作者简介:王洪福(1990—),男,硕士,高级工程师,研究领域为液体火箭发动机试验系统设计。

Beijing Aerospace Propulsion Institute, Beijing 100076, China

mechanical seal; end face special pressure; automatic gas distribution; test equipment; digital test

DOI: 10.3969/j.issn.1672-9374.2024.06.009

备注

作者简介:王洪福(1990—),男,硕士,高级工程师,研究领域为液体火箭发动机试验系统设计。

引言

静环组件与动环配合组成机械密封,膜盒式机械密封应用于液体火箭发动机涡轮泵中,其具有泄漏小的优势,可适应高低温、氧化、腐蚀等环境。高可靠性的涡轮泵对机械密封的端面比压的性能要求较高:端面比压较小会导致泄漏量大、燃料不足,过大会摩擦生热、导致异常磨损减少寿命,都会引起密封作用失效导致发射失败[1-2]。因此,机械密封的端面比压是衡量密封性能的重要指标。

机械密封的端面比压是由介质腔的压力和膜盒压缩力综合作用的结果[3]。近年采用仿真技术研究端面比压的影响因素[4-6]的较多,研究机械密封端面比压测试技术的相对较少。孙见君等[7]采用研制的试验装置可动态测量机械密封的端面比压。王财生[8]设计了一套可调节式弹簧比压测量装置。姚翠翠[9]以船舶尾轴机械密封为研究对象,建立了端面比压数学模型,对密封环的温度场、位移变化量、泄漏量等因素进行理论分析,并设计了一套密封试验系统进行试验验证。蓝箭航天空间科技股份有限公司的张小平等[10]研制了一种用于涡轮泵的可调控密封装置,通过使用不同压力值的气源作用于轴向力加载器来实现调控密封端面比压。

以上针对机械密封端面比压的研究,主要是针对机械密封在线测量以及膜盒的弹簧比压测量方面,而针对机械密封的端面比压离线测量及数字化测量方面的研究相对较少。本文主要针对机械密封的端面比压离线数字化测量进行研究。与在线测量方式相比,离线测量技术具有低成本、周期短的优势。

1 整体测试方案

液体火箭发动机机械密封端面比压数字化测试系统的技术路线如图1所示。针对机械密封产品的自由高以及安装空间的测量采取数字化的测量技术; 试验过程中采用自动调节机械密封的压缩量、自动压紧静环组件的方案,以提高端面比压测量的效率; 配气系统采用自动化配气方案,提高了配气的精度; 测控系统融合产品数字化测量,并与自动压紧系统、自动调节压缩量系统、自动配气实现集成协同控制。

图1 机械密封静环组件端面比压数字化测试系统技术路线

Fig.1 Technical route of digital test system for end face specific pressure of mechanical seal stationary ring components机械密封端面比压的试验流程图如图2所示。首先进行产品的尺寸测量并确定端面比压的压缩量; 然后安装轴系及静环组件并压紧,调整轴系位置确保压缩量,充气腔充压并调节不同压力并进行端面比压测量; 最后撤气并返回各系统初始状态。

2 端面比压测量方法

2.1 端面比压测量理论基础机械密封中静环组件为外压型接触式膜盒结构,如图3所示。

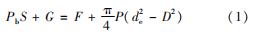

对轴系进行受力分析,可得

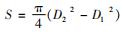

式中:Pb为端面比压; S为静环组件石墨凸台的面积,

; G为轴系自重; F为轴系轴向力; P为介质压力; D为轴系的直径; de为膜盒的平衡直径。

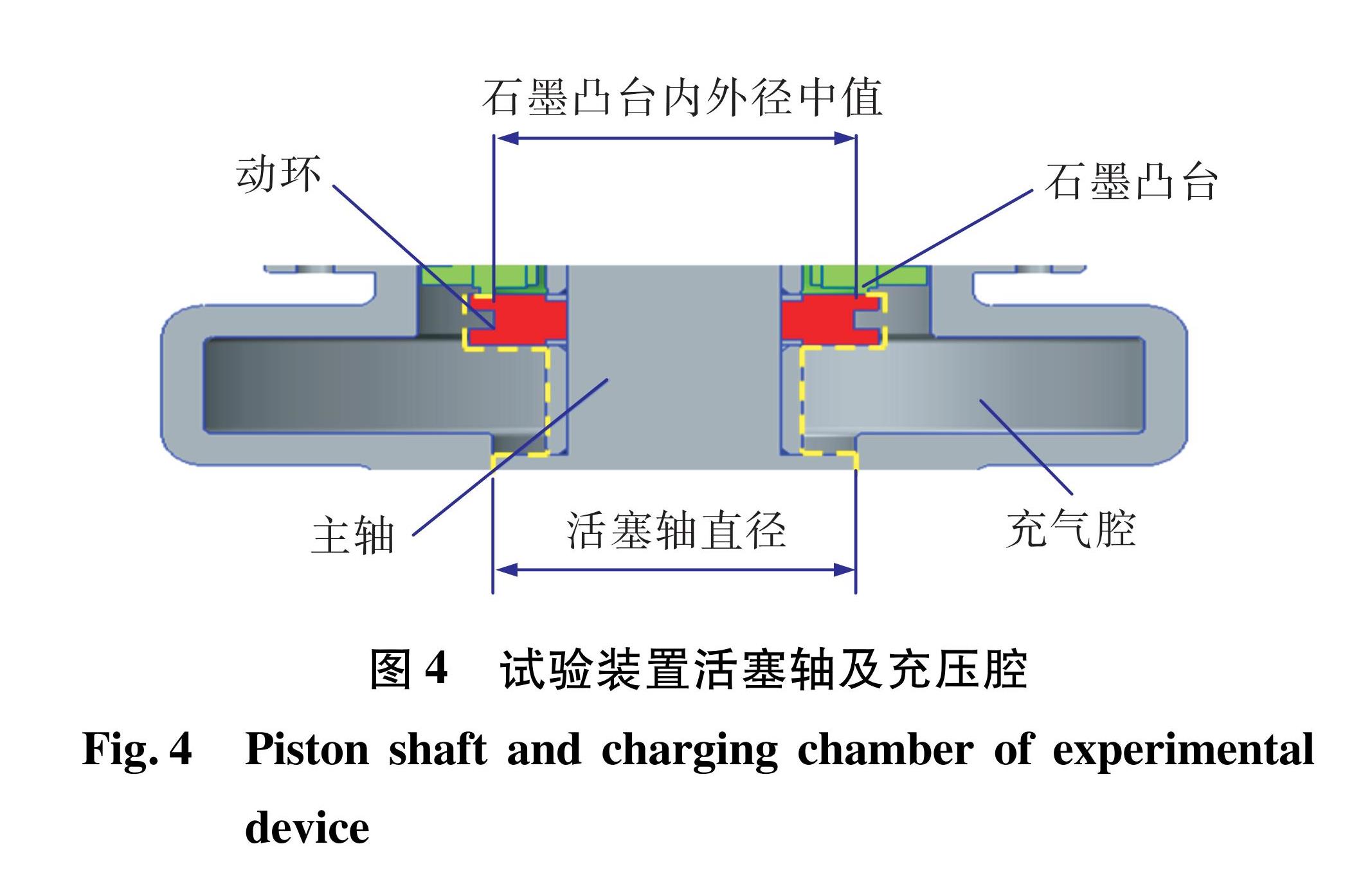

; G为轴系自重; F为轴系轴向力; P为介质压力; D为轴系的直径; de为膜盒的平衡直径。为了简化计算和平衡轴系受介质的作用力,将介质作用的主轴设计成一个活塞轴; 但膜盒的平衡直径无统一公式,本文拟采用最简单、最常用的计算方法de=(D1+D2)/2[3],设计活塞直径与膜盒的平衡直径相等,即D=de; 同时,轴系自重可在传感器设置零点消除,则式(1)可简化为PbS=F。若采用其他膜盒的平衡直径或不设置活塞轴,则可根据式(1)进行相应计算。

2.2 产品数字化测量技术在进行试验前,需要对静环组件的自由高度、静环组件安装面距动环的距离进行测量。为了提高测量效率,采用数字化测量解决方案。产品数字测量技术可消除纸质化记录,将测量数据同步至测量系统。采用测量仪器(高度尺、深度尺)对静环组件的自由高度、静环组件安装面距动环的距离进行测量,其测量数据可以通过通信系统进行数据传输,数据测量完成后按下确认键,数据将自动传输至计算机中。

该技术采用基于IEEE802.15.4(2.4 GHz)的专有通信[11],保证了数据传输的可靠性、稳定性及安全性。该系统具有扩展性、通信距离远、通信寿命长、尺寸小、 质量轻的特点,满足机械密封端面比压测量需求。

