作者简介:赵灿(1989—),男,硕士,高级工程师,研究领域为液体火箭发动机无损检测技术。

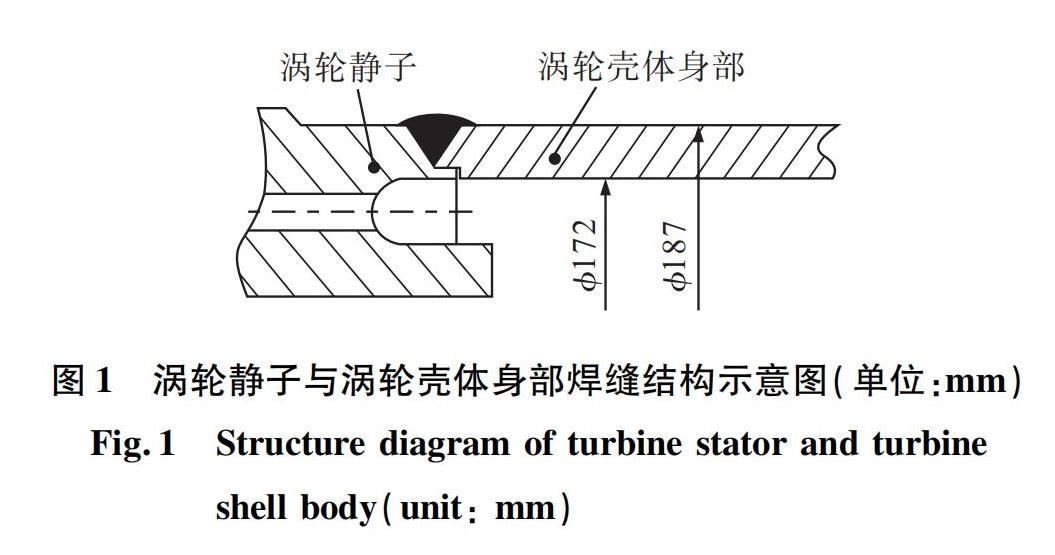

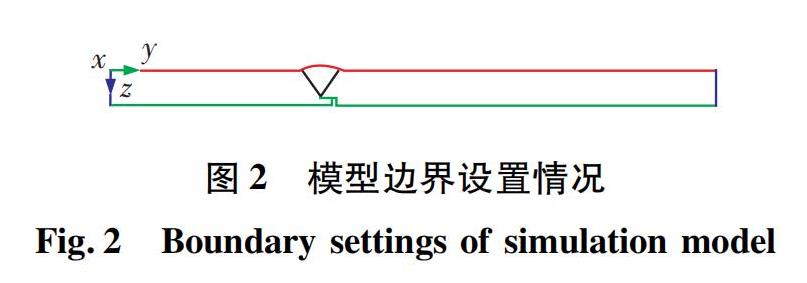

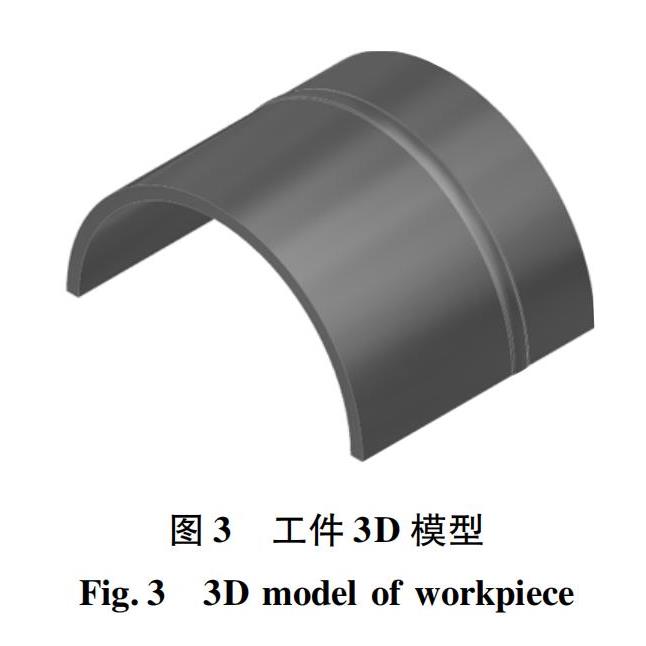

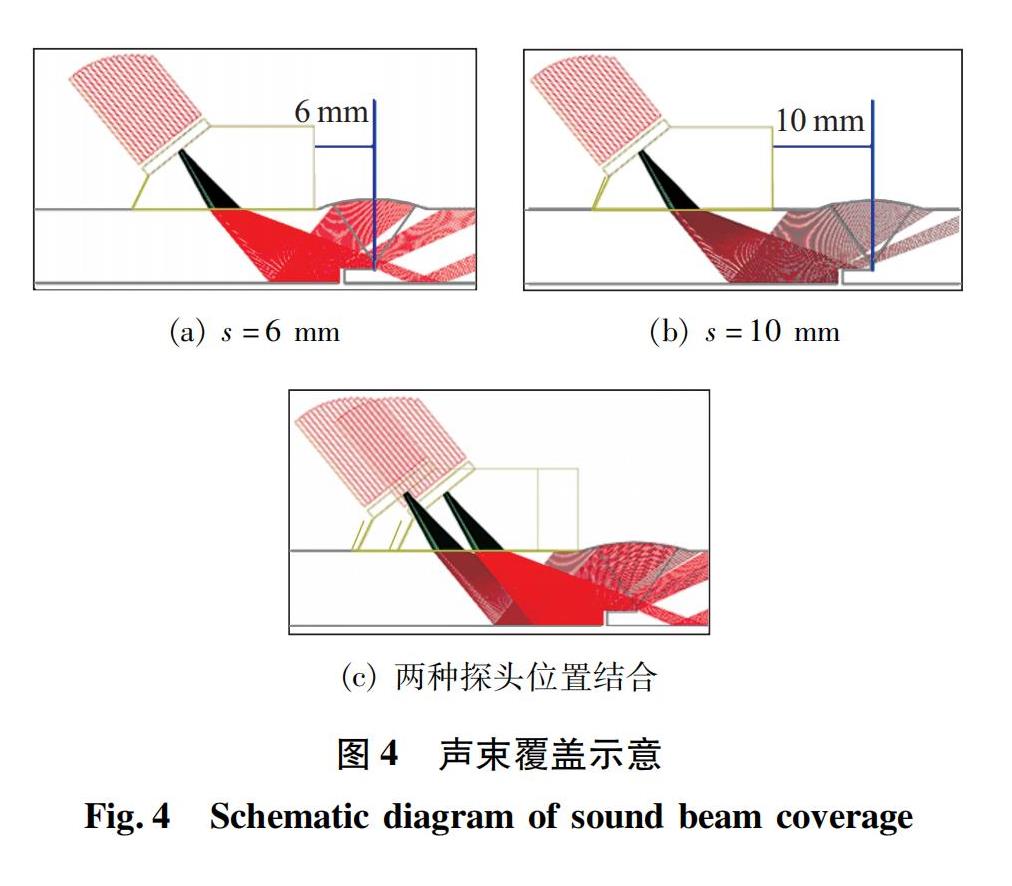

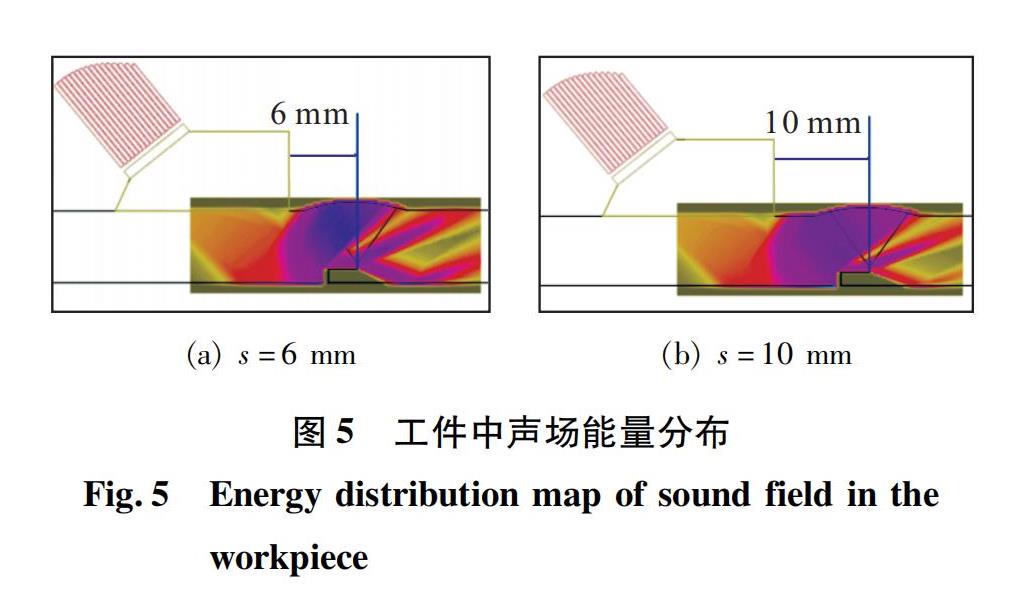

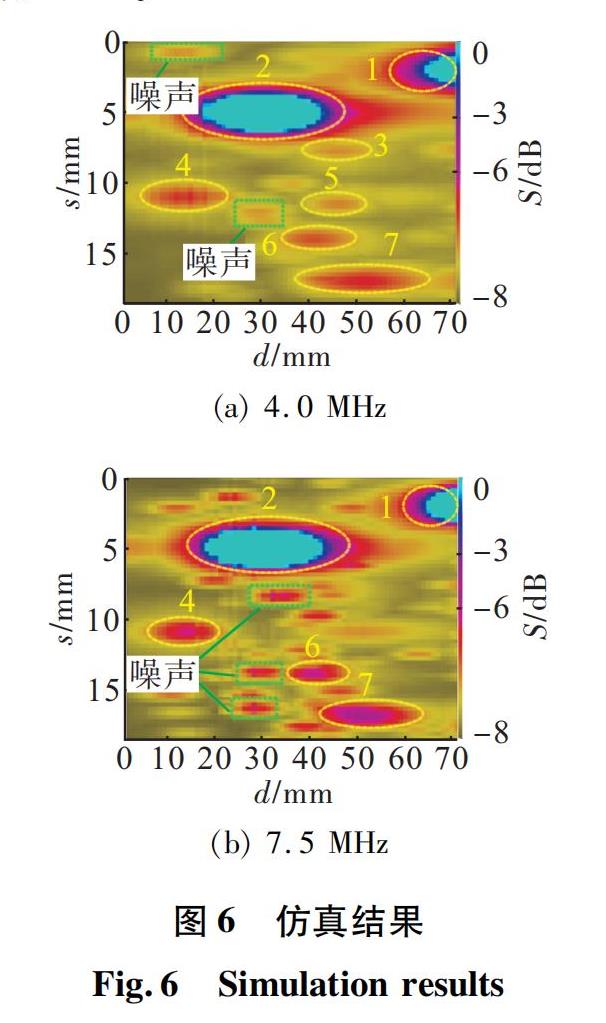

