和回流现象有很好的预测效果,且可以精确描述节流效应产生热交换带来的影响。同时,激活湍流模型的曲率修正以更准确地描述弯曲流线。从几何角度看,从入口到出口的流道具有多个弯折和曲线过渡,这要求物理模型具有高计算精确度。

由于喷嘴的入口和出口存在很大压差,整个流体域内的气体密度将发生极大的变化,故氮气的密度基于r-k真实气体方程进行计算。包括煤油密度在内的其他物性参数在边界条件范围内变化不大,均设为定值。

为了提高计算的精度以及鲁棒性,采用Coupled算法将压力与速度的离散格式进行耦合,体积分数离散格式采用modified HRIC格式,压力离散格式采用能够更好地描述大密度差的体积力加权算法,湍流离散格式采用一阶迎风格式,其余均为二阶迎风格式。当各残差均小于10-3(能量残差小于10-6)且进出口流量差小于5%时判定仿真收敛。

喷嘴部分采用ICEM绘制结构化网格,进出口平均压降随着网格尺度的变化如图3所示。当网格尺寸小于0.6 mm时,压降的波动幅度将小于1%,达到网格无关性要求。最终确定网格尺度为0.4 mm,采用渐扩式边界层,网格数量为13.5万。整体计算模型则按照网格尺寸为0.4 mm通过FLUENT meshing进行非结构网格划分处理,总网格数68万。

将数值仿真结果与西安航天动力研究所某典型实验数据进行比对可知,在气体流量0.140 kg/s、液体流量1 kg/s、背压0.37 MPa时,实验测得燃气发生器头腔内压力为1.72 MPa,本文数值仿真计算结果为1.70 MPa,相对误差1.16%,验证了模型的准确性。

以该型号发动机某一典型工况为例开展全流场两相流计算。煤油流量为0.48 kg/s,氮气流量为0.021 kg/s,喷嘴出口背压为1 MPa,气液相初始温度均为288 K。

燃气发生器仿真压力分布如图 4所示。混合腔总体压力维持在3.4 MPa以上,最高压力达到3.6 MPa,最低压力为0.6 MPa,出现在节流管入口处。全域流场压降集中在节流管内,达到了2.5 MPa。

图5展示了单个喷头的煤油局部速度矢量图,在节流管道中,煤油速度达到75 m/s以上,远超过其他部位。煤油和氮气在混合头腔均匀混合后,经由分流管道进入喷嘴中,撞击到喷嘴内壁面后向四周逐渐填充,并形成多个流动涡和环形流线。喷嘴的出口段与外环流域之间通过节流横管相连接,这根横管的通流面积很小,是流动阻力的主要来源,根据伯努利方程,此处有大量压力能转化为动能,流速急剧升高。两相流以流速撞击至出口段侧壁面后,将会向两侧分散,形成两个漩涡,撞击点的静压值有所回升,漩涡内部将会卷吸回少量气体。

燃气发生器头腔全结构全流量的煤油相分布如图 6所示。从仿真结果来看,煤油相分布并不均匀。从截面图可以看出,由于阀芯阻挡了氮气的流动,煤油无法充分与氮气进行动量交换,而煤油本身仅有水平方向的流动速度,这导致煤油直接冲击到阀芯底层,在此处依靠撞击获得部分竖直方向的速度分量,最终表现为煤油的贴壁现象,且在沿管道流动过程中,煤油和氮气逐渐混合。

以分流管入口为基准截面y=0,逆流动方向为正向,则混合腔内煤油相分布如图 7所示。从图中可看出,煤油和氮气在流动过程中逐渐混合,煤油有向中心聚拢的趋势。而在进入分流管道前,大量的煤油沿着混合腔管道段底层流动至出口,有27.4%的通流面积均被体积分数超过80%的煤油占据,这表明煤油流量分布不均且进入分流管路无法按照额定配比分配流量,煤油出流量最高的喷嘴是出流量最低喷嘴的1.66倍,外环6个喷嘴的流量如图 8所示。

静态喷注器的喷嘴对应的额定压降不可调节,且仅当燃料经过喷注器时产生的压降与额定压降相近时才能被充分雾化。在燃气发生器中,增加气体吹除乳化过程的目的是为了增大液体的体积流量,从而保证在变工况条件下低流量的液体燃料在经过喷嘴时所产生的压降能够满足充分雾化的需求,即喷嘴压降是气体吹除乳化过程的核心参数。

考虑本燃气发生器各喷嘴结构的相似性,选取中心喷嘴开展压降特性研究。同时考虑气体流量、液体流量及背压变化的影响,流量工况范围在标准工况的25%~ 100%之间变动(见表 1)。在燃气发生器工作且采用吹除乳化技术时,常用工作压力在8 MPa附近,故本文选取具有代表性的4 MPa以及常用工作压力8 MPa作为计算对象,并以6 MPa背压时的计算结果作为验证对象。在表 1中,各工况之间进行交叉计算,即每个气体流量均对应5个液体流量和2个背压,共计5×5×2=50组工况。为方便后续阅读,文中用角标n代表氮气气相,用角标k代表煤油液相。