2.3 试验装置设计静环组件为外压型接触式膜盒结构,为保证充压后轴系受力平衡,设计了与密封石墨凸台等效的平衡活塞轴,如图4所示。活塞轴与壳体小间隙配合减小介质的泄漏,此外为了使试验装置的压力更稳定,采用充气腔扁平化设计,增大了充气腔的体积。此外,为了使测量过程中气体压力的稳定性,在管路系统中增加一个2 MPa、2 L的缓冲气瓶。

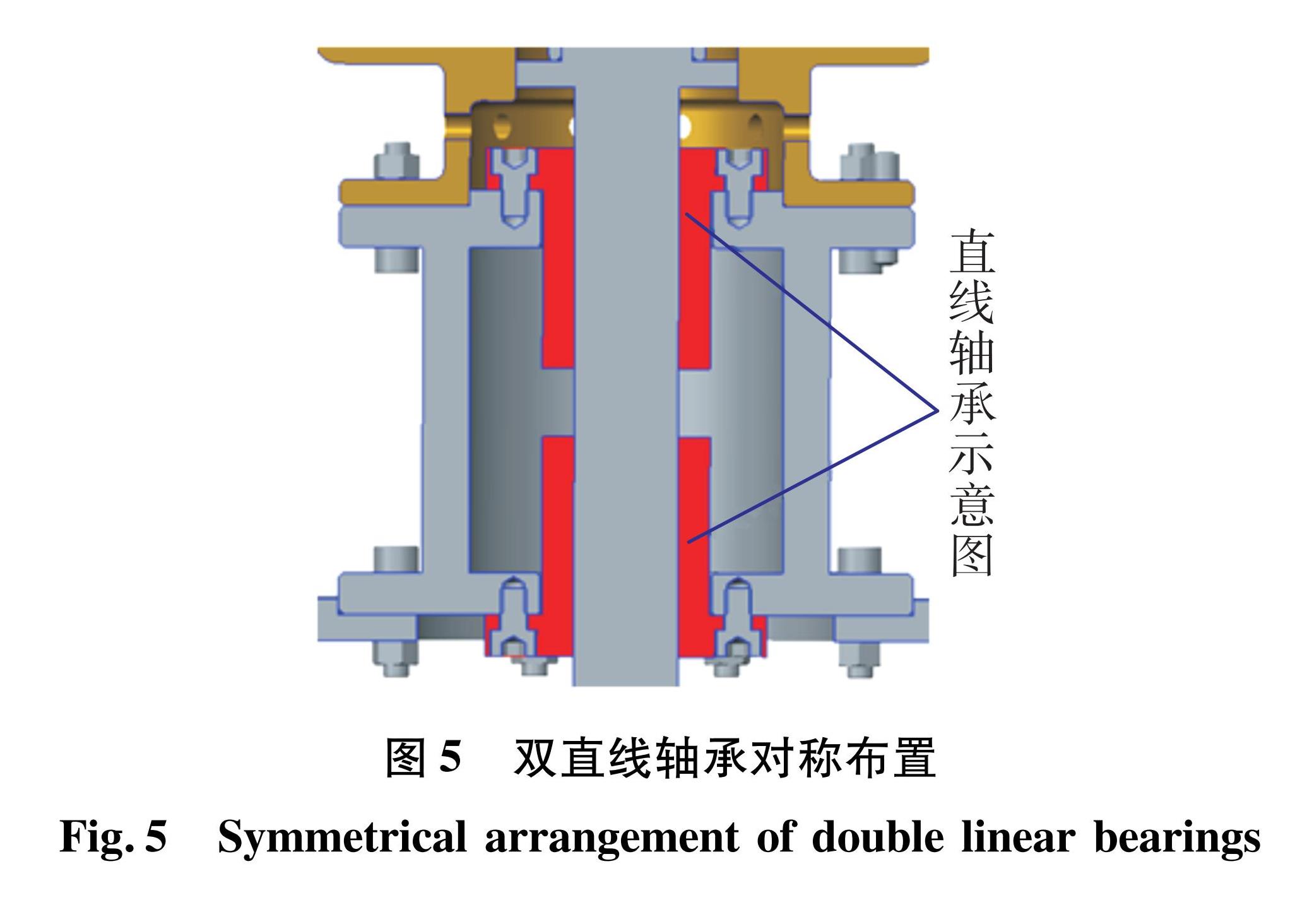

为了保证轴系的径向偏斜量尽量控制在0.05 mm范围内,确保端面比压测量的可靠性,试验装置的主轴采用两个直线轴承对称布置安装,达到了与主轴的精密配合,同时主轴的上下移动可实现静环组件压缩量的调整,如图5所示[12-13]。