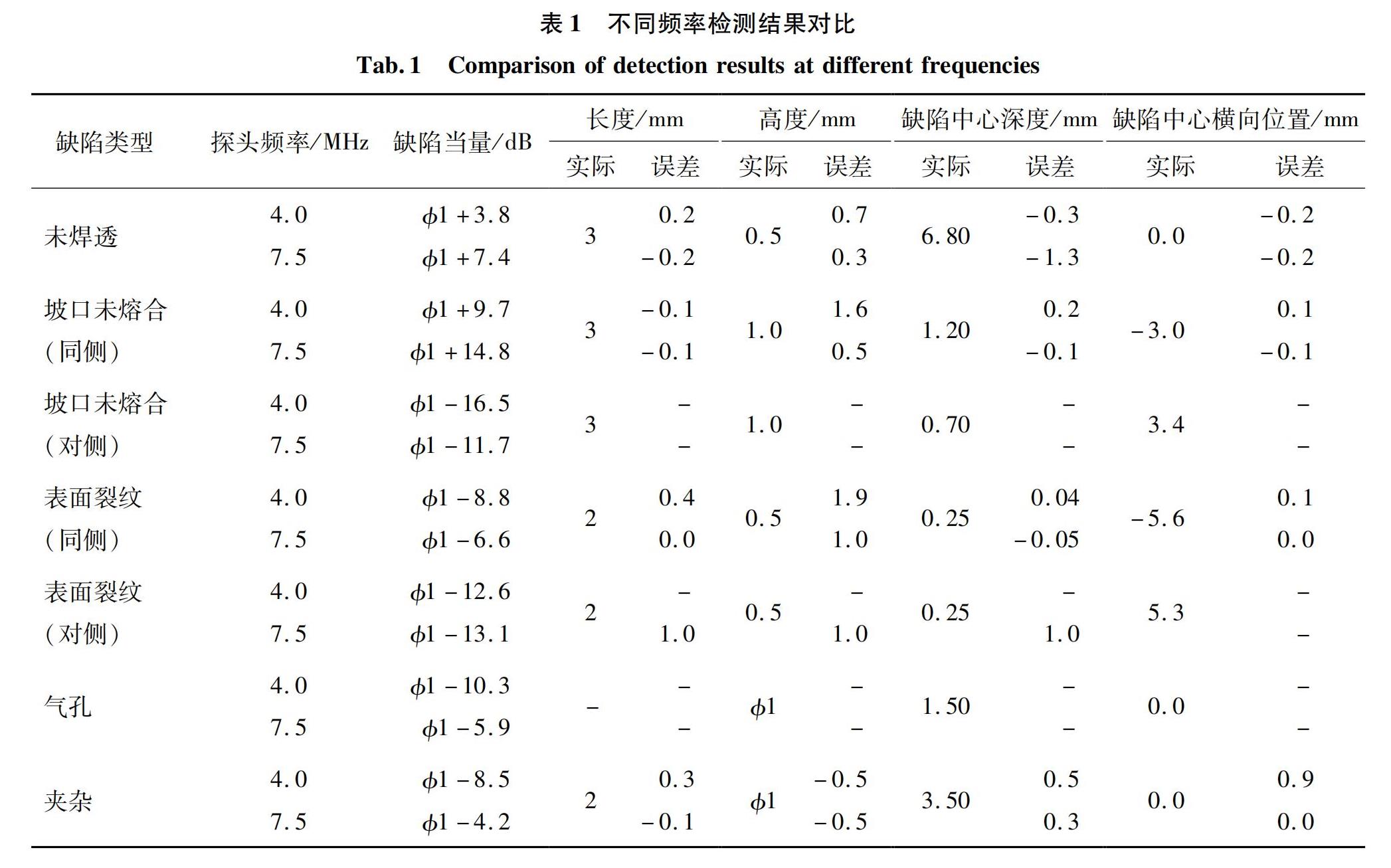

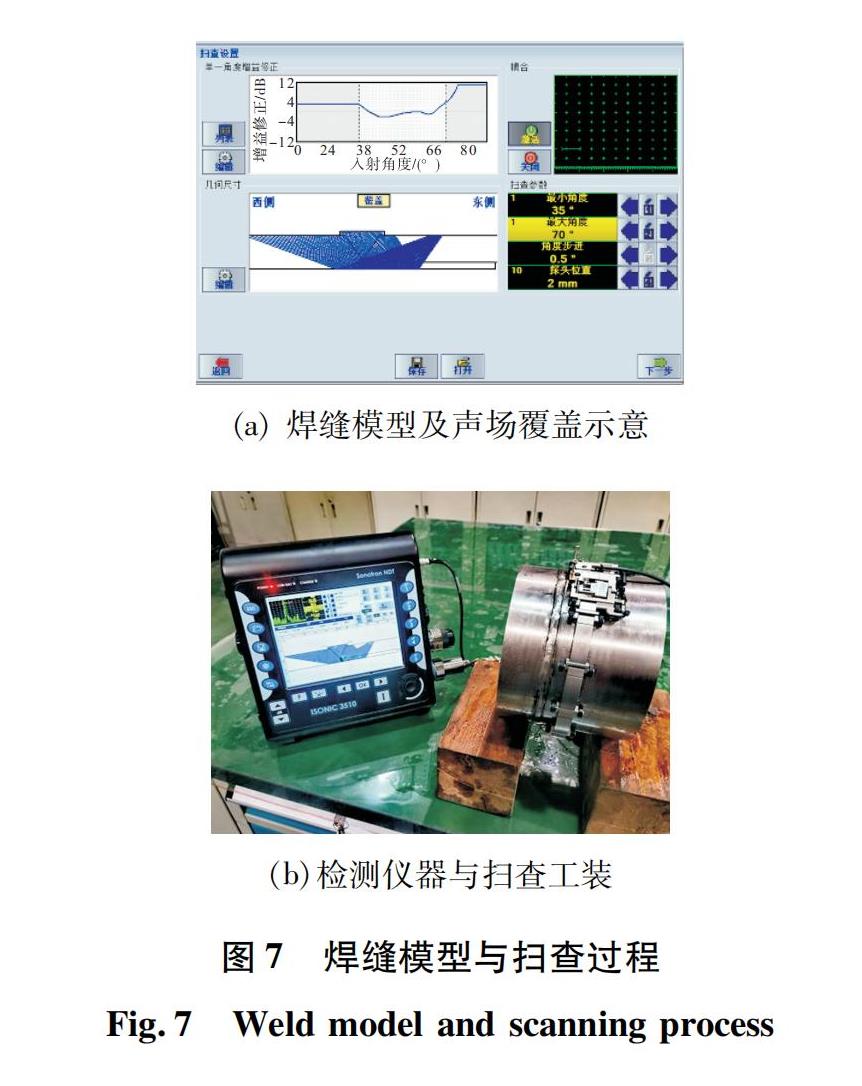

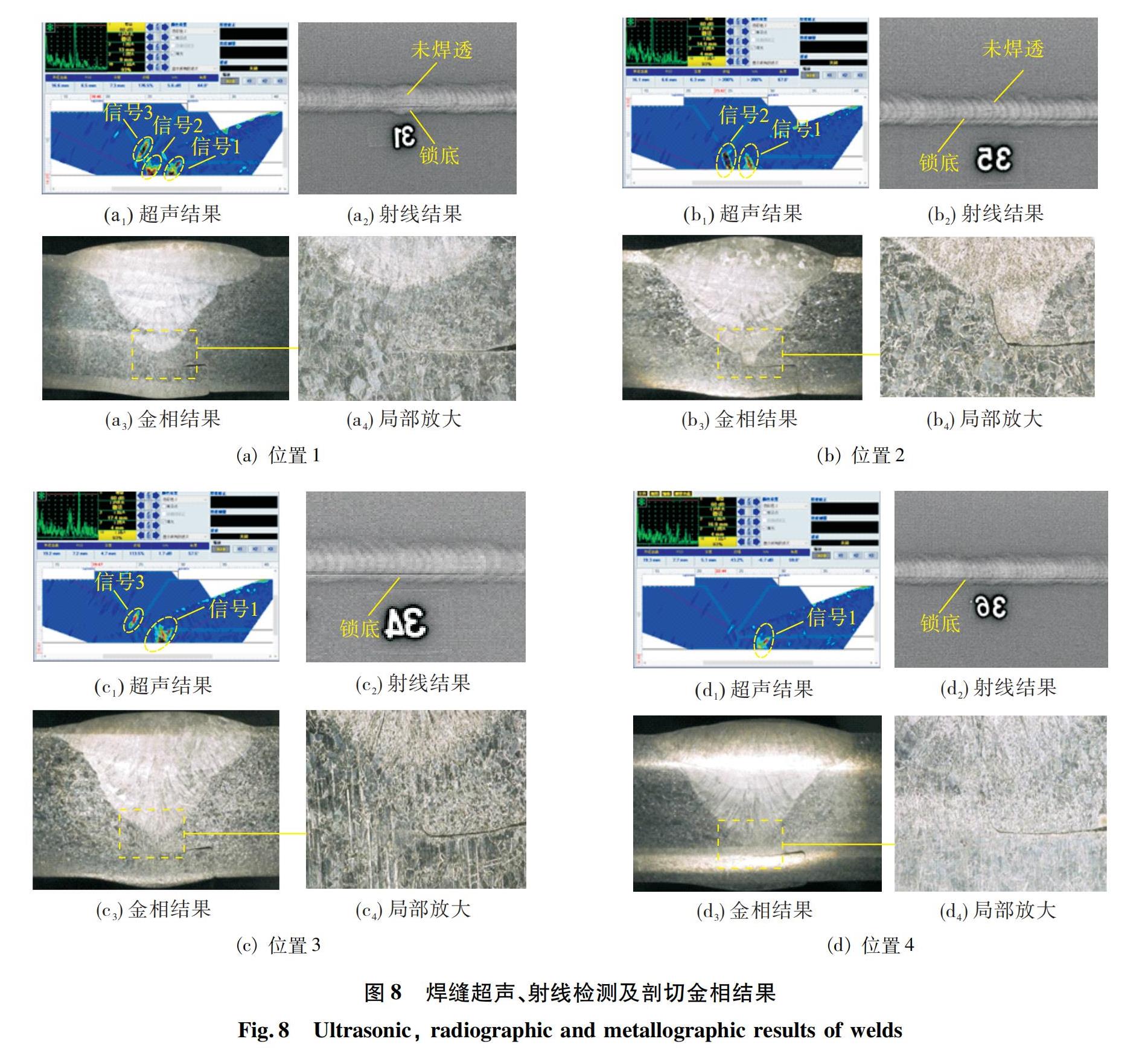

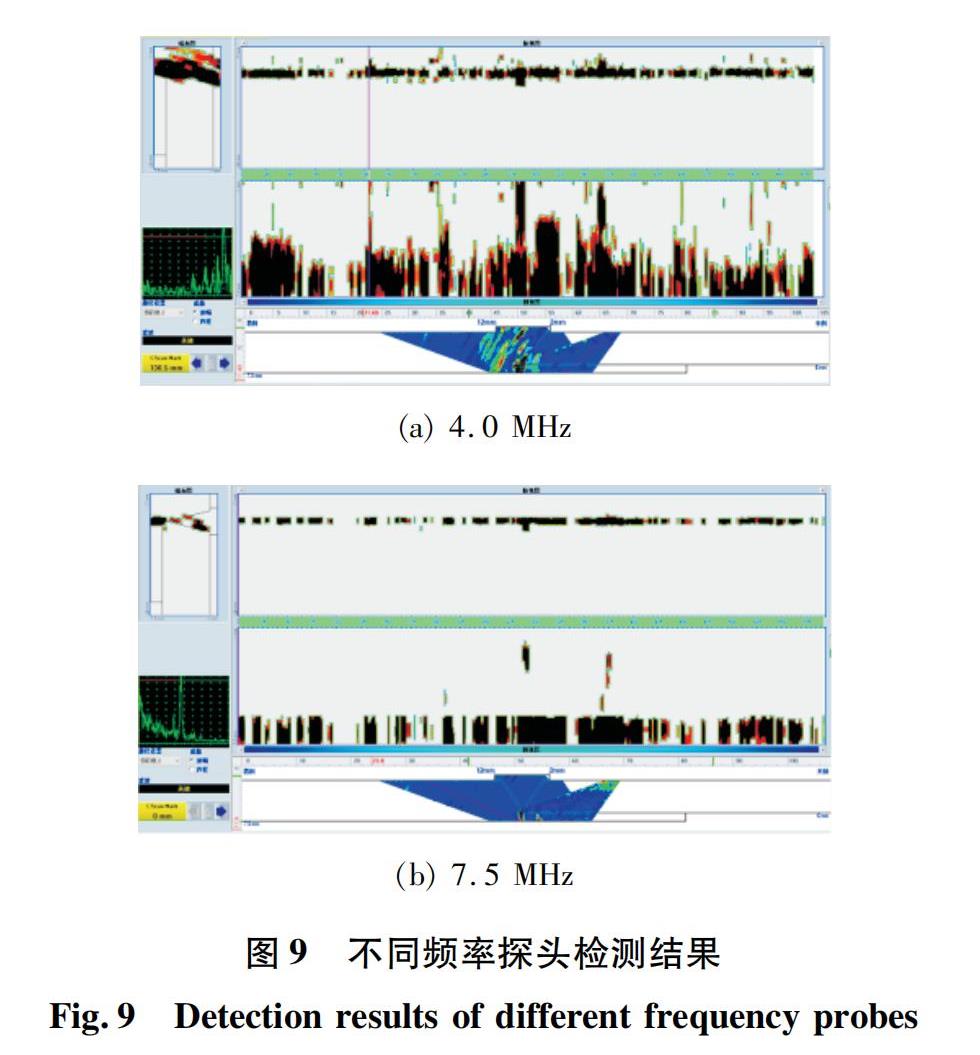

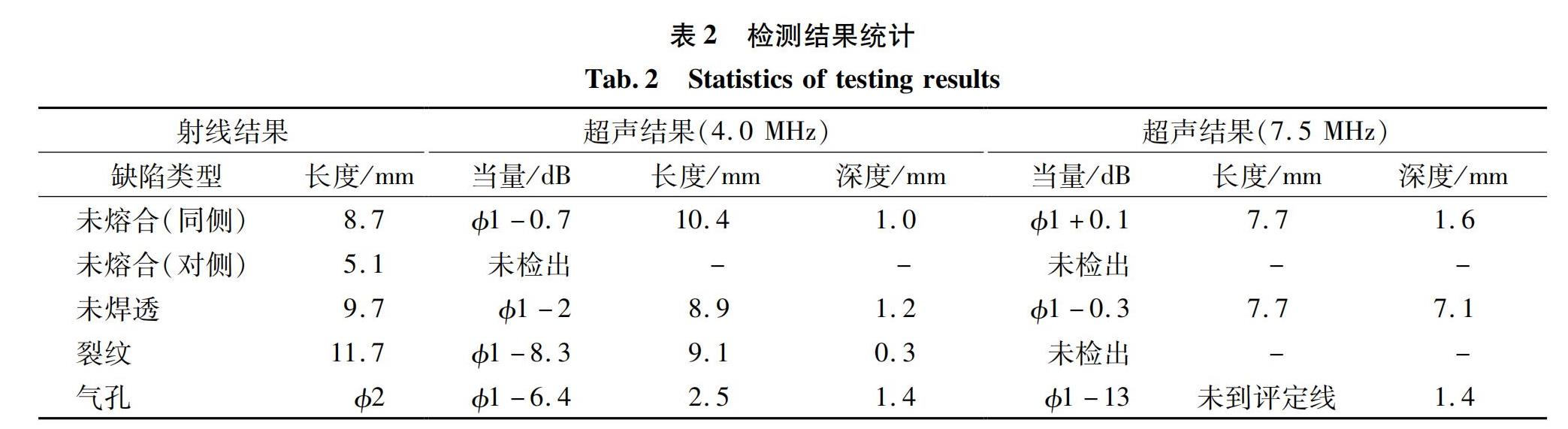

针对锁底结构X射线不可检焊缝开展相控阵超声检测技术研究。通过相控阵超声声线与声场仿真分析,确定了合理的扫查方式。对比了4.0 MHz和7.5 MHz探头的检测信噪比及缺陷响应情况,结果表明:高频探头的检测分辨力与缺陷尺寸测量精度较高; 对于粗晶材料,低频探头比高频探头具有更高的缺陷检出率。