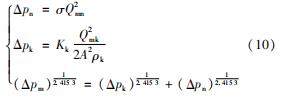

喷嘴结构的绝对尺寸很小,产生的沿程阻力可以忽略,压降主要由局部阻力产生。单相流压降可以基于流体力学局部阻力损失的经典表达式进行分析,即

式中:hm为局部阻力损失(无量纲); K为局部阻力系数; v为节流管内局部流速; g为重力加速度,取9.8 m/s2。

中心喷嘴内氮气单相流压降规律如图9所示,可以发现,喷嘴压降和氮气质量流量Qmn的平方之间呈现明显的线性关系,且在不同背压下具有不同的斜率。针对本结构,可定义压降特性系数为

式中:Kn为氮气对应的阻力系数; A为节流管的横截面积; ρn为氮气密度。

基于图9中多组流量工况的压降数据,对σ进行拟合,得到

σ=6.124-0.506 3pb (7)

式中pb为背压。

针对图9中工况,将式(7)代入式(5)计算得到的压降值与数值计算结果的平均相对误差为0.41%。进一步针对氮气流量为3.3 g/s、背压为6 MPa的工况开展验证计算,由式(7)预测的压降值相对于数值计算结果的误差为8.7%。证明在不同流量与背压工况下式(7)对本结构的氮气单向流压降具有良好的预测精度,且通过该种方式定义的流量特性参数在数值上具有明显线性关系,当结构固定时,更利于实际工程使用。

煤油的单相液体压降及阻力系数Kk的变化规律如图 10所示。从图中可以看出,不同背压下的压降变化曲线几乎重合,这主要是由于煤油为不可压缩流体,背压的变化不会对煤油的密度及流速产生明显影响,进而不会明显影响其流动损失特性。可以看出,Kk与煤油质量流量Qmk具有明显的幂函数变化关系,通过数据拟合,可以得到

Kk=2.019×Q0.066 53mk (8)

图 10中展示了基于式(8)得到的预测结果,该结果与数值计算数据吻合良好,最大相对误差为1.32%。

为了进一步描述压降随流量的变化规律,本文采用在发动机两相流动领域中得到广泛应用的马尔基涅利公式预测不同流量所对应的结构压降,即

(Δpm)1/n=(Δpk)1/n+(Δpn)1/n (9)

式中:Δpm、Δpk、Δpn分别为两相流压降、氮气压降及煤油单相流压降; n为与结构有关的无量纲经验系数。

将第3节中数值计算得到的单向流与多相流压降数据代入式(9),各工况对应的n值如图 13所示。在不同背压下,各组流量工况的平均n值均为2.415 3,且n值随气、液流量的变化幅度很小,可以认为n值主要与结构有关,而基本不受背压、流量等参数的影响。

以仿真计算的多相流压降结果(图 11和图 12)作为基准,将气、液单相流数值仿真计算结果(图 9和图 10)与平均n值(2.415 3)代入式(7),计算得到压降数据,该值相对于仿真压降数据的平均误差为3.94%,最大误差为9.55%,呈现了良好的预测精度。

对任意固定结构,假设对应n值已知,采用马尔基涅利公式进行两相流压降预测时,还需要首先获得每组工况对应的单相流压降数据,以便于实际应用的快速预测。前文已经计算分析了不同背压、不同流量和不同气液流量比下的单相流及两相流的压降规律特性,并获得了气相和液相单相流情况下阻力系数Kk的拟合关系式为了使模型的使用更加简便,本文在传统马尔基涅利公式基础上,直接将3.1节中拟合得到的单相流压降公式代入式(7),通过式(7)对本结构的压降特性进行计算,可得

基于式(10),可以直接根据气、液流量及背压等工况参数计算得到相应的压降值。图 14给出了表 1所列工况的预测值与仿真计算数据之间的对比情况。式(10)相对于仿真压降数据的最大误差为10.68%,平均误差为3.91%,表明结合单相流压降拟合公式与马尔基涅利公式的预测方法对多相流压降具有较好的预测性。

本文针对燃气发生器头腔吹除乳化过程及关键部件喷嘴的压降特性进行了仿真计算研究,得到了相关结构的压力、速度、相分布云图,并通过数据处理分析,总结出以下结论。

1)气体吹除乳化过程可以显著提升煤油经过燃气发生器内产生的压降,从而满足喷嘴处压降需求,使煤油能够充分雾化。

2)在气体吹除乳化过程中,燃气发生器内的压降集中在喷嘴节流管处,在标准工况(煤油流量为0.48 kg/s,氮气流量为0.021 kg/s)下达到2.5 MPa,其他区域无明显压降。同时,燃气发生器内的煤油分布不均,存在煤油贴壁流动的现象,靠近煤油贴壁侧的喷嘴流量更高。

3)基于流体力学经典局部阻力公式对喷嘴单相流压降进行分析,发现煤油单相流对应阻力系数Kk与煤油质量流量呈幂函数变化规律,氮气单相流对应压降特性系数σ与背压之间呈现线性变化规律。

4)基于马尔基捏利式(9),本文喷嘴结构的系数n可看作定值2.415 3,结合单相流压降拟合式(7)和式(8)后,本文所提出的喷嘴两相流压降简化模型(10)与仿真计算的最大误差为10.68%,平均误差为3.91%。本文采用的基于仿真计算结果构建两相流压降预测模型的方法可以沿用至其他型号结构的气体吹除乳化过程。