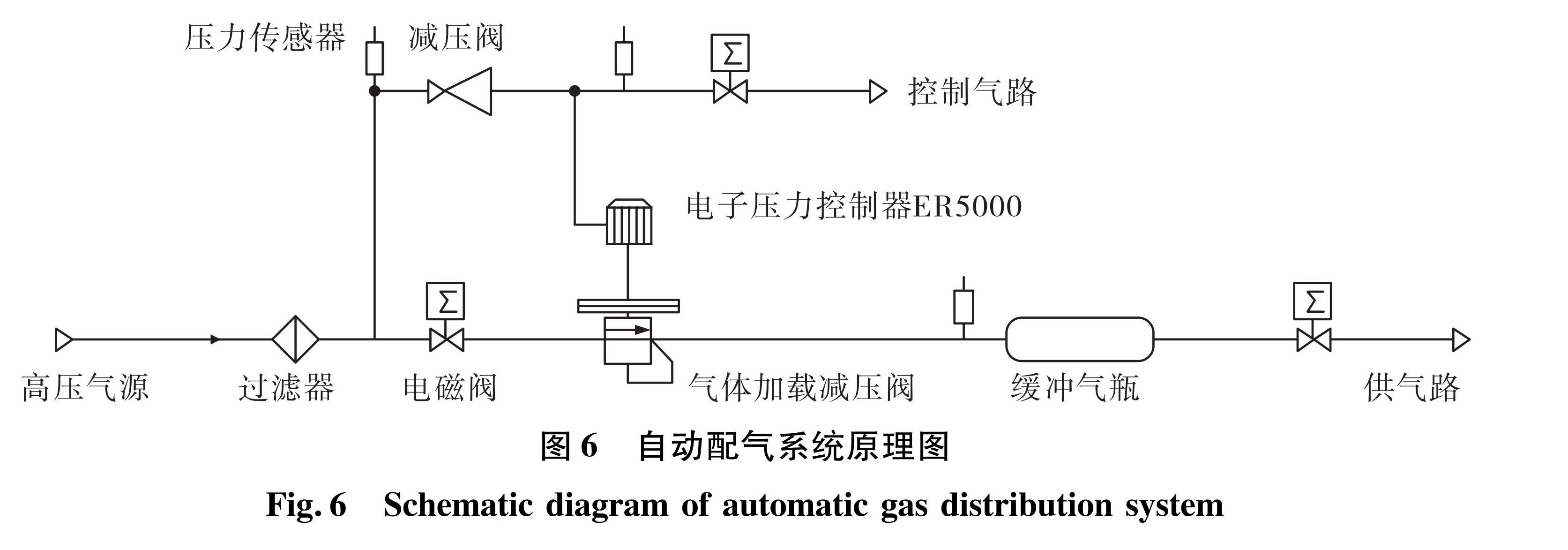

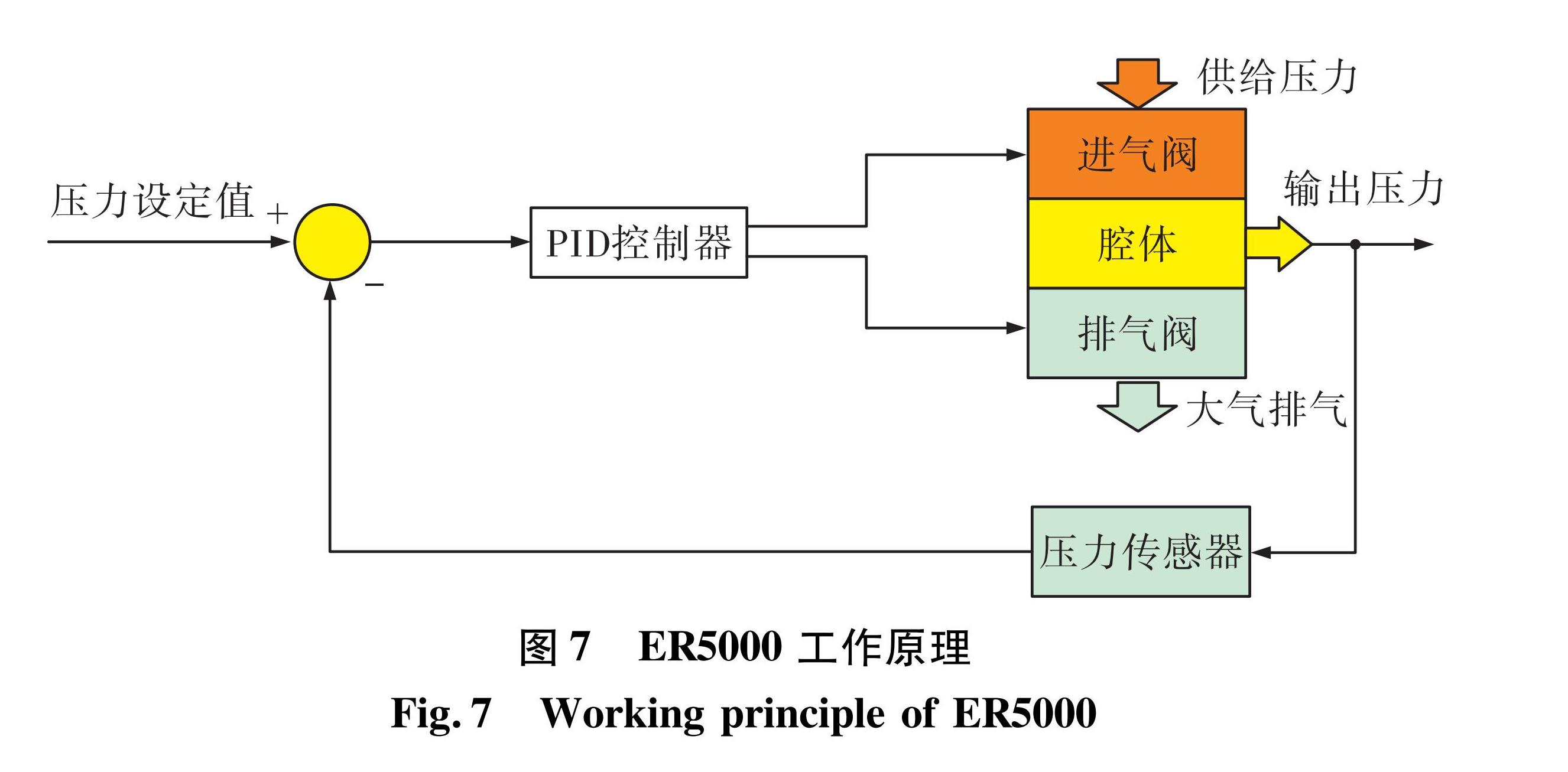

自动配气系统实现试验过程的配气自动化,系统可根据使用压力值设置参数,通过自动控制方式调节气控减压阀,为下游用气提供稳定可靠的压力源,可满足试验过程压力的自动增压及减压的自动化处理,提高精度和试验效率。采用电子压力控制器+气体加载式减压阀形式,通过电子压力控制器输出不同控制气压力来调整减压阀出口压力,同时为提高出口压力调整精度,在减压阀下游配置有2 L的缓冲气瓶。配气系统的原理图如图6所示,其中核心部件采用TESCOM的基于PID控制(比例-积分-微分)的电子调压器ER5000进行压力调节。ER5000是一种多功能集成式的压力控制器,集成了压力传感器、PID控制器和电动比例阀这3个部件,集传感器、控制器和电子阀门于一体构成一个完整的控制机构[14-16]。

TESCOM的气体加载式减压阀最大入口压力10 000 PSI(约70 MPa),输出压力为5~400 PSI(约0.034~2.760 MPa),输出压力与控制气压力升压比为5:1; TESCOM的电子压力控制器ER5000用于控制气输出,控制气压力调节精度为±0.1%,因此减压阀输出压力最终理论最大偏差为±0.014 MPa(±0.1%×5×2.760 MPa),可满足自动配气对调节精度的要求。试验系统的气路原理图如图7所示。

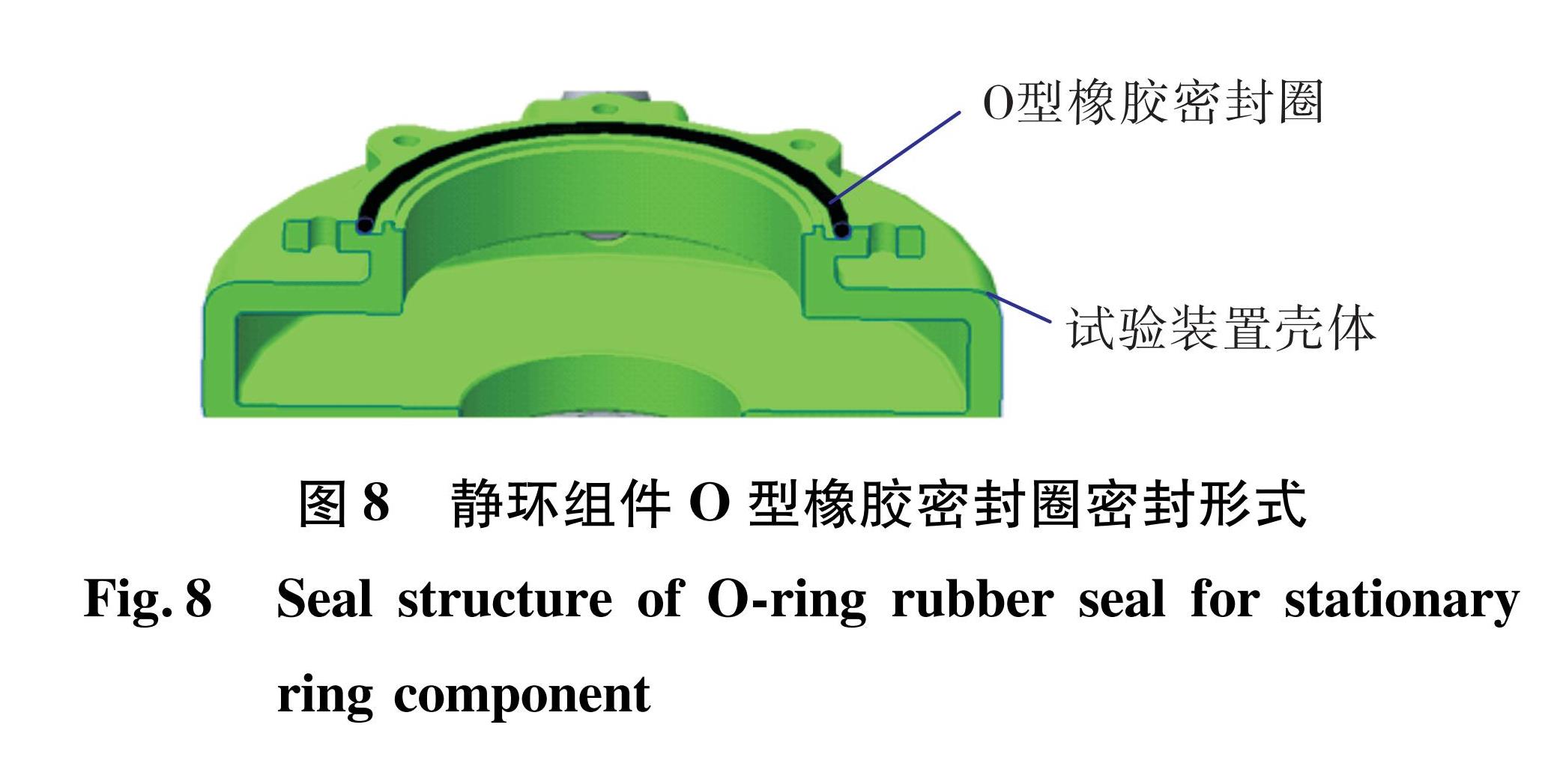

2.5 自动压紧技术静环组件采用8个螺钉与壳体进行连接,安装和拆卸都需要进行螺钉拆卸,劳动强度大。为了减少拆卸、安装静环组件的劳动强度,采用自动压紧装置-静环组件-O型橡胶密封圈的方案进行密封,整体方案如图8所示。自动压紧装置将自动升降装置的力传递到静环组件上,静环组件可压紧O型圈,从而实现快速自动压紧密封功能。快速压紧装置方案采用电机驱动,可控制升降速度及位移,到达指定位置实现自锁,同时采用力传感器监控加载力的大小。