通过对比超声、射线及剖切金相结果研究了锁底结构对回波信号的影响,获得了未焊透信号识别方法。利用焊接模拟样件进行工艺验证实验,实验结果表明,相控阵超声技术可有效检出除对侧坡口未熔合之外的全部缺陷,且定量结果与射线检测基本一致。采用研究获得的检测工艺累计完成多件产品检测验证,为持续优化焊接方法、改进接头坡口形式提供了参考。

Phased array ultrasonic inspection technology was carried out for the X-ray undetectable welds of bottom-locking structures. Through the simulation analysis of phased array ultrasonic sound lines and sound fields, a reasonable scanning method was determined. The signal-to-noise ratio and defect response between 4.0 MHz and 7.5 MHz probes were compared. The results show that the detection resolution and defect size measurement accuracy of high-frequency probe are relatively high. For coarse-grained materials, low-frequency probe has a higher defect detection rate than high-frequency probe. By comparing the resutls of ultrasonic, radiographic and section metallographic, the influence of the bottom-locking structure on the echo signal was investigated and the method of identifying incomplete penetration signals was obtained. The process verification experiment was carried out by using welding simulation samples. The results show that the phased array ultrasonic technology can effectively detect all the defects except the non-fusion of the opp osite side groove, and the quantitative results are basically consistent with the X-ray detection. The detection process obtained in this study has been used to complete the detection and verification of multiple products, which provides an effective reference for continuous optimization of welding methods and improvement the joint groove forms.