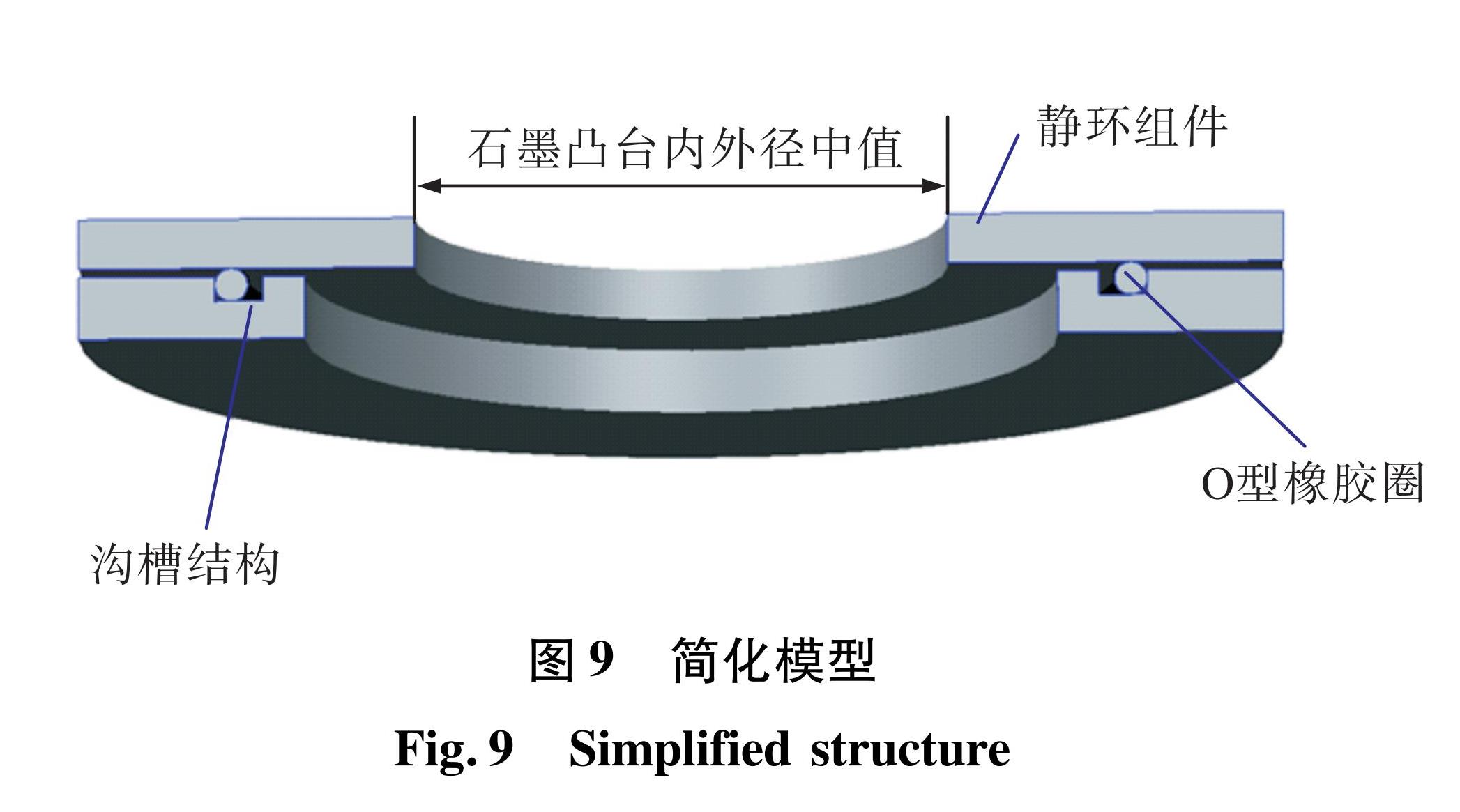

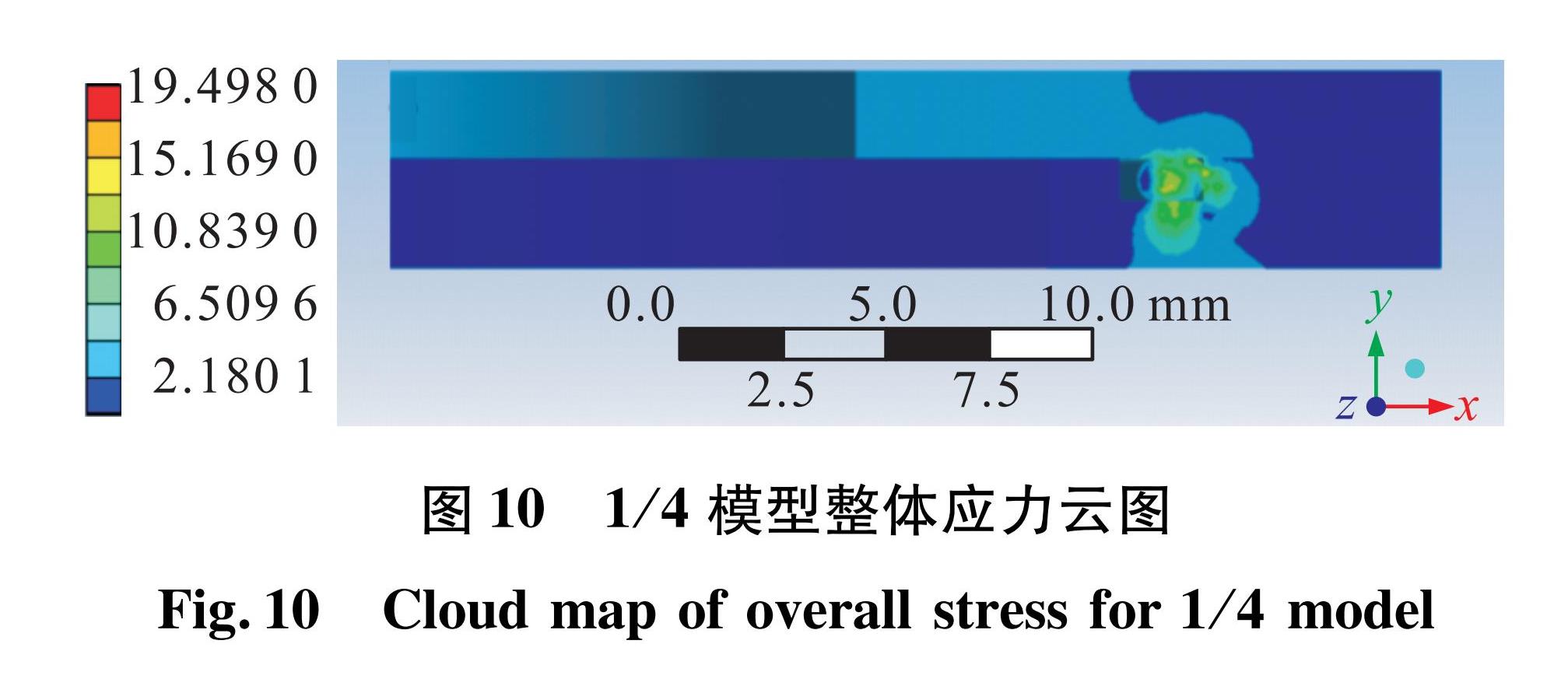

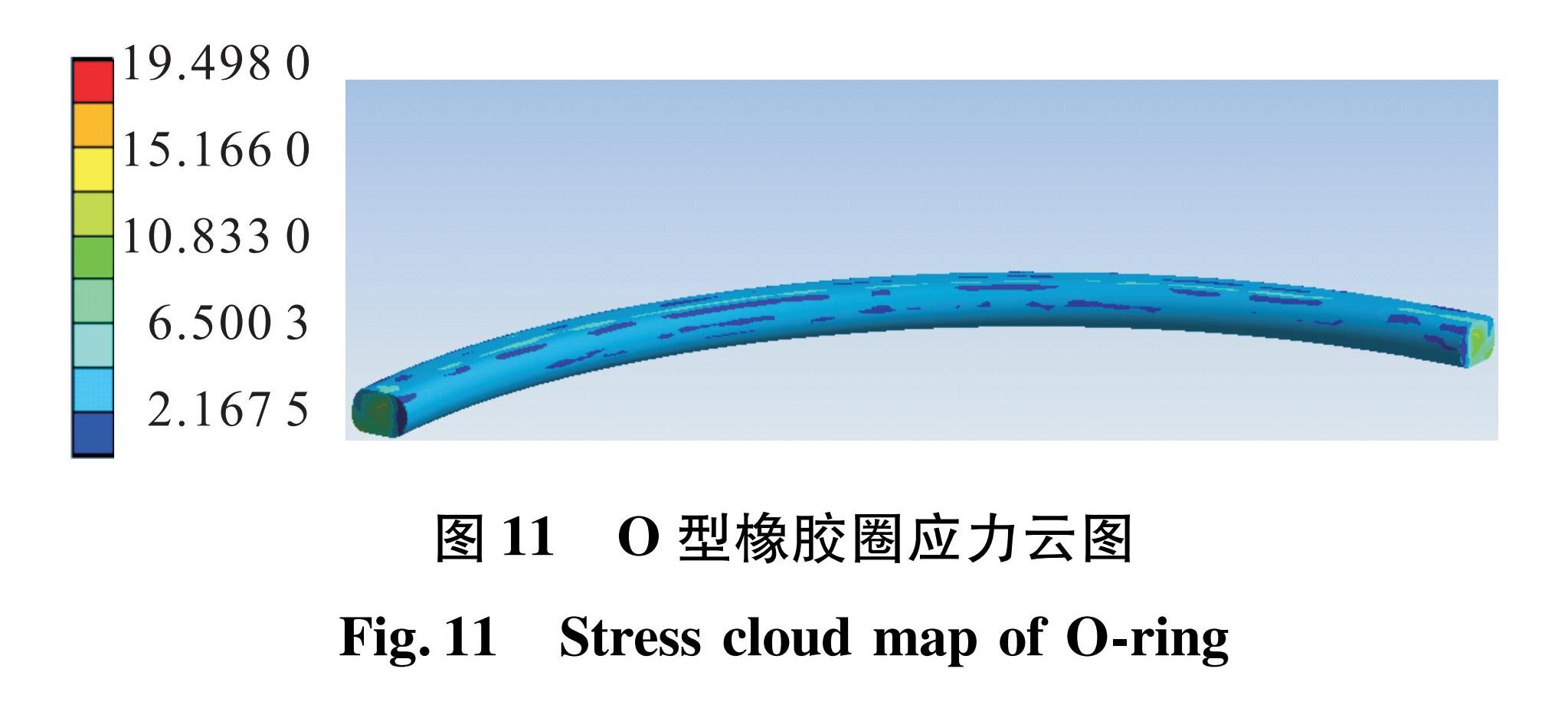

为了确定自动压紧装置的可行性,需要计算压紧O型橡胶圈所需要的力,利用ANSYS Workbench对其进行仿真分析。对试验装置、静环组件进行简化,构建三维模型,如图9所示。对O型橡胶圈的橡胶材料进行定义,设置Mooney-Rivlin橡胶模型的硬度、弹性模量[17-18]; 设置接触,将橡胶与不锈钢之间的摩擦因数调为0.9; 并设置试验装置为固定支撑,静环组件位移约束,将O型橡胶圈压平,以保证静环组件的密封; 静环组件的内部气体压力1.5 MPa(预留试验能力)。整体应力云和O型圈应力云图分别如图 10和图 11所示,对比可知最大应力发生在O型橡胶圈上,为19.498 MPa。模型的支反力将O型橡胶圈压平,所需要的压紧力为2.111 5 kN。

2.6 自动调节压缩量技术静环组件与试验装置的外壳相连接作为静止件,动环安装在主轴上,并与静环组件接触,随轴系上下移动件,从而实现静环组件的不同压缩量。为了更加便捷地调整静环组件的压缩量,采取自动调节压缩量装置,带动测力传感器及轴系的上下移动,从而调整动环与静环组件的压缩量。自动调节压缩量选取电机、滚珠丝杠、光栅尺的闭环控制方案。

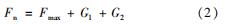

为了确定自动调节压缩量装置的可行性,需要计算自动调节压缩量装置在测试环节所承载的最大受力。

式中:Fn为自动调节压缩量装置最大受力; Fmax为某型号静环组件最大端面受力; G1为轴系的重力; G2为测力传感器的重力。

根据所选定的机械密封,Fn计算结果为500 N。电机的最大承载质量满足系统负载的需求。

自动调节压缩量技术采用高精度微调步进电机带动交叉滚珠导轨,实现运动平台的升降; 选择闭环控制方法,利用光栅尺对平台移动的位移进行精确测量,将位移信号反馈至驱动器,实现位置的精确控制。高细分步进电机驱动分辨率高达0.125 μm,平台的重复定位精度不大于5 μm。

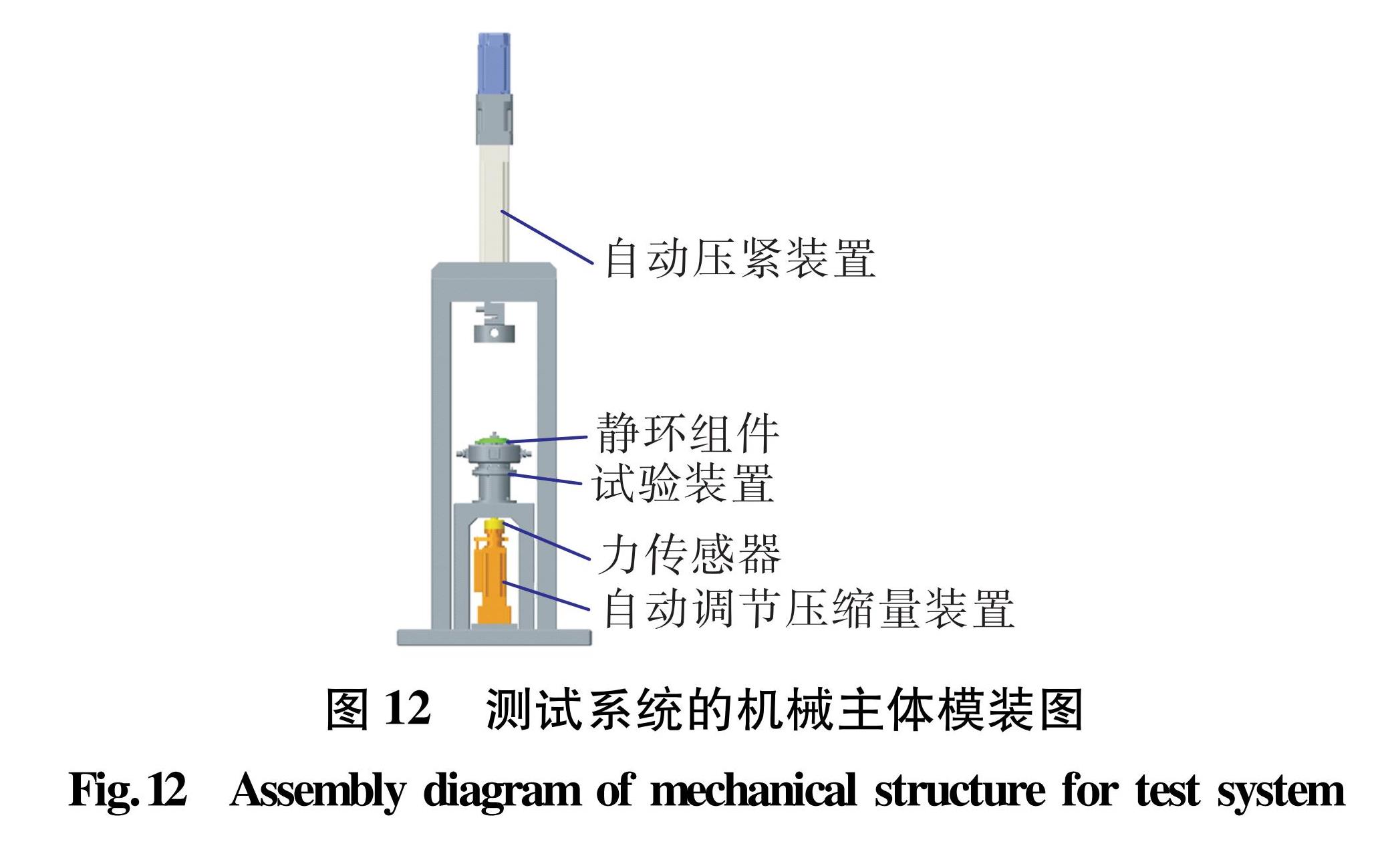

此方案可在不重新拆卸轴系的情况下对静环组件的压缩量进行调整。根据自动调节压缩量以及自动压紧装置的可行性分析,完善了测试的试验装置模装图,如图 12所示。

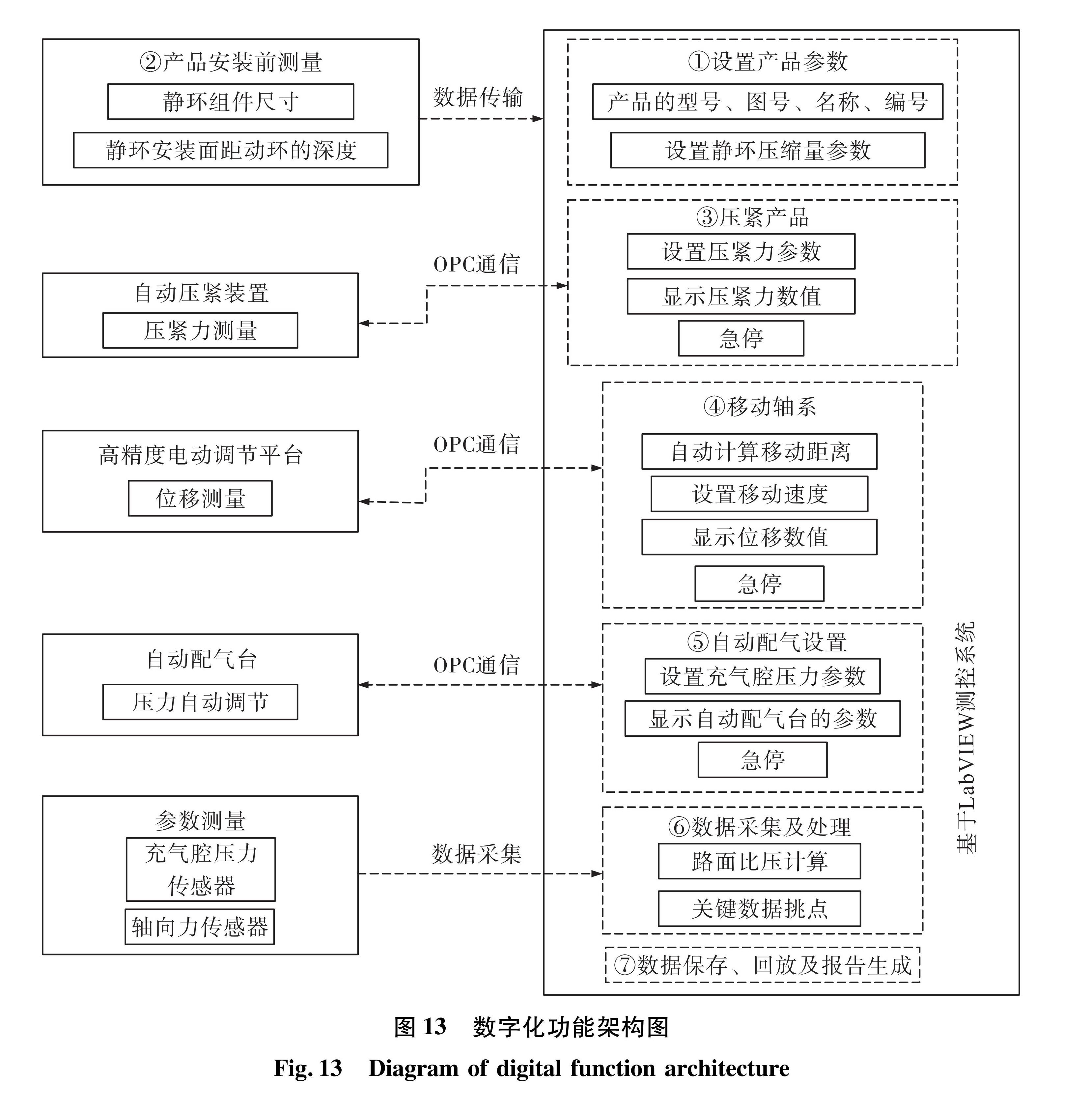

2.7 测控系统构架机械密封端面比压数字化测试系统主要针对影响整个测量流程中的关键环节提出数字化的解决方案,主要针对产品测量环节、试验装置中静环组件的固定以及调整动环位移环节、自动配气系统调节充气腔压力以及基于LabVIEW的测控、报告系统。

控制系统是实现自动调节压缩量装置、自动压紧装置以及自动配气系统的协调。自动调节压缩量装置可实现静环组件压缩量的精确调整,其原理为根据压缩量试验数值,以及产品数字化测量的静环组件自由高、静环组件安装面距动环的距离,上位机软件可自动计算高精度电动调节平台的需升降的位移量,通过OPC(object linking and embedding for process control)通信发出指令完成高精度电动调节平台的升降。自动压紧装置可实现对静环组件-O型圈的压紧从而实现密封作用,还具备施加轴向力的测量功能,为轴向力的监测提供数据支持。自动配气系统实现试验过程的配气自动化,满足试验过程压力的自动增压及减压的自动化处理,提高精度和试验效率[19-20]。

测控系统主要对充气腔的压力及轴向力进行测量、记录,并将产品装配记录及试验数据自动存储到试验数据库系统。

基于LabVIEW的上位机软件的数字化功能架构如图 13所示。

3 实验验证及讨论

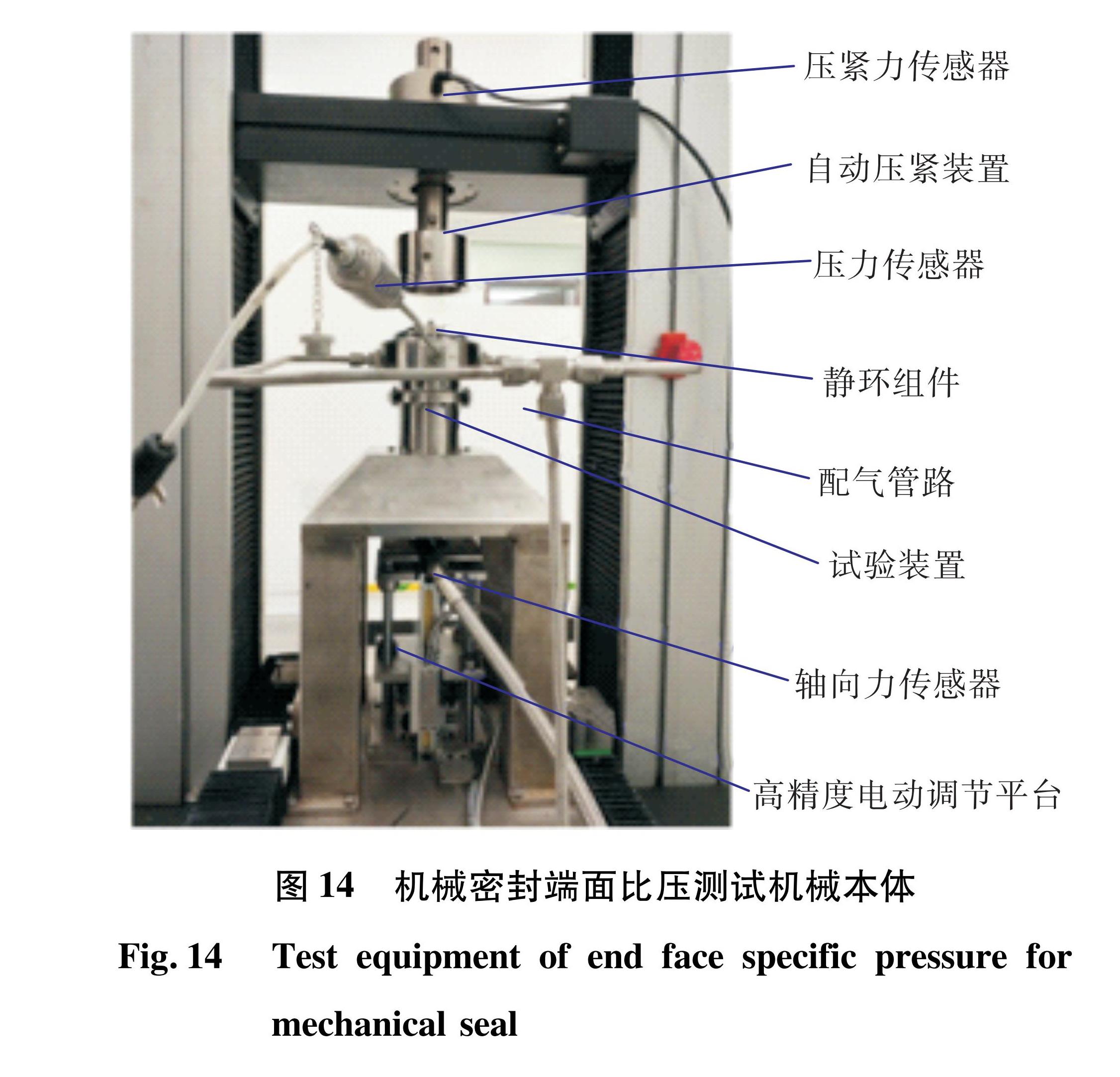

通过对数字化测试技术的研究,最终形成机械密封端面比压数字化测试系统,其机械本体如图 14所示。自动压紧技术采用龙门式电驱动的自动压紧装置,自动调节压缩量系统采用电机+滚珠丝杠+光栅尺的闭环控制系统的高精度电动调节平台,端面受力传感器安装在平台上; 通过不锈钢金属管路将试验装置的介质腔与自动配气台进行连接; 同时试验装置的轴系安装在轴向力传感器上,构成了整个机械密封端面比压的测试机械本体。

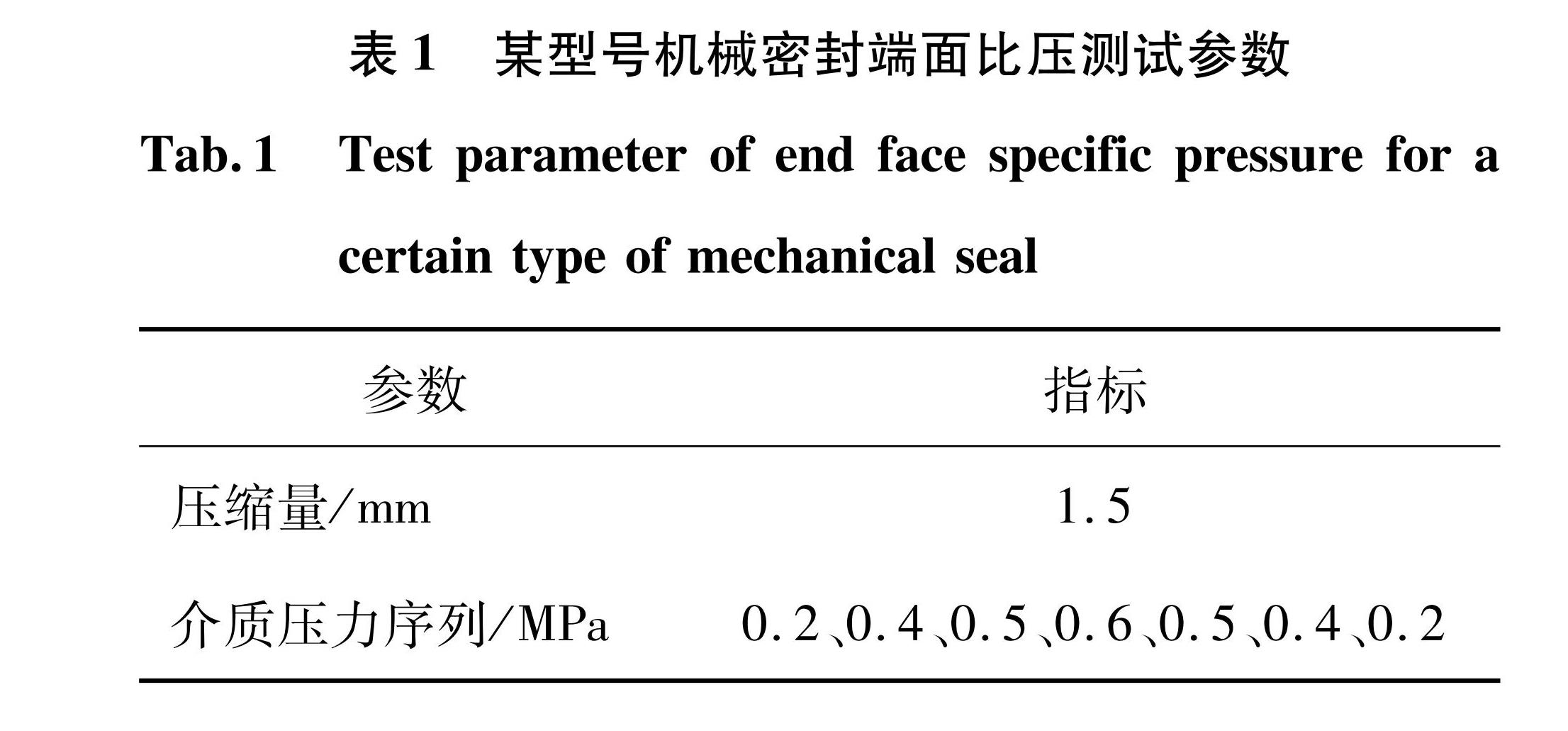

通过基于LabVIEW的测试软件进行数字化测试,对某型号产品进行阶梯式增压、降压单一压缩量的端面比压进行测试,其测试参数见表1。

表1 某型号机械密封端面比压测试参数

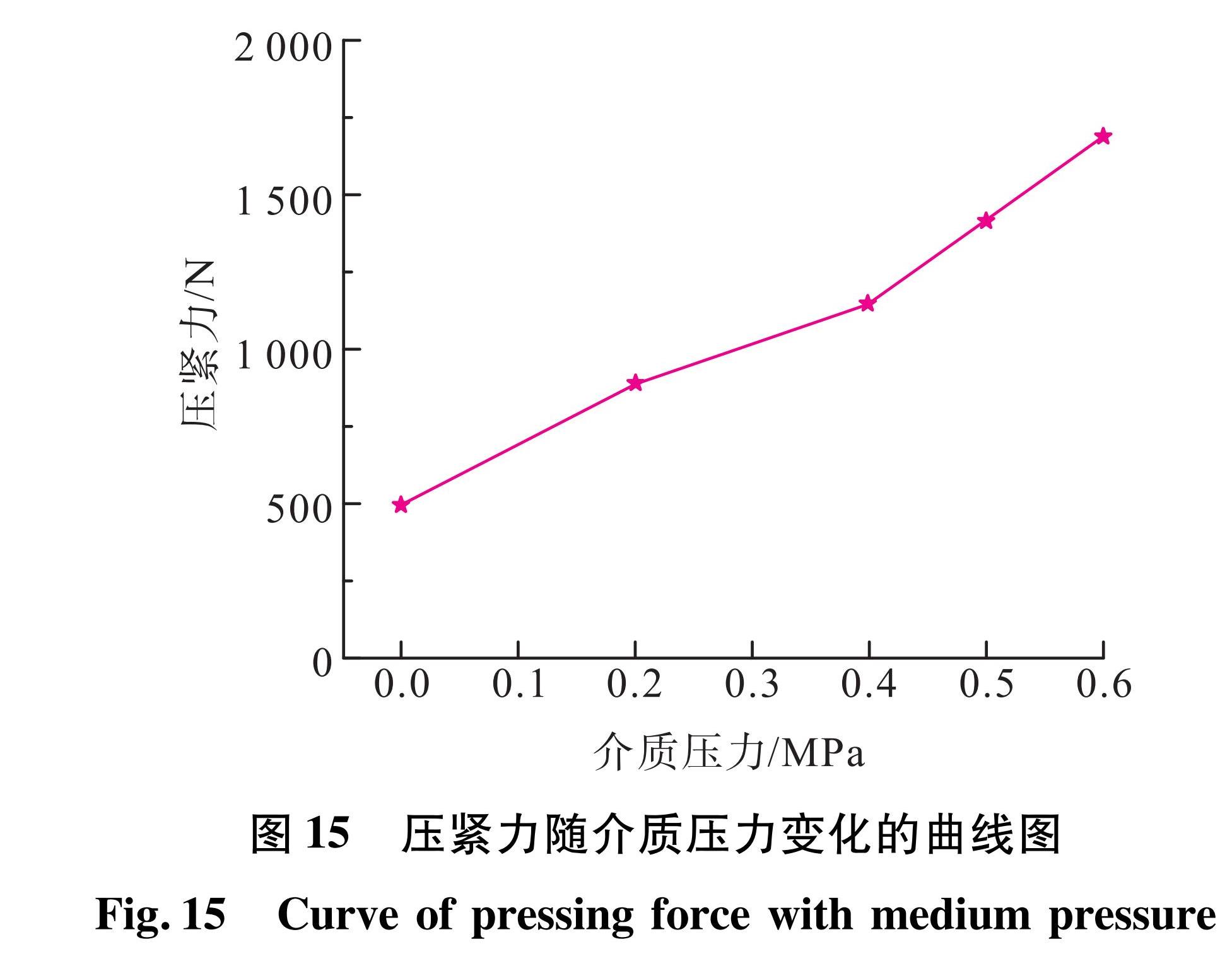

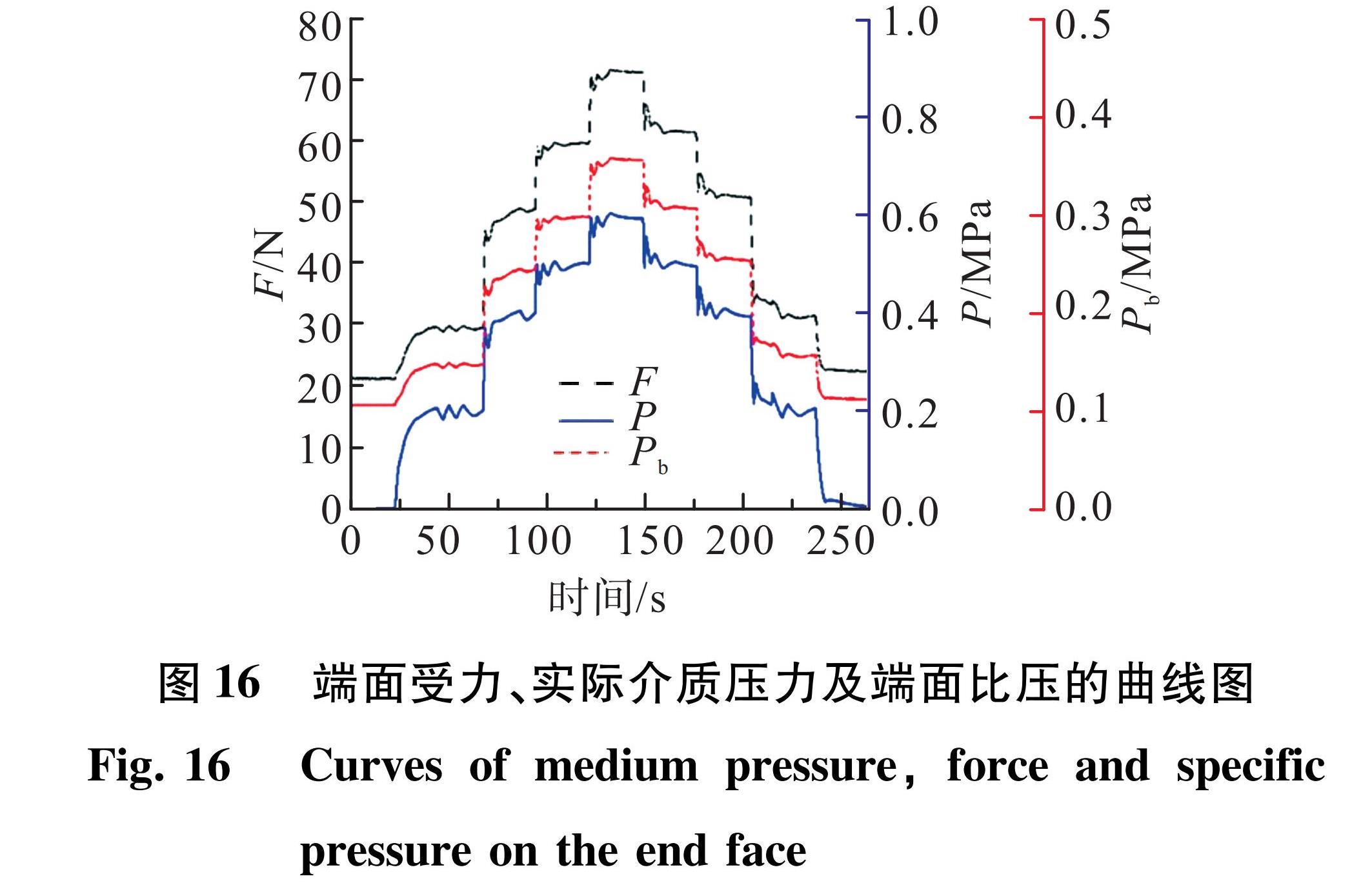

Tab.1 Test parameter of end face specific pressure for a certain type of mechanical seal测试前采用产品数字化测量技术对静环组件的自由高度、静环组件安装面距动环的距离进行测量,为验证轴系的径向偏斜量,手动旋转主轴,使其径向跳动为0.005 mm。按照测试流程进行实验,对测试过程进行监控及数据采集。图 15为压紧系统的压紧力随介质压力变化的曲线图; 图 16为端面受力、介质压力及端面比压的测试数据曲线。

图 16 端面受力、实际介质压力及端面比压的曲线图

Fig.16 Curves of medium pressure, force and specific pressure on the end face由图 15可知,自动压紧系统的压紧力随介质压力增大而增大; 从图 16中可看出,自动配气系统在增压或减压存在较为明显的PID调节过程,但调节过程中没有超压,调节的压力范围及调节时间都较小; 端面受力随着介质压力的波动而变化,端面比压(在某压缩量下)在0.1~0.4 MPa范围内变化。

对机械密封端面比压的数字化测试系统进行整体分析,并与机械式测试结果进行对比,结果如表2所示。

通过对两种测试方案进行对比,采用数字化测试技术解决压缩量精度、介质压力调节精度的问题较采用传统机械式的技术手段,其参数精度得到了一定程度的提高; 同时其测试时间也大大缩短。

4 结论

1)本文对机械密封端面比压离线数字化测试系统中的关重要技术进行研究,数字化测试系统由产品数字化测量技术、试验装置设计、自动配气技术、自动压紧技术、自动调节压缩量技术以及完整的测控系统架构组成。

2)试验装置将主轴设计成活塞轴,活塞轴直径与膜盒平衡直径相等,平衡了轴系受介质的作用力,同时采用双直线轴承对称布置将轴系的偏斜量控制在0.005 mm。

3)通过仿真及实验验证,采用O型圈+自动压紧的自动压紧技术可快速将静环组件固定,利用高精度调节压缩量技术可将静环组件的压缩量精度提高到±0.005 mm,自动配气技术可为测试系统提供精度±0.02 MPa的介质。

4)本文提出的测试技术大大提高了测试的数字化程度,缩短了测试的周期,提高了测试的效率及精度,为数字化测试技术提供了一种解决方案。

- [1] 孙开元, 郝振洁. 机械密封结构图例及应用[M]. 北京: 化学工业出版社, 2017.

- [2]陈鹏飞, 尚冬琴, 周立新. 静环振动对涡轮泵端面密封失效的影响[J]. 推进技术, 2019,40(5): 1129-1135.

- [3]吴霖, 姜绪强, 李铭, 等. 压力对膜盒式端面密封平衡直径的影响[J]. 火箭推进, 2021,47(2): 54-60.

- [4]杜鹏宇, 盛杰, 李建立. 机械密封端面比压影响因素分析[J]. 北京石油化工学院学报, 2013,21(4): 22-25.

- [5]李彦启, 刘启东, 刘合荣, 等. 基于热力耦合的镶嵌式机械密封端面变形分析[J]. 润滑与密封, 2021, 46(9): 113-119.

- [6]侯志刚, 丛小朋, 李进敏, 等. 浮动油封端面比压的参数分析及实验研究[J]. 机床与液压, 2023, 51(11): 140-144.

- [7]孙见君, 魏龙, 朱洪生. 弹簧比压可控振动可测型机械密封试验装置[J]. 石油机械, 2002, 30(2): 25-28.

- [8]王财生. 机械密封有限元分析及滑动面润滑性能研究[D]. 上海: 华东理工大学,2013.

- [9]姚翠翠. 船舶尾轴机械密封端面比压研究及对密封性能影响[D]. 青岛: 青岛理工大学, 2014.

- [10]张小平, 赵玉龙, 杨军, 等. 低温轴承和动密封试验的试验检测系统及集成试验系统: CN 211784279 U[P]. 2020-10-27.

- [11]SUN G Y, QIN D Y, LAN T T. Optimization of MAC algorithm based on IEEE 802.15.4 in indoor positioning system[J]. High Technology Letters, 2021, 27(1):86-94.

- [12]北京航天动力研究所. 液体火箭发动机涡轮泵机械密封端面比压测量装置和方法: CN 114279610 B[P]. 2023-07-14.

- [13]北京航天动力研究所. 一种机械密封端面比压自动测试系统及方法: CN 115541210 A[P]. 2022-12-30.

- [14]李迪, 杨银堂, 石佐辰, 等. 一种适用于IEEE802.15.4(ZigBee)标准的2.4 GHz CMOS射频收发机设计[J]. 电子学报, 2015, 43(5): 1021-1027.

- [15]王琪, 赵建刚, 韩天夫, 等. 超高温高压流变仪中高精度压力控制系统的实现[J]. 地质装备, 2018, 19(2): 19-21.

- [16]褚卫华, 谢明伟. 燃气发生器供气多级调压控制策略与实现方法[J]. 火箭推进, 2021,47(3): 60-66.

- [17]赵敏敏, 黄乐, 张岐, 等. 基于Ansys的O形橡胶密封圈密封性能及可靠性研究[J]. 橡胶工业, 2020,67(2): 131-134.

- [18] 杜晓琼, 陈国海, 闫晓亮, 等. 考虑安装过程的O形密封圈有限元分析模型[J]. 液压与气动, 2017(10): 27-33.

- [19]宋庭新, 李轲. 基于OPC UA的智能制造车间数据通信技术及应用[J]. 中国机械工程, 2020,31(14): 1693-1699.

- [20]赵晓慧, 张金容, 单磊, 等. 基于差动气动增压装置的多次启动一体化动力系统特性[J]. 火箭推进, 2022, 48(1): 22-29.